©Copyright Task Force Tips, Inc. 2013-2014

LIS-011 December 15, 2014 Rev02

7

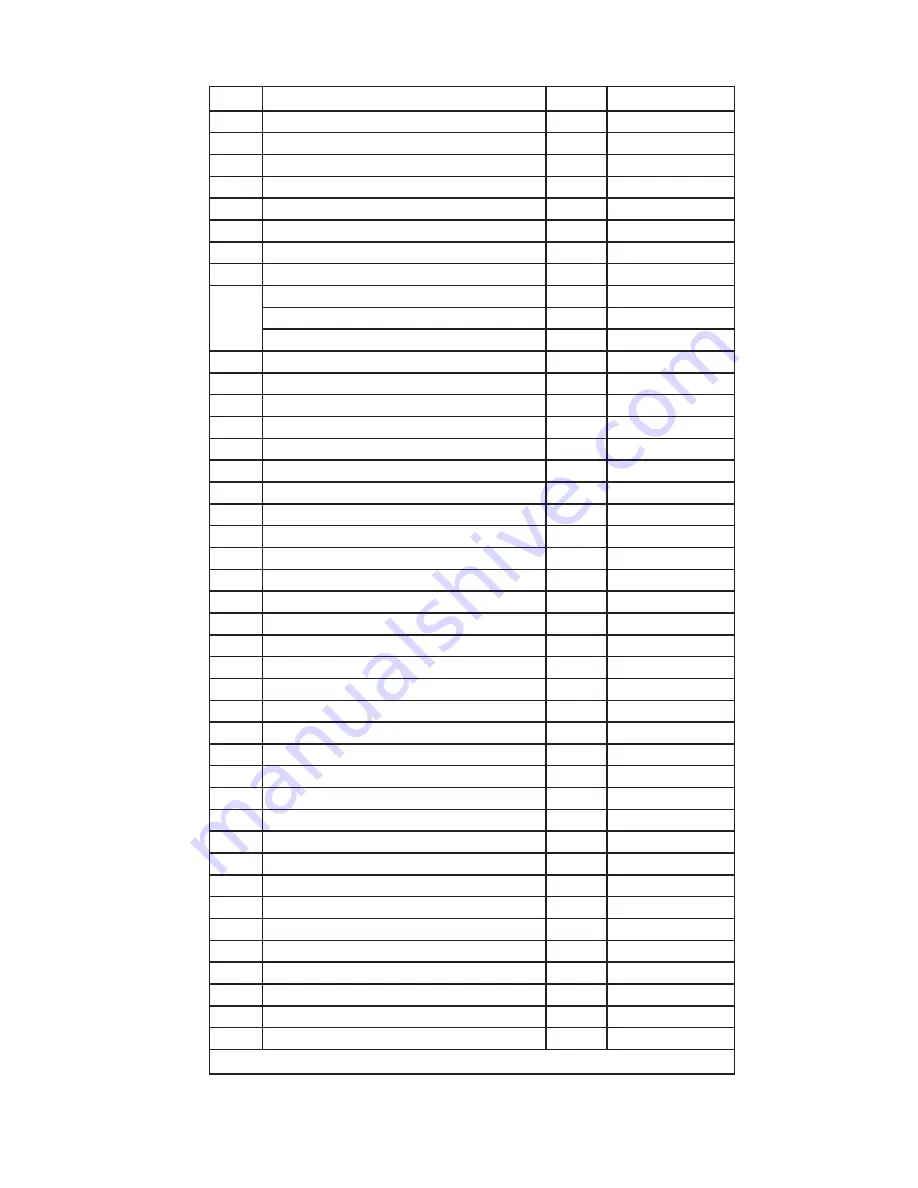

PARTS LIST

INDEX

DESCRIPTION

QTY.

PART

1

PIERCING NOZZLE STRIKING CAP

1

PA161

2

O-RING-125

9

VO-125

3

O-RING-012

1

VO-012

4

PIERCING NOZZLE STRIKING PLUG

1

PA162

5

BELLEVILLE WASHER

2

VM4903

6

7/16-14 NYLOCK HEX NUT

1

VT43-14LNT

7

3 PORT JUNCTION BLOCK

1

PA150

8

LABEL: BRAND

3

PA206

9

19" EXTENSION TUBE

2

PA110

40" EXTENSION TUBE

1

PA170

12" EXTENSION TUBE

1

PA230

10

GRIP MOUNT

1

PA250

11

GRIP SPACER

1

HM693-F

12

PISTOL GRIP - BLACK

1

HM692-BLK

13

WASHER

1

VM4901

14

3/8-16 X 1 SOCKET HEAD SCREW

1

VT37-16SH1.0

15

FLOW PATTERN EXTENSION SECTION

1

PA120

16

PIERCING POINT

1

PA141

17

NAME LABEL: TRANSFORMER PIERCING NOZZLE

2

PA205

18

LABEL: ROTARY VALVE OFF - RED

1

PA227

19

LABEL: ROTARY VALVE ON - BLUE

1

PA226

20

FOLLOWER

2

U251

21

3/8-24 X 3/8 DOG POINT

2

H515

22

LABEL: ROTARY VALVE - BLUE

1

PA228

23

O-RING-130 2

VO-130

24

VALVE BODY

1

PA221

25

CAP

1

PA224

26

O-RING-135

1

VO-135

27

SEAT

1

PA223

28

VALVE

1

PA222

29

INLET ADAPTER

1

PA225

30

3/16" SS BALL (34) PER RACE

68

V2120

31

PORT PLUG

2

B770

32

O-RING-134

2

VO-134

33

GASKET GRABBER

1

G606

34

COUPLING 1.5"

2

G690*

35

GASKET - 1.5" HOSE COUPLING

2

V3130

36

STORAGE BAG

1

PA200

37

MATE

1

PA264

38

NOZZLE BASE

1

PA261

39

HEX PORT PLUG

1

PA265

40

NOGGIN

3

PA262

41

SPINNER

3

PA263

* - CONSULT FACTORY FOR SPECIAL THREADS