©Copyright Task Force Tips, Inc. 2016-2017

LIA-540 September 25, 2017 Rev03

3

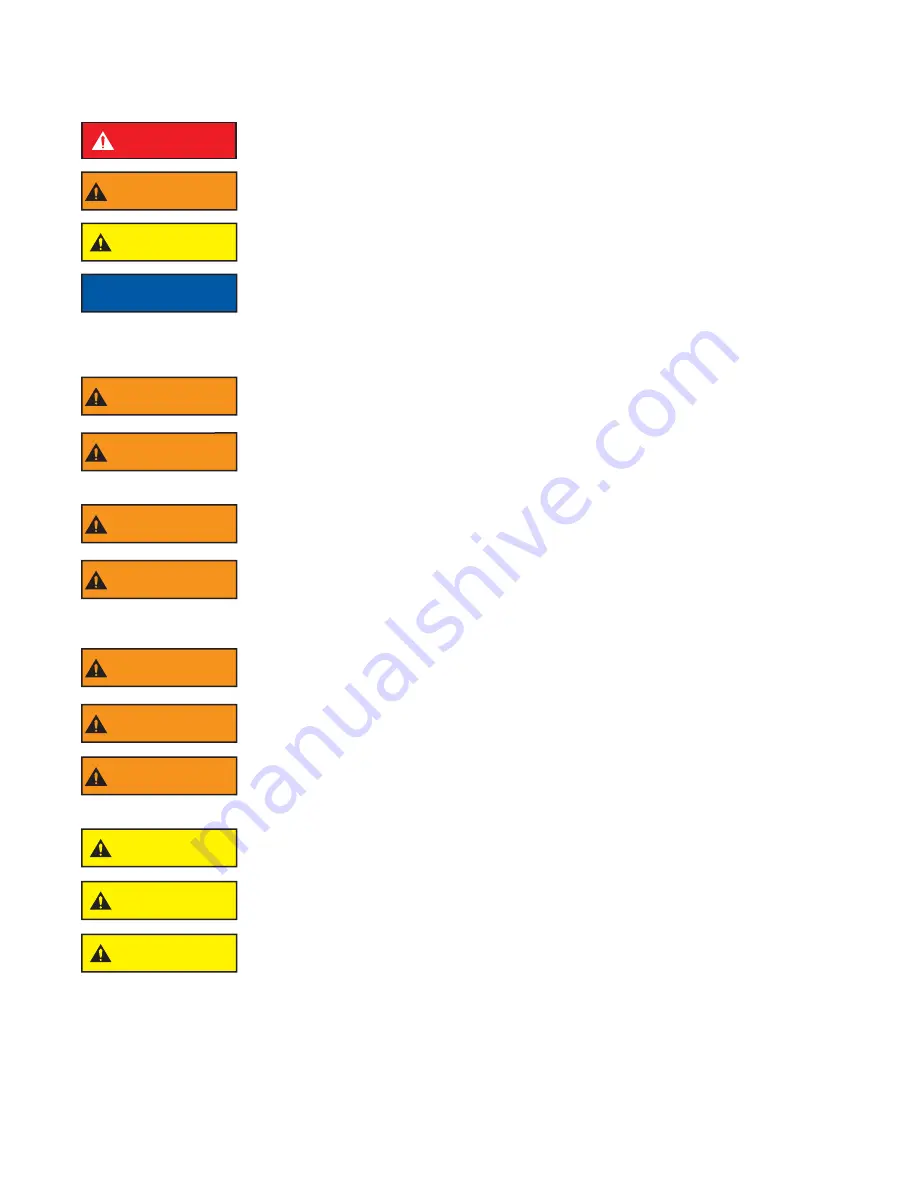

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identifi ed by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI standard Z535.6-2006, the defi nitions of the four signal words are as follows:

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

2.0 SAFETY

WARNING

Quick changes in valve position can cause high pressure spikes due to water hammer and may

result in damaged equipment which could lead to injury or death. Open and close the valve

slowly to avoid water hammer.

WARNING

The Pressure Relief Valve will open to relieve excess pressure but it may not have enough

fl ow capacity to protect against large pressure spikes such as those caused by water hammer.

Excess pressure can cause equipment failure and directly or indirectly lead to injury or death.

Always operate valves slowly to avoid the risk of water hammer.

WARNING

Injury or death can result from burst hoses and fi ttings. Be sure the pressure relief valve is set

at the proper pressure for the type of hose and equipment you are using. See NFPA 1961 and

NFPA 1962.

WARNING

Injury or death may occur by attempting to use a damaged valve. Per NPFA 1962, the device

shall be inspected and tested at least quarterly. Before use, inspect for damage resulting from:

• Failure to drain valve followed by exposure to freezing conditions

• Exposure to temperatures in excess of 160 degrees F

• Missing parts, physical abuse

WARNING

This equipment is intended for use by trained personnel for fi refi ghting. Its use for other

purposes may involve hazards not addressed by this manual. Seek appropriate guidance and

training to reduce risk of injury.

WARNING

Kinks in supply hose may reduce water fl ow and cause injury or death to persons dependant on

water fl ow. Avoid tight bends to minimize risk of hoseline kinks.

WARNING

The valve may be damaged if frozen while containing signifi cant amounts of water. Such damage

may to diffi

cult to detect visually and can lead to possible injury or death. Any time the valve

is subject to possible damage due to freezing, it must be hydrostatically tested by qualifi ed

personnel before being considered safe for use.

CAUTION

Maximum operating pressure 300 psi (21 bar). Do not exceed 300 psi (21 bar) on either side of

the valve.

CAUTION

Valve must be properly connected. Mismatched or damaged connectors may cause leaking or

uncoupling under pressure and could cause injury.

CAUTION

Use with salt water is permissible provided the LDH Gated Wye is thoroughly cleaned with fresh

water after each use. The service life of the LDH Gated Wye may be shortened due to the eff ects

of corrosion and is not covered under warranty.