27

I25

I24

I23

I22

I21

I20

I19

I18

I17

I16

I15

tr

sv

p

t

p

l

n

o

n

l

it

fr

fi

es

en

d

e

cz

cn

Drain the recovery tank / solution tank

The disposal of the soiled solution or the cleaning solution must be carried out

in accordance with the appropriate national regulations.

Proceed as follows for both tanks:

Clean the recovery tank / solution tank

Clean solution tank filter

Cleaning the tool

Removing and cleaning the squeegee

Cleaning the machine

Storage / parking of machine (machine is idle)

Store the machine with the tank cap slightly open, by:

• lifting the tank cap, unscrewing the sieve, and placing it in the hollow

provided.

Service, maintenance and care

The machine's maintenance is a pre-condition for trouble-free running and a

long life.

• Switch the machine off and pull the power supply cord out of the mains

socket.

• Remove the drainage hose from its holder.

Open the red or blue cap situated near the handle and lower the

end of the hose slowly to drain the solution out.

• Switch the machine off.

• Open the tank lid.

• Remove the coarse dirt sieve (yellow), empty and clean it.

• Remove the recovery tank and clean it under

running water.

The tank can be completely drained via the

drainage hole.

• Replace the recovery tank on the machine.

• Then thoroughly rinse out the solution tank with clean water.

• Check that the float is functioning correctly and that the suction filter (yellow)

is clean.

In case of damage or soiling of the float and suction filter, please refer to

page 28.

• After draining and cleaning, screw the red and blue caps on again, and hang

the hoses from their holders again.

Caution:

Clogged filters reduce the flow of the cleaning solution and

thereby lead to damage to the floor coating.

• Switch the machine off.

• Once the solution tank has been drained, screw

the yellow cap from the solution tank filter and

pull it away from its holder.

• Rinse the filter under running water.

If necessary, the filter should be descaled with a 10% TASKI calcacid

solution.

The filter is lower than the tank outflow. A residual amount of

solution will flow out once the filter cap has been unscrewed.

• Refit the filter and screw the yellow cap firmly into place.

• Switch the machine off and pull the power supply cord out of the mains

socket.

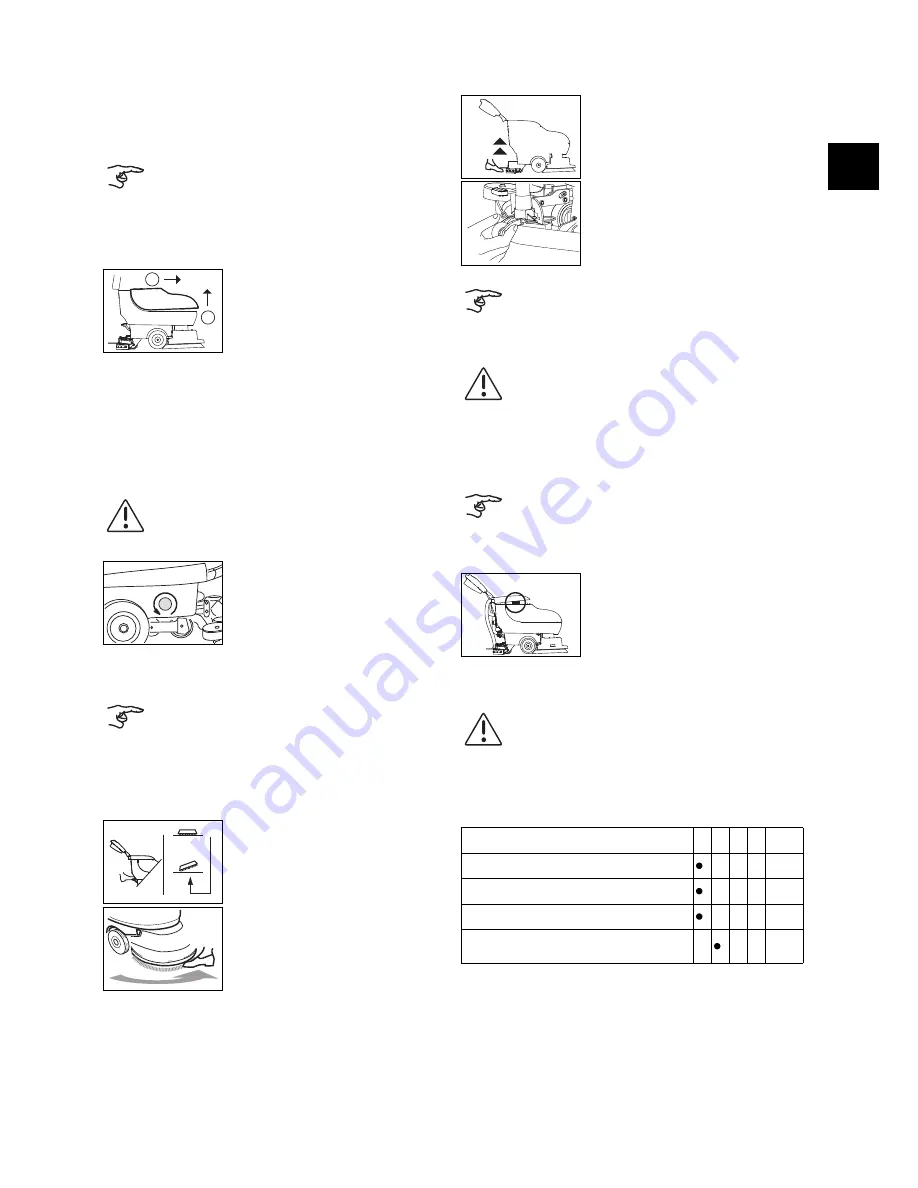

• To raise the tool, press down the foot pedal until

it latches into place.

• Turn the tool anticlockwise away from the tool

coupling using your foot.

• Clean the tool under running water.

1

2

• Switch the machine off.

• Pull the suction hose away from the squeegee support.

• Lift the squeegee by its foot.

• Press the locking springs together. The

squeegee will thereby be released and can be

removed.

• Clean the squeegee under running water using

a brush.

Optimal result can only be obtained with clean and intact blades!

Caution:

Never clean the machine with high water pressure or a water

hose.

The ingress of water into the machine might cause considerable

damage to mechanical or electrical parts.

• Wipe down the machine with a damp cloth.

We recommend disconnecting the plug from the mains socket

during storage / parking of the machine.

The coarse sieve holds the tank lid slightly open,

allowing the tank to dry out. As a result, the

formation of mould and unpleasant smells can

be reduced.

Caution:

Only TASKI branded spare parts must be used, otherwise

warranties and liabilities will be omitted!

Symbols:

= After use,

= every week,

= every month,

⊗

= Service light

Activity

⊗

page

Clean all parts marked yellow

Drain and clean the tanks

27

Clean the machine with a damp cloth

27

Clean the tank lid seal, check for cracks and

replace if necessary