©Copyright Task Force Tips LLC 2011-2018

LIG-010 May 29, 2018 Rev05

12

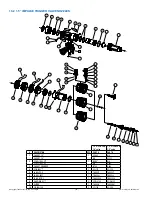

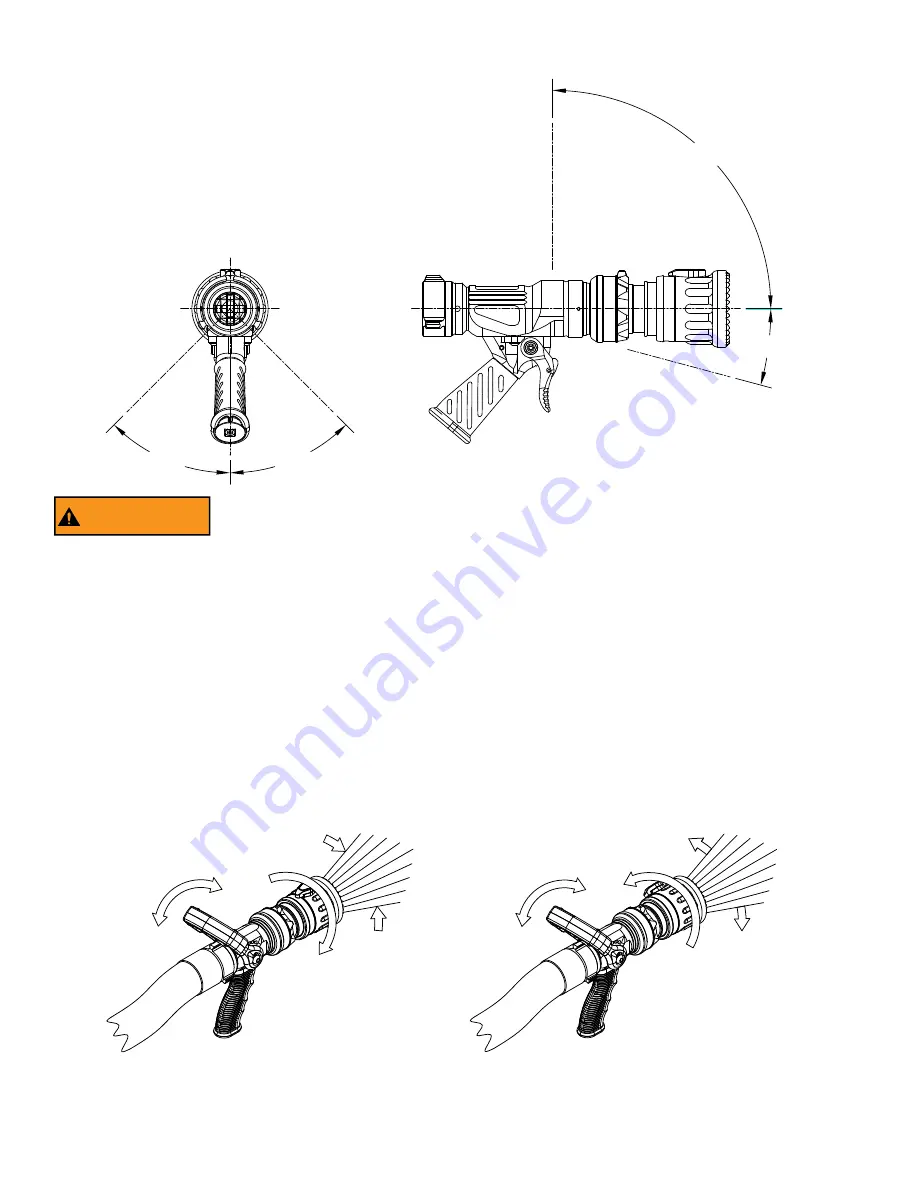

5.2 PATTERN AND FLUSH CONTROL

5.2.1 PATTERN CONTROL

TFT’s nozzles have full pattern control from straight stream to wide fog. Turning the stream shaper clockwise (as seen from the

operating position behind the nozzle) moves the shaper to the straight stream position. Turning the shaper counterclockwise will

result in an increasingly wider pattern.

Since the stream trim point varies with flow, the stream should be “trimmed” after changing the flow to obtain the straightest and

farthest reaching stream. To properly trim the stream, first open the pattern to narrow fog. Then close the stream to parallel to give

maximum reach.

Note: Turning the shaper further forward will cause stream crossover and reduce the effective reach of

the nozzle.

The nozzle reaction is greatest when the shaper is in the straight stream position. The nozzle operator must be prepared for a

change in reaction as the pattern is changed.

Care must be taken to avoid dents or nicks in the nozzle tip because they can seriously affect the stream reach.

OFF

ON

FLOW

COUNTER-

CLOCKWISE

OFF

ON

FLOW

CLOCKWISE

5.1.4.3 NORMAL OPERATING POSITION

45°

15°

90°

45°

Horizontal

Slow Closer

Operating Range

Slow Closer

Operating Range

WARNING

The Slow Close Feature relies on a fluid and air combination in the pistol grip. For proper function,

the pistol grip should be within its normal operating position. The normal operating position

is with the nozzle horizontal or pointing up with the pistol grip within 45 degrees of vertical.

Releasing the trigger suddenly outside of the normal orientation will likely result in faster shut-off

causing a higher pressure spike and increasing the risk of a burst hose. Do not suddenly release

the trigger when operating outside of the nozzle’s normal orientation.