9

PRO/pak will not make foam

Foam is Intermittent

Poor Quality Foam

SYMPTOM

Out Of Foam

Percentage Knob is OFF

Percentage Knob is plugged

Non-standard outlet hose being used which

is too long or too small in diameter

Foam tank is nearly empty

PRO/pak tilted

Air vents are plugged

Debris in nozzle

Debris under knob

Foam solution velocity too high

Foam gets thick when cold

POSSIBLE CAUSE

Refill Tank

Select desired percentage

Remove screw on Percentage Knob,

inspect and clean holes in top of control

block and foam passages in bottom of

Percentage Knob

Order long hose option TFT part U-HS6 or

U-HS25

Refill tank

Keep Twist Grip Horizontal

Make sure that the small black rubber

valve on the inside of the foam tank lid is

not stuck down with dried foam

concentrate

Inspect nozzle, look for plugged holes

Unscrew Knob, inspect and clean

Partially close Flow Control

Select Another Foam

REMEDY

7.0 TROUBLE-SHOOTING

9.0 SPECIFICATIONS

Turn the percentage knob to the OFF position. Use the hose, or hose and

straight stream nozzle, to rinse off the PRO/pak. Reset percentage knob to

proper percentage when finished.

For years of service, periodically inspect your PRO/pak. Make sure the hose

and three nozzles are in place. Look for debris in the bottom of the tank and

flush if necessary.

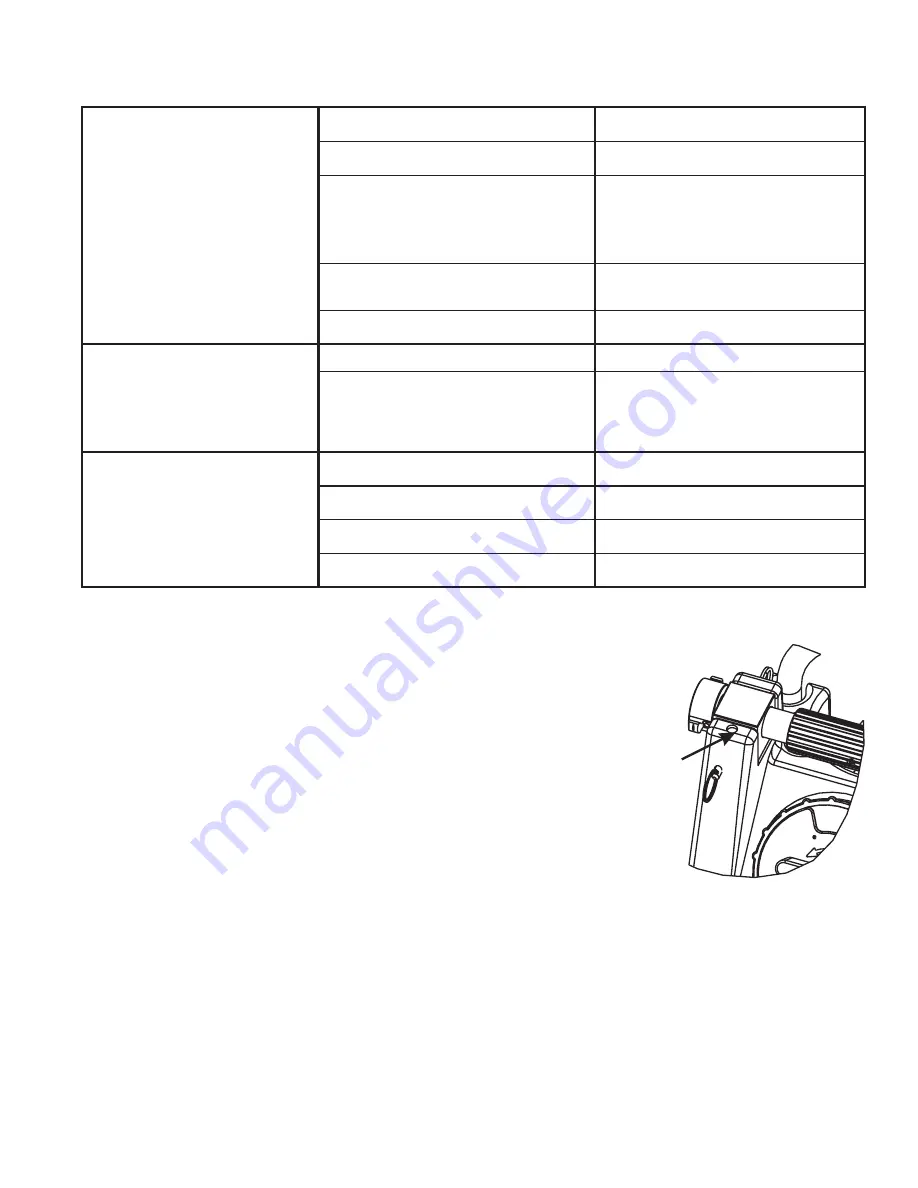

If the PRO/pak is often used for different foam concentrates, it may be helpful

to install a drain to aid in emptying the tank. Drill and tap the left front ear of the

tank and install a ¼" NPT Pipe plug. Plastic or Brass preferred.

Tank Capacity (to bottom of fill port)

2.5 U.S. gallons

9.5 liters

Nominal flow (all nozzles)

12 gpm at 100 psi

45 l/min at 6.8 bar

Weight Empty

11.5 lb

5.2 kg

Weight Full

30.1 lb

13.6 kg

Length x Width x Height

13.5 x 10.75 x 17 in

345 x 275 x 430 mm

Operating Pressure Max/Min

500/40 psi

40/3 bar

Straight Stream Nozzle Reach

50 feet at 100 psi

15 meters at 6.8 bar

Low Expansion Nozzle Reach

37 feet at 100 psi

11 meters at 6.8 bar

U.S. Units

Metric Units

8.0 CLEAN UP AND MAINTENANCE

8.1 DRAIN HOLE

DRILL 7/16" HOLE

TAP ¼" NPT

LEFT FRONT ONLY!