49

2.4 Switches, gauges & indicators

Know Your Vehicle

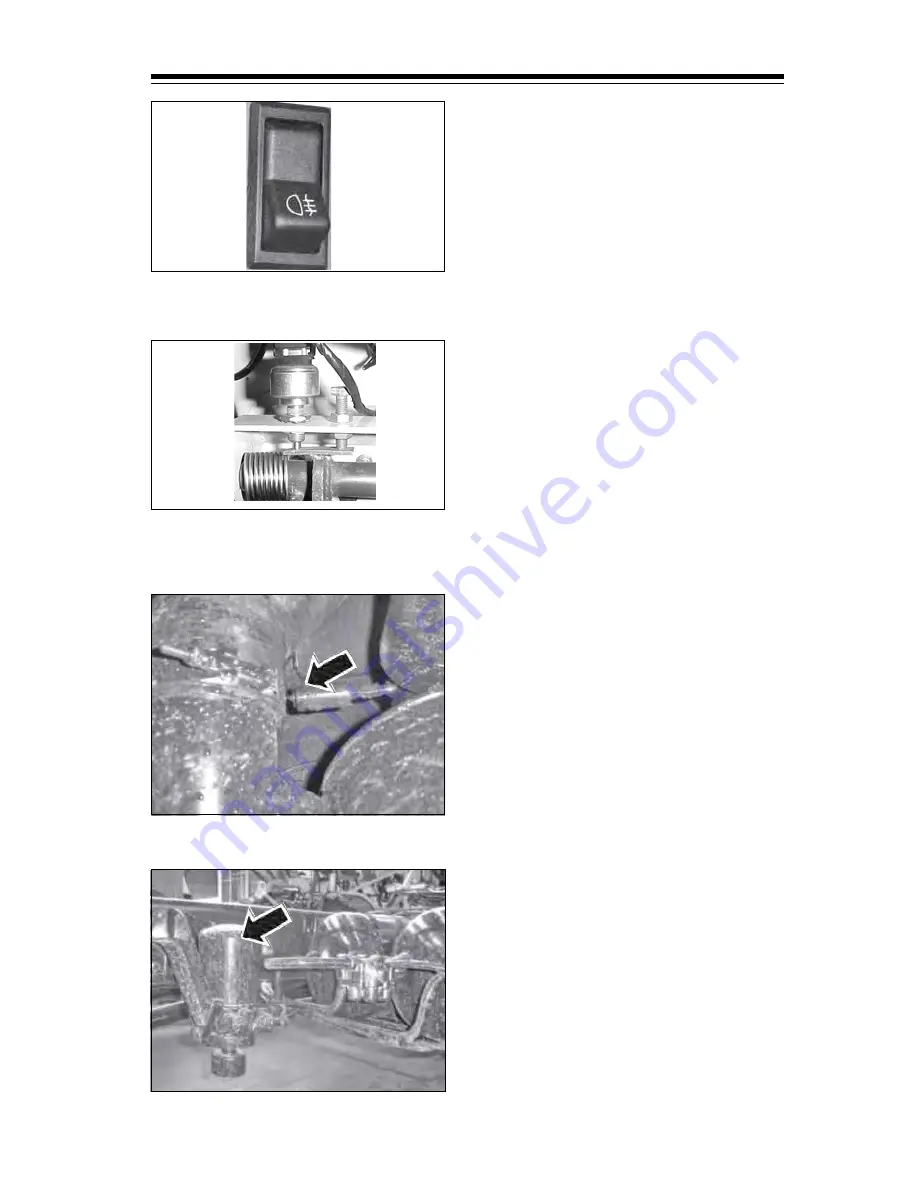

Rear fog lamp switch:

This switch is provided to switch on

Rear fog lamps. Rear fog lamps are

operative only when the park lamps

along with Head lamps (Hi beam/

Low beam) or Front fog lamps are

switched ON.

Mechanical stop light switch

A mechanical stop light switch is

mounted above brake control lever.

Whenever brake pedal is depressed

for applying brakes, stop light switch

comes into operation and lights at

rear tail lamp glow. This also activates

engine exhaust brake solenoid valve

for exhaust brake application.

Electric service indicator switch

This switch is provided on air cleaner.

Switch contact takes place only

when the filter get chocked.

Air dryer heater

This heater is a part of air dryer assy.

This heater is provided to heat the

moisture if any in the air brake lines.

This heater gets switched ON at 7

0

C

of air temperature and OFF at 29

0

C

automatically.

Rear fog lamp switch

Mechanical stop light switch

Air dryer heater

Electric service indicator switch