©Copyright Task Force Tips, Inc. 1998 - 2009

LIM-035 June 15, 2009 Rev07

8

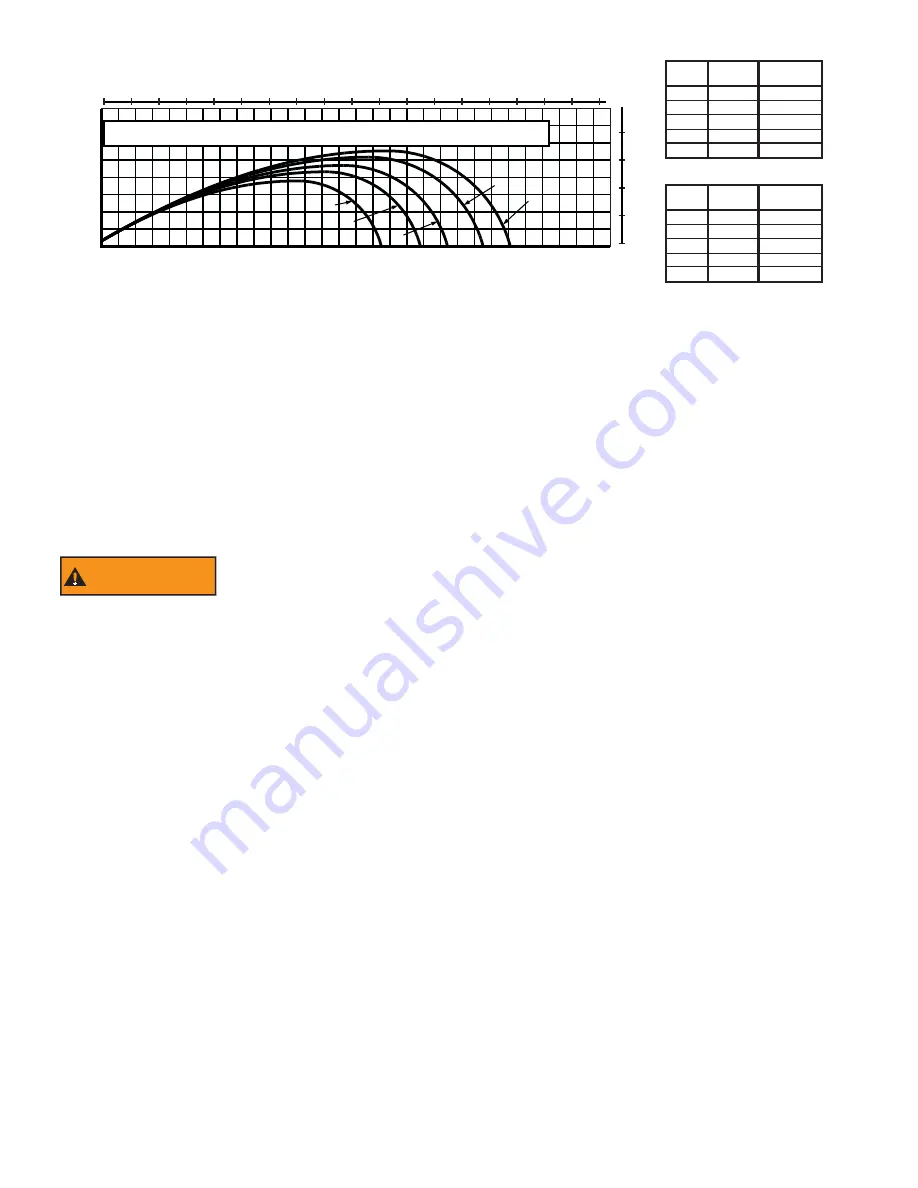

HORIZONTAL DISTANCE (FEET)

0

10

20

30

40

50

60

70

80

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

HORIZONTAL DISTANCE (FEET)

VER

TICAL

DIST

ANCE (FEET)

A

B

C

D

E

ZN, ZM AND MASTERSTREAM 1000, 150 PSI (10 BAR, 1000 KPA )

CURVE

A

B

C

D

E

GPM

FLOW

310

430

610

920

1200

LBS

REACTION

200

280

400

600

780

CURVE

A

B

C

D

E

LPM

FLOW

1200

1600

2300

3500

4500

KGF

REACTION

90

120

180

270

350

20

30

40

60

70

80

90

50

0

10

20

10

0

METERS

FIG 5 - ZN, ZM and Masterstream Nozzle Stream Trajectory

4.0 FLUSHING DEBRIS

Debris in the water may get caught inside the nozzle. This trapped material will cause poor stream quality, shortened reach and

reduced fl ow. To remove debris trapped in the nozzle:

1) Shut off fl ow to the nozzle.

2) Move the stream shaper to the wide fog position.

3) For ZN Nozzle: Unscrew baffl e using a 1-1/8 inch (28mm) socket.

For ZM Nozzle: Unscrew the bolt using 7/8” socket and remove baffl e.

For Masterstream Selectable Gallonage Nozzle: Turn fl ow selector on front of nozzle to “FLUSH” position.

For Masterstream Fixed Gallonage Nozzle: Remove nozzle to gain access to debris.

4) Remove debris. Flow water to fl ush if necessary.

5) Reassemble the nozzle. Tighten the baffl e on the Max Lite nozzle to 30 ft-lbs (40 newton-meters).

WARNING

Large amounts of debris may be unfl ushable and can reduce the fl ow of the nozzle resulting in

an ineffective fl ow. In the event of a blockage, it may be necessary to retreat to a safe area.

5.0 MAINTENANCE

Nozzles must be checked regularly to assure proper operation. Contact factory for parts lists and exploded views for particular

models.