2

Assembly tips - hardware

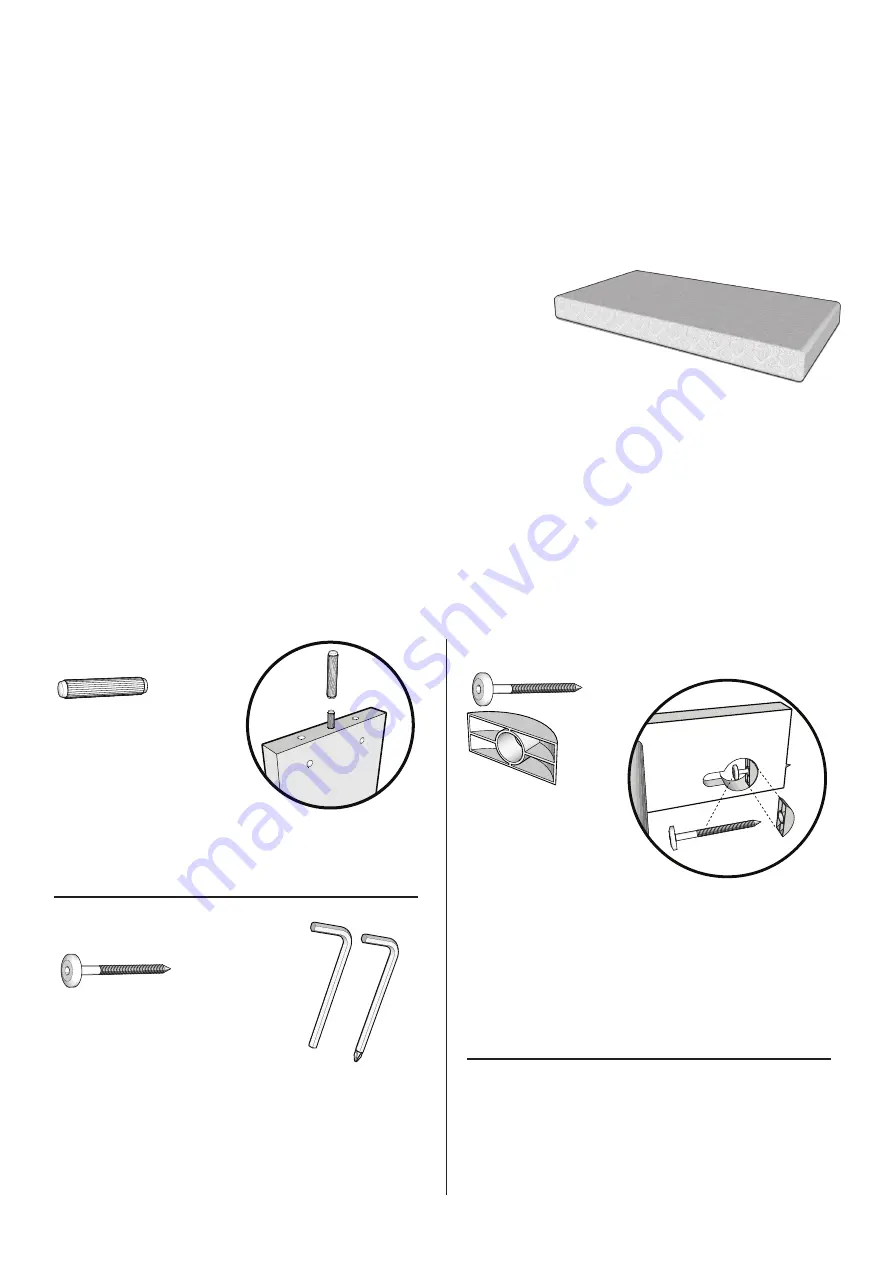

Wooden dowel pins

Connector screws and lunar washers

Screws

We recommend tightening all screws and

connectors by hand. If using a cordless driver,

set the speed to a slow setting and the clutch

to a low setting to prevent excessive tightening

that may result in damage to your furniture.

Recheck tightness

Re-tighten all connector screws (at least two

months after assembling the cot), as some

connectors may loosen as the cot settles.

Periodically check all of the connector screws,

making sure they are tight.

Gently push or tap dowel pins into place using

your thumb or a small hammer. Note, excessive

force may result in damage to the pin or furniture.

Insert the lunar washer into the locating hole, with

the curved face against the wall of the locating hole.

Insert the connector screw into the washer and push

it through until it engages with the thread of the

insert on the panel you are attaching it to. Tighten

the connector screw firmly but do not overtighten.

Warnings

Safety Consideration for your Child.

•

Follow the manufacturer’s assembly instructions in detail to ensure the safety features of the cot are not compromised.

•

ENSURE THE COT IS NOT PLACED TOO CLOSE TO HEATERS, BLINDS, CURTAINS, WINDOWS OR POWER POINTS.

•

DO NOT HANG ANYTHING NEARBY WHERE THERE IS A POTENTIAL DANGER OF THE ITEM FALLING INTO THE COT.

•

KEEP ANY MEDICATION, STRING, ELASTIC, SMALL TOYS OR SMALL ITEMS SUCH AS MONEY OUT OF REACH FROM

ANY POSITION IN THE COT. It is advisable to keep all items out of your child’s cot to prevent suffocation or strangulation.

•

TO PREVENT FALLS, THE BASE OF THE COT SHOULD BE ADJUSTED TO THE LOWEST POSITION BEFORE YOUR

CHILD CAN SIT UP.

Recommended Mattress Size.

• This cot has been manufactured for use with a mattress which measures 750

mm (wide) x 1310 mm (long) x 120 mm (maximum thickness). The width and

length are specified because it is IMPORTANT that the gaps between the

mattress and the sides and ends of the cot do not exceed 40 mm. This is to

minimise the risk of a child’s limb becoming caught in the gap. The thickness

of the mattress has been specified to ensure that the depth of the cot is

greater than 500 mm with the mattress base in the lower position to minimise

the risk of a child climbing or falling out of the cot.

Safety Consideration for Cot.

•

Re-tighten all connector bolts (at least two months after assembling the cot), as some may loosen as the cot settles. Regularly

check all of the connecting bolts, making sure they are tight.

•

Regularly check cot for weakness in timber joints and timber panels. If any weaknesses are found, report immediately to

Tasman Eco via: www.tasmaneco.com.au

•

Do not use cot if it has been damaged in any way and always use genuine Tasman Eco parts. Contact your nearest Tasman Eco

stockist or original place of purchase for spare parts

•

Report any fault with this furniture to Tasman Eco immediately. See website for details.

Summary of Contents for Verona Cot

Page 11: ...11 ...