©Copyright Task Force Tips LLC 2002 - 2020

LKF-100 January 22, 2020 Rev20

5

3.0 GENERAL INFORMATION

This manual describes nozzles calibrated at 100 psi (7 bar) and 75 psi (5 bar). Contact the factory for data speci

fi

c to models

that operate with metric

fl

ow calibrations. ThunderFog, QuadraFog, and QuadraCup are economical, lightweight, and dependable

nozzles. Their rugged construction is compatible with the use of fresh water as well as

fi

re

fi

ghting foam solutions. Other important

operating features include:

• Quick-acting pattern control from straight stream to wide fog

• Fixed fog teeth

• Metal spinning fog teeth available on some models

• Easily

fl

ushable while

fl

owing to clear trapped debris

• Quick-change rear valve seat

• TFT’s 5-year warranty and unsurpassed customer service

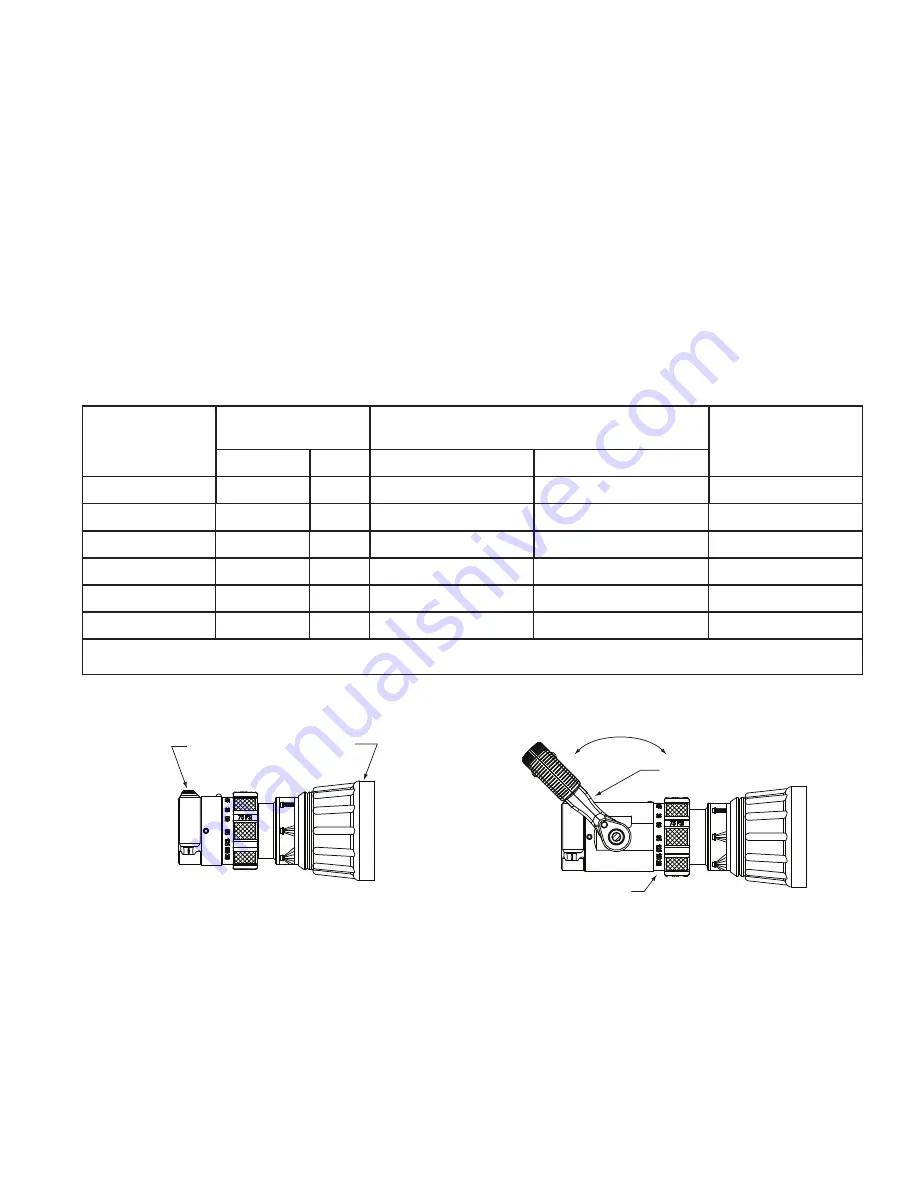

3.1 VARIOUS MODELS AND TERMS

The nozzle is available in several di

ff

erent models and inlet connections. Basic body styles are shown below.

Selectable Flow

: A nozzle with a discharge ori

fi

ce that can be set to a user selected position. In each position the nozzle acts as a

fi

xed ori

fi

ce nozzle.

Tip Only:

A nozzle without an integral ball shutto

ff

valve.

ThunderFog, QuadraFog, and QuadraCup nozzles are available in a variety of

fl

ow ranges and con

fi

gurations. All models deliver the

selected

fl

ow when the rated pressure is supplied to the nozzle. Flow settings and recommended hose sizes are:

SERIES

RECOMMENDED

HOSE SIZE

FLOW SETTINGS

@100 PSI (7bar)

NOZZLE TYPE

INCHES

MM

GPM

l/min

1” QUADRAFOG

3/4, 1

19, 25

5, 10, 24, 40

20, 40, 100, 150

Selectable Flow

1” QUADRAFOG

3/4, 1

19, 25

5, 10, 25, 40, 60

20, 40, 100, 150, 230

Selectable Flow

1.5” QUADRAFOG

1-1/2

38

30, 60, 95, 125

115, 230, 360, 475

Selectable Flow

1.5” QUADRACUP

1-1/2

38

30, 60, 95, 125

115, 230, 360, 475

Selectable Flow, Foam

1.5” THUNDERFOG

1-1/2 to 1-3/4

38 to 45

30, 60, 95, 125, 150, 200

115, 230, 360, 475, 550, 750

Selectable Flow

2.5” THUNDERFOG

1-1/2 to 2-1/2

38 to 64

95, 125, 150, 200, 250

360, 475, 550, 750, 1000

Selectable Flow

* Other threads, coupling sizes, or connector styles can be speci

fi

ed at time of order.

ThunderFog, QuadraFog, and QuadraCup nozzles are available in several models.

Table 3.1

HUNDER

T F

OG

Coupling

Shaper

HUNDER

T F

OG

Ball Valve Handle

Model Number

Serial Number

Operating Pressure

ON

OFF

A) TIP ONLY

Figure 3.1A

B) BALL VALVE

Figure 3.1B