40

Service intervals

TASKI machines are high quality machines that have been checked for safety

at the factory by authorised inspectors. Electrical and mechanical components

are subject to wear and/or ageing after longer periods of use.

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Blade replacement

Cleaning or replacing the float (Indication for full recovery tank)

Disassembly:

Malfunctions

Transport

• Disconnect the battery from the machine using the battery disconnection

socket.

Transport the machine in an upright position.

Make sure that the machine is securely fastened within the transportation

vehicle and is secured against tipping over.

Refer to page 41 for the dimensions and weights.

Disposal

When it has reached the end of its operational life, the machine and its

accessories must be disposed of according to the national regulations. Your

TASKI partner can support you with proper disposal upon notification.

Batteries

The batteries must be removed from the machine before being disposed of

properly.

Used batteries must be disposed of in an environmentally appropriate way

according to the EU guidelines 2006/66//EEC

• In order to ensure the operational reliability and

availability of the machine, a service must be

carried out after 450 working hours (option: only

with an integrated hour counter) or at least once

a year.

Shorter intervals are necessary in case of rough environments or special

conditions of use and/or inadequate maintenance.

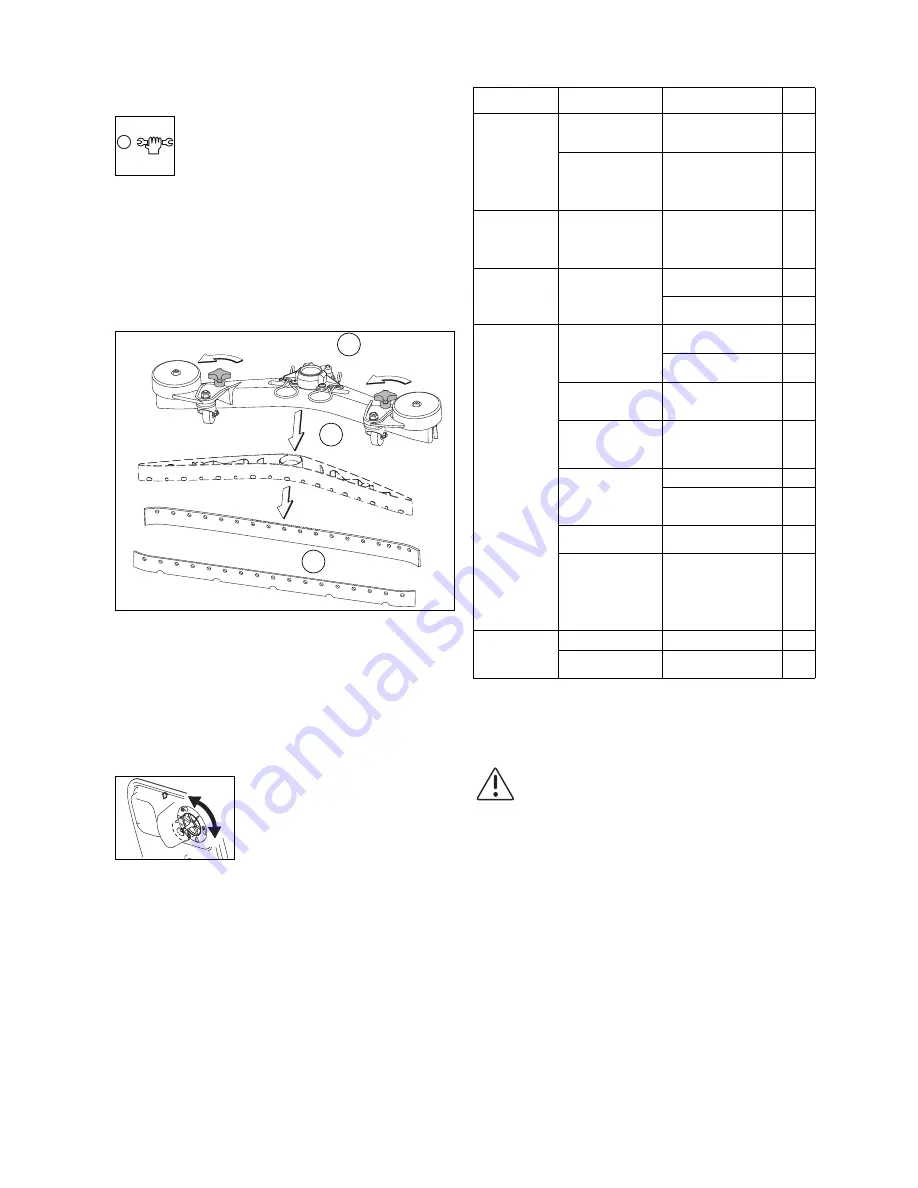

• Unscrew the star grip (1), pull the blade body (2) out of the squeegee body

and remove the blades (3).

• You can now turn or replace the blade.

• Reinsert the blade body back into the squeegee body and screw the star

grip in place again.

• Switch the machine off.

• The yellow suction filter can be easily removed

(quick-fit seal).

• Clean it under running water with the help of a

soft brush (allow to dry out completely).

• Brush the yellow suction filter with a soft brush

or remove the fluff with a cloth.

3

1

2

Malfunction

Possible causes

Troubleshooting

page

Machine does not

run

Battery disconnection

socket removed

• Insert the disconnec-

ted charger jack

36

Batteries not charged

or insufficiently char-

ged. (red display on

the battery indicator at

turn-on)

• Check

36

Brush does not

turn

The machine has

been overloaded,

causing the overcur-

rent protection to be

tripped

• Release the drive

switch and then press

it again.

36

Foam or liquid

leaking from the

machine

Float malfunction

• Turn off the suction ag-

gregate

• Check that the float is

functioning correctly.

40

Poor vacuum

performance

Floor remains

wet

Soiled solution

not picked up

The float closes the

inlet opening at the

suction unit (overfill

protection for recove-

ry tank)

• Check the recovery

tank is not full

39

• Check the functionality

of the float

40

The suction filter is

clogging due to “fluff”.

• Check whether the va-

cuum air filter is clean

and clean if necessary

39

Hose or nozzle blo-

cked, for example by

a piece of wood or

material scraps

• Remove the foreign

body

The blades do not ad-

just well to the floor

consistancy

• Clean the squeegee

• Check that the squee-

gee suspension is

functioning correctly

Worn blades

• Change/turn the bla-

des

40

Dirt sieve full (yellow)

• Remove the coarse

sieve

• Clean out the sieve by

tapping it, and rinse it

out under running wa-

ter

39

Insufficient output

of cleaning soluti-

on

Solution tank empty

• Fill the solution tank

37

Solution tank filter blo-

cked

• Clean the solution tank

filter

39

Caution:

This machine can only be lifted and transported with the use of

aids, such as a lifting platform!