3

The PRO/pak Portable Foam System is a very versatile eductor-type foam application appliance. It can be used with 0.1%-1% Class A

foam concentrates for wildland, rural and urban fire suppression on Class A fuels (wood, paper, combustible materials). On Class A

materials the PRO/pak is intended to be used for direct extinguishment, overhaul, and wetting of fuels. Some foam concentrates are

corrosive, we recommend using only Class A concentrates that have received USDA and USFS approval.

On Class B materials the PRO/pak is primarily intended to be used for vapor suppression. It can be used with 1% and 3% AFFF

concentrates on flammable liquids that do not contain alcohol. It can be used with 3% and 6% Alcohol Resistant AFFF Class B

concentrates on flammable liquids containing polar solvents. It can also be used with 3% X 6% or 6% Class B foam concentrates.

When ever possible back up the PRO/pak with additional water/foam capabilities for added safety.

The The Pro/pak can be used on ignited liquid fuels, but it's foam application rate is very limited. Based on NFPA 11 this unit should not

be used on ignited Class B fuels with an area greater than 120 square feet (10 x 12 feet) or 11 square meters. The PRO/pak should not

be used on burning Polar Solvents with an area greater than 60 square feet (6 x 10 feet) or 5.5 square meters.

The PRO/pak is designed for Class A and Class B foam concentrates, but it has been used with other concentrates for other uses.

Class

B

If you intend to use the PRO/pak for liquids other than Class A and Class B concentrates and water, we urge you to contact the Task

Force Tips Engineering Department. The use of other liquids may void the warranty and subject the user to hazzards not addressed in

3.0 GENERAL INFORMATION

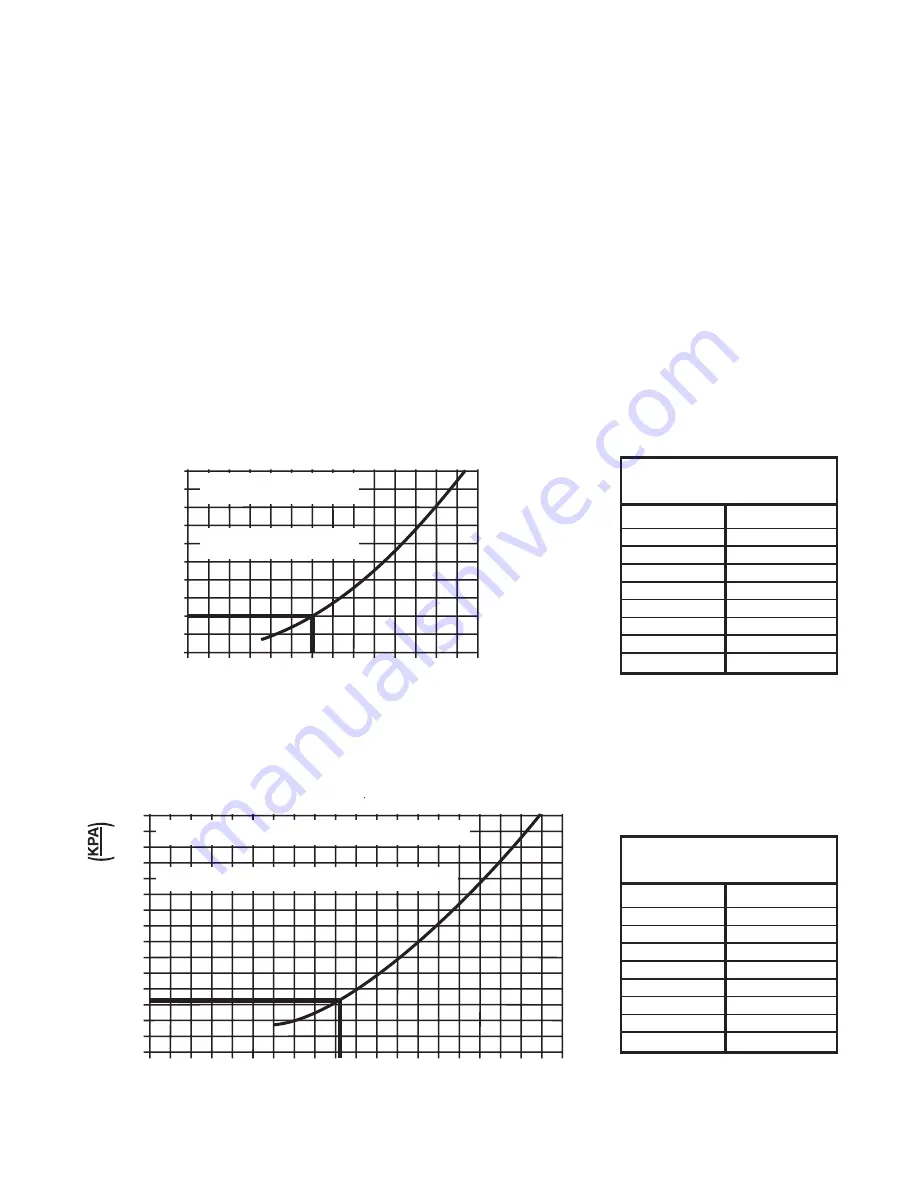

0

0

FLOW (GPM)

PRO/pak FLOW CHARACTERISTICS (with valve fully open)

INLET

PRES

SURE

(PSI)

20

18

2

6

16

14

12

10

4

24 26

22

8

28

50

150

350

250

450

100

300

200

400

500

MAXIMUM OPERATING

PRESSURE = 500 PSI

MINIMUM OPERATING

PRESSURE = 40 PSI

MINUTES TO USE 2½ GALLONS

OF CONCENTRATE AT 12 GPM

PERCENT

0.1

0.2

0.3

0.4

0.5

1

3

6

MINUTES

208

104

69

52

42

21

7

3.5

PERCENT

0.1

0.2

0.3

0.4

0.5

1

3

6

MINUTES

208

104

69

52

42

21

7

3,5

MINUTES TO USE 10 LITERS

OF CONCENTRATE AT 45 l/min

0

0

FLOW (L/MIN)

50

40

30

10

60

20

70

80

100

90

2

6

14

10

18

4

12

8

16

22

20

24

26

28

30

PRO/pak FLOW CHARACTERISTICS (with valve fully open)

MAXIMUM OPERATING PRESSURE = 40 BAR

MINIMUM OPERATING PRESSURE = 3 BAR

INLET

PRES

SURE

(BAR)

100