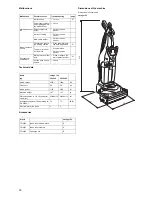

26

Preparation for operation/Operation

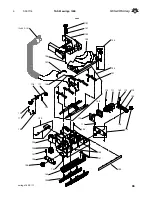

Electrical diagram

Filling water

Dosage:

Only use chemical products recommended by the manufacturer.

The dosing cap is marked for a 1% cleaning solution.

Dosing example:

Before the machine can be put into operation, you must connect

the two parts of the machine electrically and screw the handle

onto the body of the machine.

Use the assembly instructions on page two of these instruction of

use.

Caution:

Maximum permissible water temperature 35 °C/95 °F.

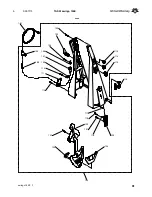

• Remove the tank from the machine by pulling

the tank unlocking device (1).

Hold the tank (2) with your other hand (2) so that

it cannot fall out of its bracket while being

unlocked. Pull the water tank out of the bracket.

• Remove the dosing cover. The dosing cap can

be removed from the filter housing by turning it

to the left.

• Fill up the fresh water tank up to the mark.

11

10

12

14

13

15

8

6

1

2

5

3

4

9

7

Y/G

WHITE

BLACK

BLACK

BROWN

GREEN

WHITE

WHITE

WHITE

BLACK

BLACK

RED

BLUE

GREEN

RED

WHITE

BLACK

GREEN

RED

WHITE

Y/G

BLACK

BROWN

RED

11

10

12

16

16

14

13

15

8

8

1

2

5

3

4

9

7

BLACK

BROWN

Y/G

WHITE

WHITE

Y/G

Y/G

WHITE

BLACK

BLACK

RED

BLUE

GREEN

BROWN

RED

Y/G

230V / 50-60Hz

100V / 50-60Hz

120V / 60Hz

13

14

15

16

- Wires kit base

- Circuit board

- Brush motor

- Wire kit vac/base

7

8

9

10

11

12

- Pressostat (for pump version)

- Pump or Electro valve

- Thermal protector pump

- Terminal block

- By-pass vacuum motor

- Microswitch

1

2

3

4

5

6

- Terminal block

- Main switch

- Vacuum switch

- Pump switch

- Wires kit electric panel

- Wires kit upper housing

WHITE

WHITE

WHITE

BLACK

GREEN

2

1

1

2

• The mark is indicated by a label on the side of

the fresh water tank.

Caution:

Wear protective gloves, goggles and the corresponding

(protective) work clothing when handling chemical products!

Caution:

Using other chemicals (e.g. chemicals containing chlorine or

hydrochloric acid) can damage or destroy the machine.

Dosage

Tank capacity

Dosing aid

1%

MAX

1 x MAX

• Use the dosing cap for the dosing. The dosing

cover can be removed from the filter housing by

turning it to the left.

• Fill the dosing cap with cleaning water up to the

marked level (26 ml =1%).

Empty the contents of the dosing cap into the

fresh water tank.

• Return the dosing cap back to the opening

provided.

Ensure that the dosing cap is turned in exactly

as shown in the illustration. The Taski lettering

must be at the bottom. Only in this way do the

ribs on the dosing cap fit into the cutouts

provided in the tank.

• Fit the filter housing onto the tank and lock it into

place.

In doing this, ensure that the filter housing lies

correctly on the tank. The locking device on the

front side of the tank is designed for this. (See

the detail in the illustration).

The tank could open by itself during cleaning.

• Replace the tank (1) in the machine again until

it locks into place and press the tank unlocking

device (2) into place again.

M A X

WATER LEVEL

LIVELLO ACQUA

WASSER NIVEAU

NIVEAU DE L`EAU

NIVEL DE L`AGUA

Temperature

+5°C + +35°C

+41°F + +95°F

M A X

WATER LEVEL

LIVELLO ACQUA

WASSER NIVEAU

NIVEAU DE L`EAU

NIVEL DE L`AGUA

Temperature

+5°C + +35°C

+41°F + +95°F

1

2

- 1% / 26ml -

- 1% / 26ml -

TASKI

1

2