©Copyright Task Force Tips LLC 2003-2020

8

LIU-030 August 24, 2020 Rev10

7.0 OPERATION

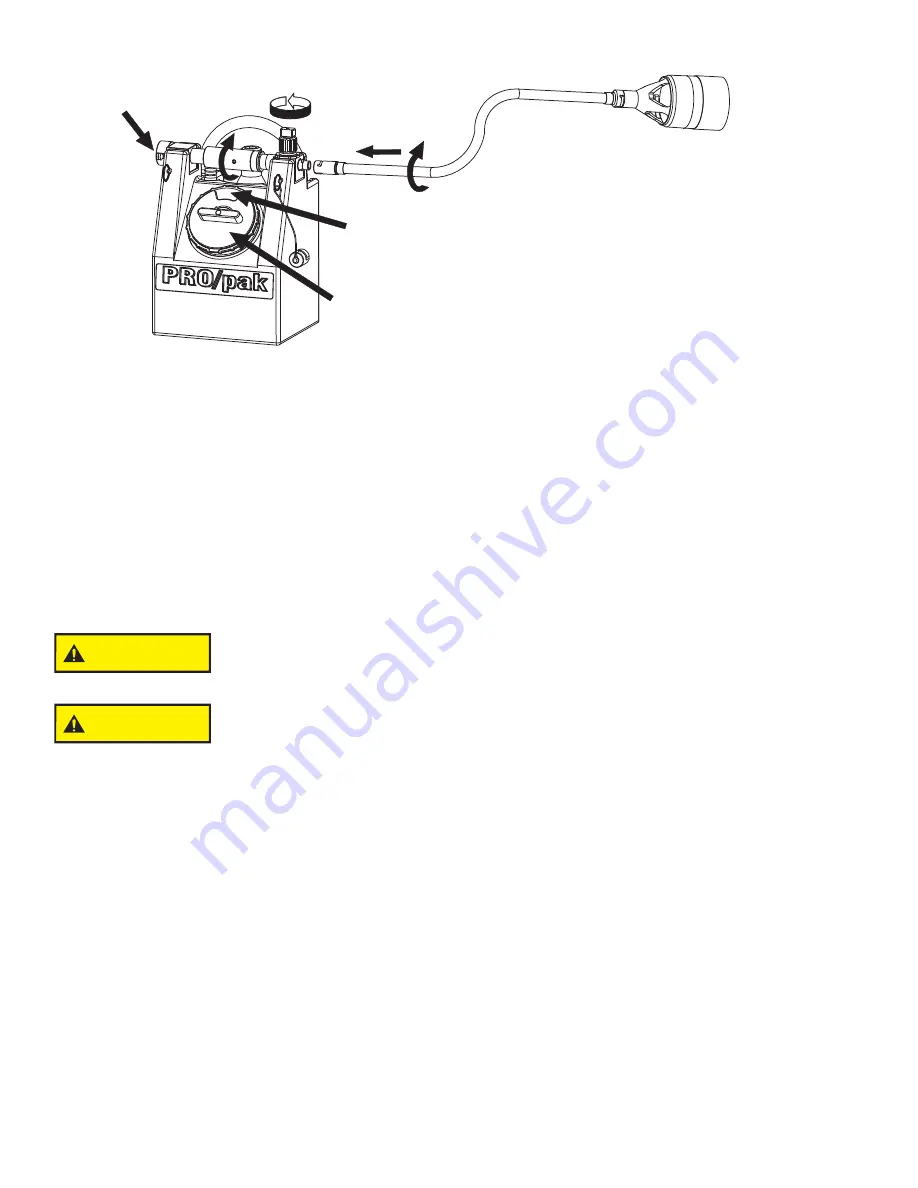

Figure 7.0

7.1 HOSE CONNECTION

Attach inlet fire hose to the coupling on the inlet end of the PRO/pak. Larger hoses may be used with an adapter. For maximum

maneuverability, we recommend attaching 1” hose to the PRO/pak itself.

7.2 FILLING THE TANK

Unscrew the fill port lid by turning counterclockwise. Fill tank to bottom of fill port. Agent may seep out the vents if overfilled. Close the fill

port lid by turning clockwise.

7.3 CONNECTING DISCHARGE HOSE AND NOZZLE

The nozzle may be attached directly to the quick-connect fitting on the control block or to the end of the outlet hose which is then

attached to the control block.

1. Align the marks on the quick-connect male fitting with the marks on the female fitting and push the two pieces together.

2. Twist the nozzle or hose one quarter turn to the right to latch the quick-connect fitting.

3. To remove fan nozzle, remove set screw.

4. Hose lengths available. TFT part U-HS6, U-HS12, and U-HS25.

7.4 SETTING CONCENTRATION

Remove the nut on top of the percentage knob and lift the knob to select the proper foam concentrate type. Replace the knob nut. Turn

the knob to the desired concentrate percentage. The percentage knob may be turned to the OFF position for water only use. Be sure to

use the foam manufacturer’s recommended concentrate ratio.

7.5 CONTROLLING FLOW

Pressurize the hose line. Turn the flow control valve to start water flowing through the PRO/pak. Flow may be reduced by partially

closing the control valve.

CAUTION

The PRO/pak’s eductor will not function if the back pressure from the outlet hose or nozzle is too

high. To reduce the risk of injury or death due to a non-functioning unit:

• Never use hose longer than the 25’ (7.5m) U-HS25 optional hose.

• Never add additional hose, or use other manufacturer’s hose assemblies and nozzles.

CAUTION

There is no check valve in the PRO/pak eductor system. Installing a shut off valve between the

PRO/pak and the fan nozzle can cause the agent tank to fill with water and dilute the agent

concentrate resulting in ineffective agent. Never install a shut off valve between the PRO/pak and

the fan nozzle.

k

a

p

/

O

R

P

k

a

p

/

O

R

P

PORTABLE MULTI PURPOSE FOAM SYSTEM

PATENT PENDING ó MODEL UM12

PUSH & TURN

TO ATTACH

CONTROL

FLOW

FILL

2.5 GAL

SELECTOR

WHEEL

CONNECT

SUPPLY

ADJUST %

START UP PROCEDURE

To Make Foam - Connect water supply. Attach the desired nozzle to

the Quick-Connect. Turn the Percentage Knob to the desired

percentage. Twist the Valve Handle to start water flow.