©Copyright Task Force Tips, Inc. 2016-2017

LIA-540 September 25, 2017 Rev03

4

3.0 GENERAL INFORMATION

The LDH Gated Wye is a lightweight, low friction-loss valve that can be used in many water distribution applications. Dual robust

valve mechanisms from the TFT Ball Intake Valve are streamlined to a large waterway for the ultimate in versatility. Valve seats are

fi eld replaceable, Devices include a 300PSI pressure gage and quarter turn air vent and drain valve. Two robust carrying handles

make for easy deployment. A polymer bearing ring prevents galvanic corrosion on LDH couplings.

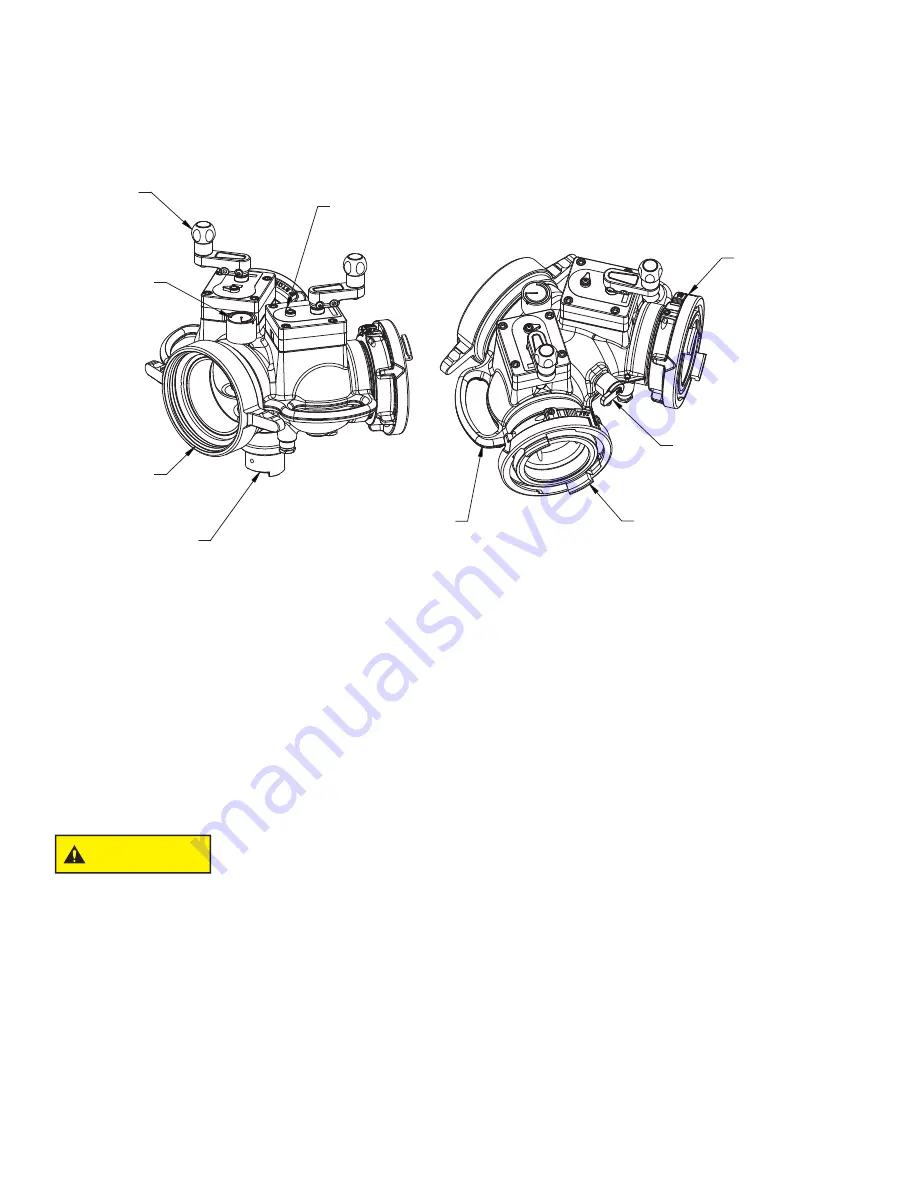

3.1 PARTS IDENTIFICATION AND MODELS

CRANK

SIDE A

COUPLING

PRESSURE

GAUGE

PRESSURE

RELIEF VALVE

VALVE POSITION INDICATOR

CARRYING HANDLE

SIDE B

COUPLING

AIR VENT & DRAIN

SIDE B

COUPLING

3.2 SPECIFICATIONS

Dual LDH outlet waterway size (at valve seat): 3.65” (93mm)

Inlet waterway size: 5.5” for 6” Storz and 6” Threaded couplings, 4.5” for all other couplings.

LDH Valve meets NFPA 1965 slow close requirement.

Maximum Operating Pressure: 300 psi (20 bar)

Hydrostatic Proof Test Pressure: 900 psi (62 bar)

Temperature Rating*: -25°F to 135°F (-32°C to 57°C)

*For temperatures below 32°F (0°C), valves must be drained after use to avoid damage. See section

2.0 SAFTEY

.

3.3 CORROSION

Hose couplings are attached using polymer bearing rings which provide electrical insulation to help galvanic corrosion. The parts are

then hard anodized, and fi nally powder coated, inside and out, to help prevent corrosion. The eff ects of corrosion can be minimized

by good maintenance practice. See section

6.0 MAINTENANCE

.

CAUTION

Dissimilar metals coupled together can cause galvanic corrosion that can result in the inability

to unscrew the threads or complete loss of thread engagement over time. Per NFPA 1962

(1998 edition), if dissimilar metals are left coupled together, an anti-corrosive lubricant should

be applied to the threads. Also the couplings should be disconnected and inspected at least

quarterly.

3.4 USE WITH SALT WATER

Use with salt water is permissible provided valve is thoroughly cleaned with fresh water after each use. The service life of the valve

may be shortened due to the eff ects of corrosion and is not covered under warranty.