GTS

Technical Manual

26. March 2013

Edition: V2.00/2013

5-41

Copyright © 2013, Diversey Inc.

05.

58.

10

br

us

h & mot

or

-

br

us

h mo

to

r b

elt

-

350

B_

V1

.00

.fm

5.7

Brush & Motor

5.7.1

Removing of brush motor belt

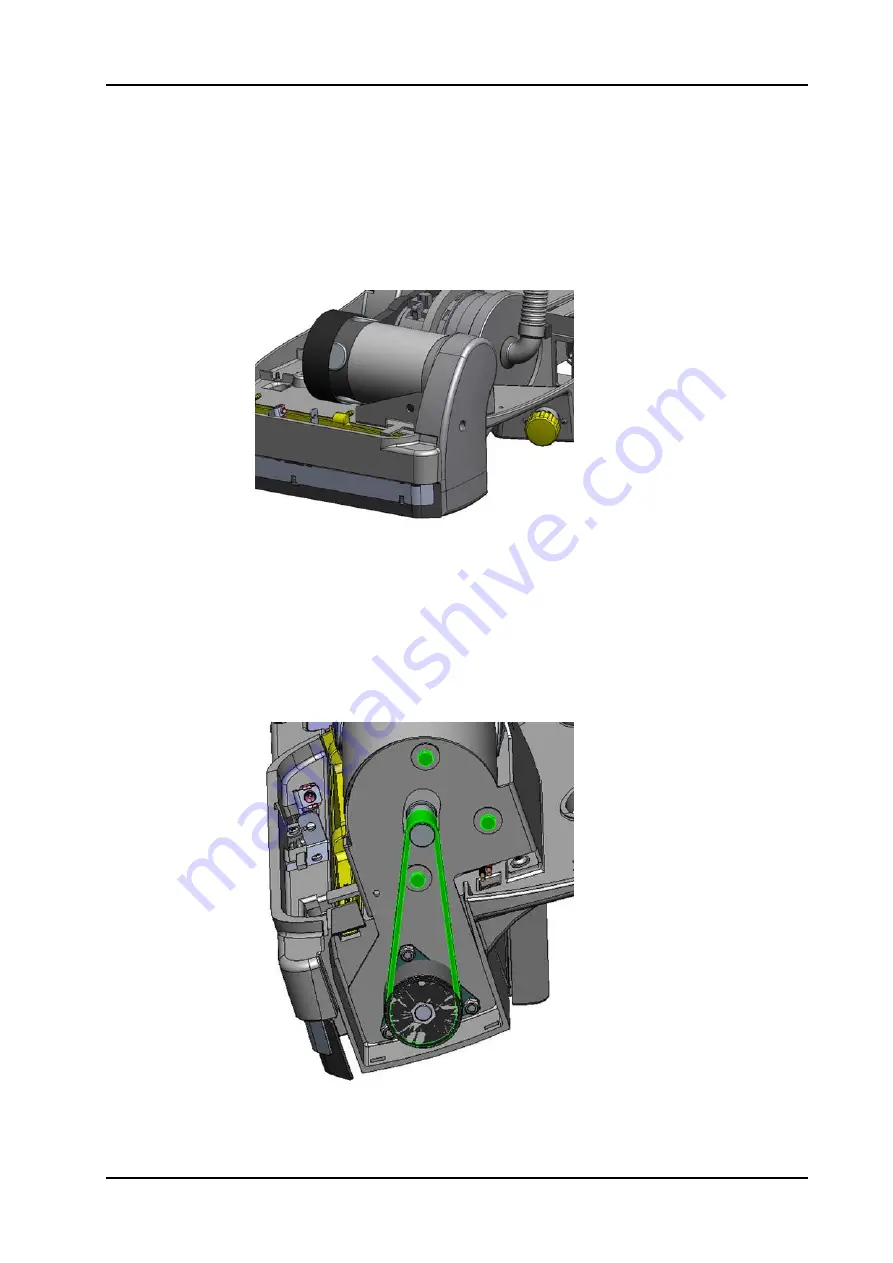

Picture 56: Brush and motor

•

Remove tank cover complete (06/101).

•

Remove recovery tank (06/121).

•

Remove screw (08/107) for belt cover (08/106).

•

Remove belt cover (08/106).

•

Untighten the 3 fixation screws (08/108) of the brush motor

(08/112) with a 10mm fork spanner/nut.

•

Remove the brush motor belt (08/110) as the tension is now

released.

Picture 57: Brush motor belt

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com