©Copyright Task Force Tips LLC 2020

LIA-335 May 11, 2020 Rev00

4

3.1 SPECIFICATIONS

MODEL

IN-LINE STRAIGHT

IN-LINE PIVOTING

IN-LINE 45°

Weight lb (kg)

8.0 (203)

8.0 (203)

9.6 (244)

Length inches (mm)

12.4 (312)

14.4 (366)

11.4 (289)

Width inches (mm)

5.6 (143)

5.6 (143)

Right 8.1 (206)

Left 8.8 (224)

Height inches (mm)

8.1 (206)

8.1 (206)

9.4 (238)

Waterway Size inches (mm)

2.5 (64)

Maximum Operating Pressure psi (bar)

300 (20)

Standard Inlet Coupling inches (mm)

2.5 (64) Female Swivel

Standard Outlet inches (mm)

2.5 (64) Male Rigid

2.5 (64) Male Rigid

Pivoting ±20°

2.5 (64) Male Rigid

Operating Temperature Range of Fluid

33° to 120°F (0° to 50°C)

Storage Temperature Range

-40° to 150°F (-40° to 65°C)

Materials Used

Aluminum 6000 series hard anodized MIL8625 class 3 type 2,

stainless steel 300 series

Table 3.1

3.2 USE WITH SALT WATER

Use with salt water is permissible provided the equipment is thoroughly cleaned with fresh water after each use. The service life of

the equipment may be shortened due to the e

ff

ects of corrosion, and is not covered under warranty.

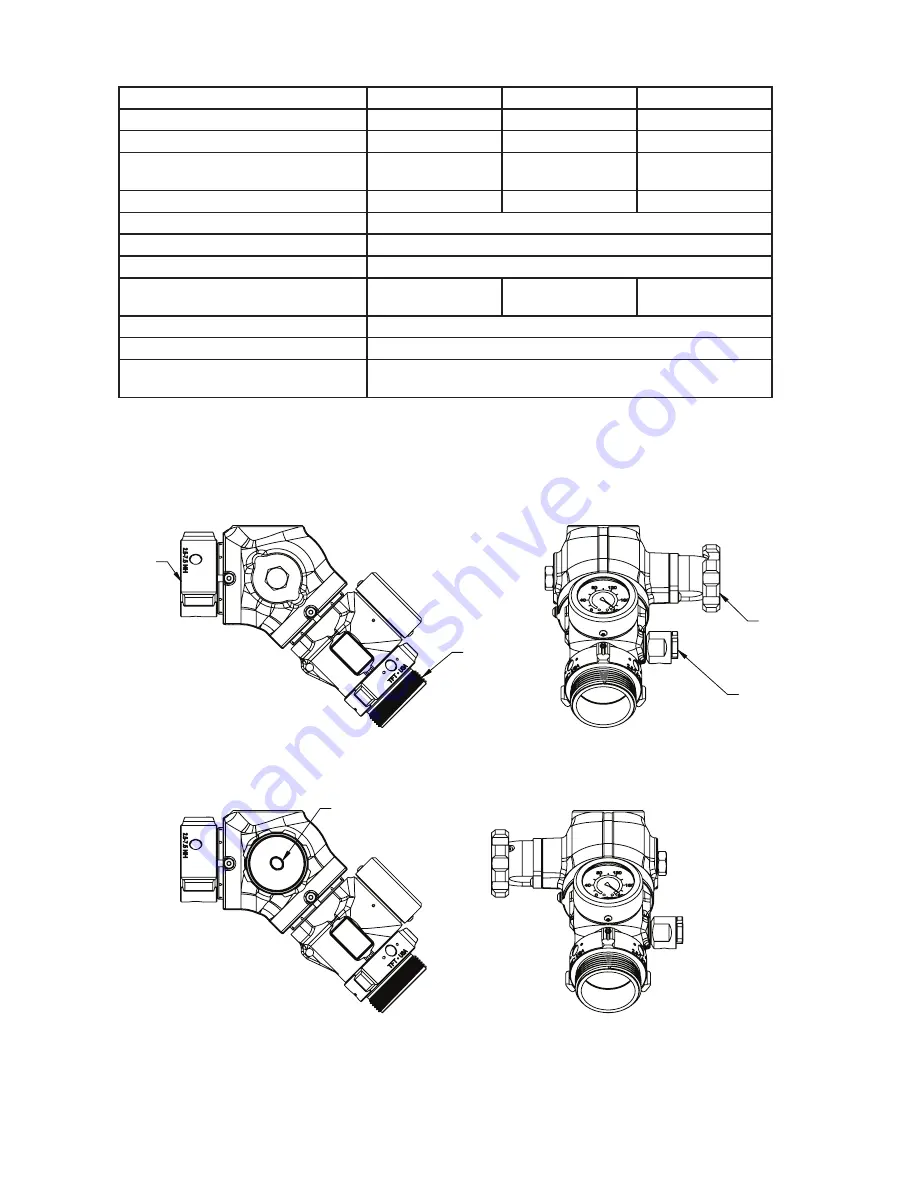

3.3 VARIOUS MODELS AND TERMS

VALVE POSITION

INDICATOR

FIXED

OUTLET

INLET

COUPLING

SLOW

CLOSE

KNOB

BLEED

VALVE

IN-LINE GAUGE WITH 45° RIGHT VALVE

IN-LINE GAUGE WITH 45° LEFT VALVE

Figure 3.3A