©Copyright Task Force Tips LLC 2011-2018

LIG-010 May 29, 2018 Rev05

13

5.2.4 FLUSH CONTROL

Small debris passes through the debris screen (if equipped) and may get caught inside the

nozzle. This trapped material will cause poor stream quality, shortened reach, and reduced

flow. To remove small debris, the nozzle may be flushed as follows:

• While still flowing water, rotate the shaper counterclockwise (as viewed from behind

the nozzle) to the flush position. (increased resistance will be felt on the SHAPER or

RING as the nozzle goes into flush) This will open the nozzle allowing debris to pass

through.

• During flush the nozzle reaction will decrease as the pattern becomes wider and

the pressure drops. The nozzle operator must be prepared for an increase of nozzle

reaction when returning the nozzle from the flush position to retain control of the nozzle.

• Rotate the selector ring out of flush to continue normal operations.

WARNING

Large amounts or pieces of debris may be unflushable and can reduce the flow of the nozzle

resulting in an ineffective flow. In the event of a blockage, it may be necessary to retreat to a

safe area, uncouple the nozzle and remove debris.

5.2.3 FOG ANGLE ADJUSTMENT

Typically the G-Force is factory set with the tactile indicator in the top position for straight stream. The fog angle can be adjusted

while keeping the tactile indicator on top by following the steps in figure 5.2.3. You will need a new shaper label if you change the

fog angle adjustment.

1)

Remove or cut the shaper label.

2)

Loosen the clamp ring

with a pin spanner.

3)

While keeping the tactile indicator

or lock out lever on top,

rotate the shaper guide

to obtain the desired fog angle.

4)

Tighten the clamp ring

with a pin spanner.

5)

Apply a new shaper label.

Figure 5.2.3

Fog Angle Adjustment

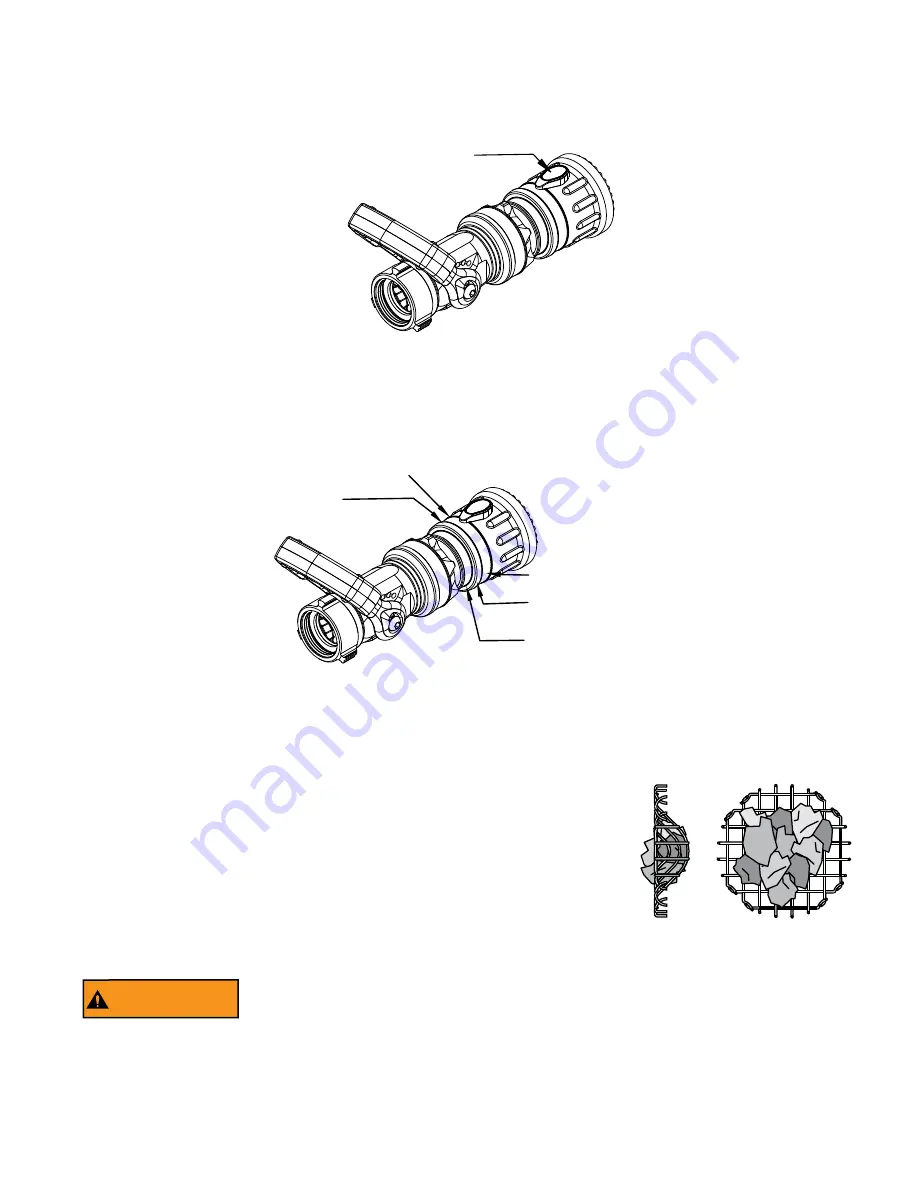

5.2.2 SHAPER TACTILE INDICATOR

The G-Force has a tactile indicator on the stream shaper. The tactile indicator allows the stream shaper position (and fog angle) to

be determined by feel rather than by sight. The fog angle can be adjusted (see section 5.2.3) so that a desired fog angle is achieved

when the tactile indicator in on top of the nozzle. The G-Force has an optional detent to aid in returning to a known fog angle. Note:

The fog angle will change as flow and pressure change (becoming wider with increased flow).

TACTILE INDICATOR

(MOVES WITH BUMPER)

Figure 5.2.2

Shaper Tactile Indicator