8

TO SHUT DOWN

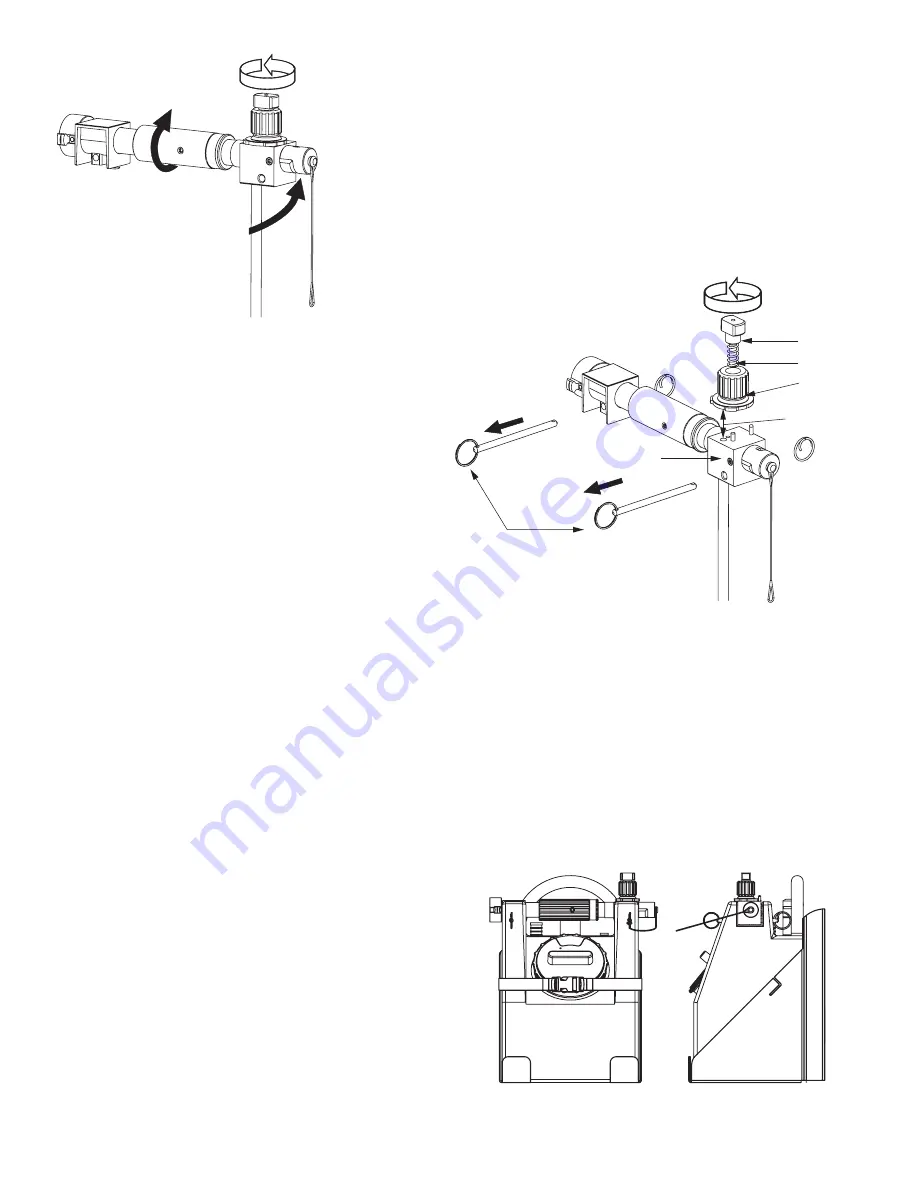

To prevent concentrate from drying in the foam passages the following is

recommended. While still connected to water supply, remove Circle

Cotters and Pull Pins. Remove Control Unit from tank. Attach the Cap

directly to the Quick-Connect on the Control Block. Turn the valve half way

on till the discharge is foam free. This will back flush a small amount of water

through the foam passage. Rotate the Percentage Knob back and forth to

make sure all foam passages are flushed.

INSTALL CAP

ROTATE

OPEN SLIGHTLY

PULL

CLEAN

UNSCREW

#1

#2

#3

#4

#5

TO CLEAN OUT IF PLUGGED

Remove screw #2, spring #3, and knob #4. Inspect the

underside of the knob. Make sure the foam passages are

clear. Do not scratch the flat face of the knob. Inspect the 2

holes in the top of the Control Block #5. If they are plugged,

pull pins #1, remove Block Assembly and clean out Pickup

Tube and holes.

6.7 SHUT DOWN AFTER USE (FLUSHING)

PRO/pak should be flushed with water after each use to prevent foam concentrate from drying out inside

of the Control Block and Percentage Knob.

1) Reduce pump pressure to 100 psi or less.

2) Remove the nozzle and/or hose from the quick-connect on the front of the Control Block.

3) Remove the Circle Cotters and pull out the two Pull Pins that hold the Control Unit to the tank.

4) Pull straight up to remove the Control Unit and Pickup Tube from the tank.

5) Make sure the Percentage Knob is NOT in the OFF position.

6) Install the Cap on the outlet of the Control Block.

7) Turn the Flow Control valve until a trickle of clean water is flowing out the end of the Pickup Tube.

8) Turn the Percentage Knob back and forth to make sure all foam passages are flushed.

9) Shut off water and reinstall the Control Unit on the tank and insert the Pull Pins and circle cotters.

10) Remove the Cap.

The exterior of the PRO/pak can be washed off with the hose or straight stream nozzle with the

percentage knob in the OFF position.

6.8 STORAGE

The PRO/pak can be stored with foam concentrate in it.

S

is recommended

the PRO/pak is

(See figure 6.8)

Make

sure the control block and valve assembly is mounted on the

tank and the fill port is securely closed to prevent evaporation.

torage in the upright position

to avoid foam

leaking when

not in use.

Figure 6.8

PRO/pak shown placed in a U-B

mounting bracket in an upright position.