30

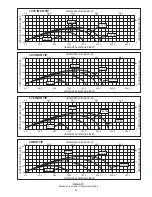

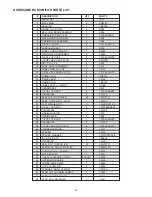

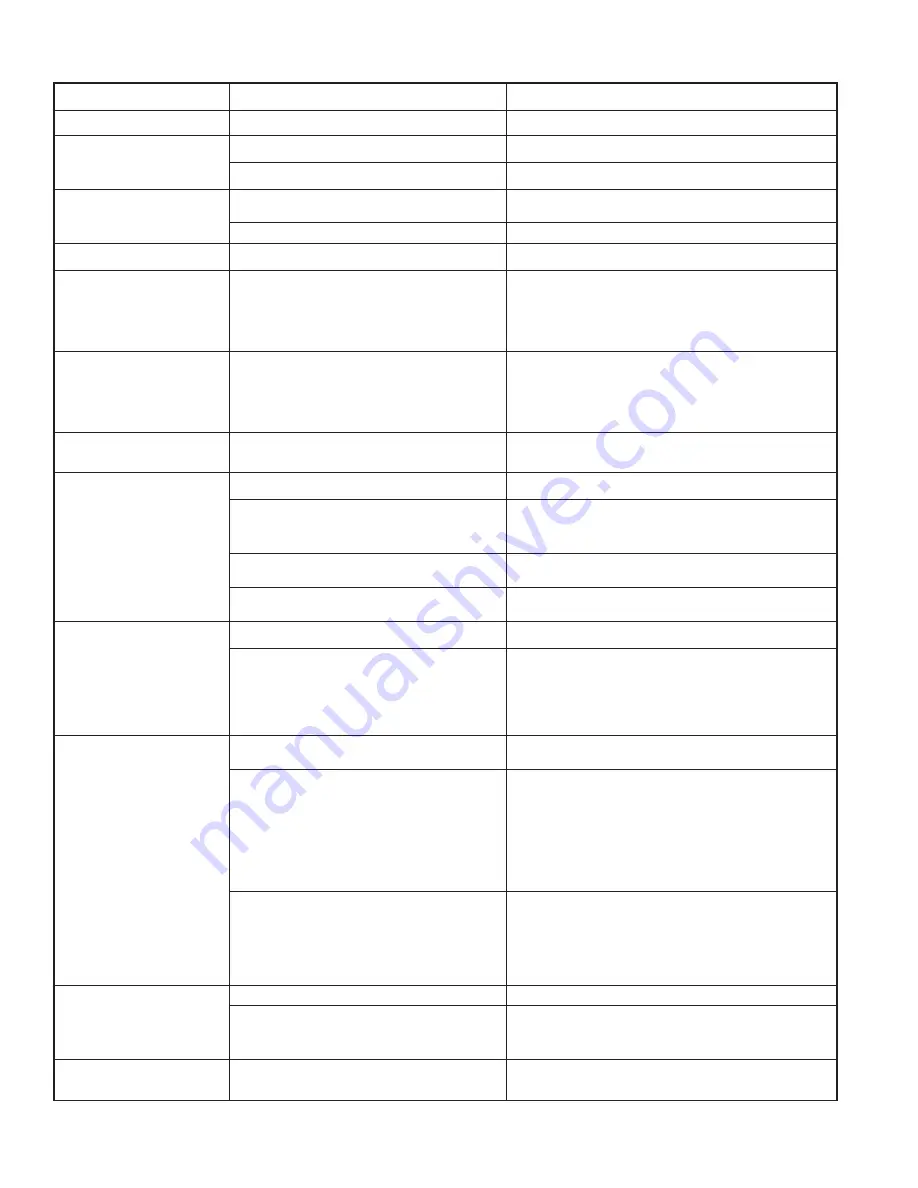

7.0 TROUBLE SHOOTING

SYMPTOM

Leaks

Elevation Binding

Horizontal Rotation Binding

One Axis Fails To Operate

From Any Control Station

Vertical/Horizontial axis will

not speed up

No Power LED

Power LED On But No

Operation

Operation only from monitor

operator station. STOW, &

OSC LED’s on remote station

blink slowly when button

pressed.

Operation only from monitor

control station

Vertical/Horizontial axis runs

only in fast speed

Vertical/Horizontial axis only

runs ~5 seconds and then

stops.

STOW & OSC LED’s on

mnitor control station blink

rapidly when pressing

UP/DOWN or RIGHT/LEFT

button.

Unable to program STOW

patte.

POSSIBLE CAUSE

Debris or damage in seal area

Debris or damage to elevation drive parts

Lack of lubricant

Debris or damage to horizontal drive parts

Lack of lubricant

Incorrect communication wiring

Communication board code version incompatible

Loose motor wiring connection

Bad

control board

Bad motor

Bad membrane switch

Loose encoder wiring connection

Bad motor encoder

Polarity reversed

Low voltage due to:

- wire gauge too small

- wire length too long

- poor connection

- inadequate apparatus electrical system

motor

Loose encoder wiring connection

Bad motor encoder

Loose encoder wiring connection

Bad motor encoder

Loosen encoder wiring connection.

Bad motor encoder.

Program enable timer expired.

REMEDY

Clean out debris or replace damaged parts

Clean out debris or replace damaged parts

Grease, see section 8.1

Clean out debris or replace damaged parts

Grease, see section 8.1

Check wiring and reverse polarity

Check connections and wiring per section 5.1.2

Check blue/white communication wiring

Verify code versions on monitor and all operator stations

Check axis motor connection

Interchange motor control boards and check if problem

persists with same axis, If not, replace motor control

board.

Interchange motor control boards. Check if problem

persists with same axis, If yes, replace motor.

Replace membrane switch / operator station

Check axis encoder connection

Interchange motor control boards. Check if problem

persists with same axis. If yes, replace motor.

Remove encoder cover and check for RED light just below

disk. If no light, encoder is bad. Replace motor.

Check axis encoder connection

Interchange motor control boards. Check if problem

persists with same axis. If yes, replace motor.

Remove encoder cover and check for RED light just below

disk. If no light, encoder is bad. Replace motor.

Check axis encoder connection.

Interchange motor control boards. Check if problem

persists with same axis. If yes, replace motor.

Remove encoder cover and check for RED light just below

disk. If no light, encoder is bad. Replace motor.

Check axis encoder connection.

Replace motor.

Cycle power to clear encoder fault.

Cycle power and enter STOW programming mode within

1 minute