12

ARM200 Series

MAINTENANCE

To censure trouble-free operation and a constant safety level, an

overall check of the system should be carried out every 6 months.

A form for recording operations has been included in the “User

Guide” booklet.

ATTENTION: no-one, except for the maintenance

man, who must be a specialised technician,

must be able to use the automatic system during

maintenance.

Switch off the mains power supply to eliminate the risk of

electrocution. If the power supply must be left on for certain

operations, each control device should be checked or disabled

(remote controls, push button strips, etc.) except for the one used

by the maintenance man.

The ARM200 / ARM200BENC actuators need very little

maintenance. However, as the gate must be in good working order

for them to work properly, the operations required to keep it in

perfect condition are described below.

Routine maintenance

Each of the following operations must be carried out every 6

months for domestic use (approx. 3000 work cycles) and every 2

months for intensive use such as blocks of flats (always 3000 work

cycles).

Gate:

- lubricate and grease the hinges of the gate.

Automation system:

- check the safety devices (photocells, pneumatic edge, etc.)

work according to the manufacturer’s instructions;

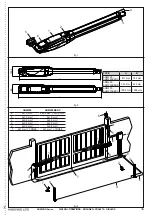

- grease (with a greaser) the worm screw from underneath the

actuator (see fig.12); TAU srl recommends using the complex

lithium soap grease produced by SYNECO.

- use a tester for lead-acid batteries to check whether the

battery is charged; if it needs replacing use an original battery

and recycle the flat one in compliance with current legislation

(alternatively, TAU srl recommends using FIAMM batteries).

N.B.: With use, a thin line of oxide may form on the

actuator stem. This is due to the materials addition

when welding the tube/stem. However, in

NO WAY

does this affect the quality or normal operation of

the gearmotor. We recommend the stem be cleaned

regularly using special products for stainless steel.

Extraordinary maintenance or breakage

If major work on electromechanical parts must be carried out, the

faulty component should be removed and repaired in the workshop

by the maker’s or other authorised technicians.

Keep all the documents concerning the system inside or near

the control unit.

SPECIAL APPLICATIONS

There is no special application other than the described use.

NOISE LEVELS

Airborne noise generated by the gearmotor in normal operating

conditions is constant and does not exceed 70 dB.

TESTING THE AUTOMATED SYSTEM

• Carefully check operating efficiency of the automated system

and of all accessories connected to it, paying special attention

to the safety devices.

• Hand the “User Guide” to the final user together with the

Maintenance register.

• Explain correct operation and use of the automated system to

the user.

• Indicate the potentially dangerous areas of the automated

system to the user.

MANUAL RELEASE

If the automated system needs to be moved manually due to a

power lack or to an actuator malfunction, proceed as follows:

1_ Cut power by means of the safety circuit breaker (even in the

event of a power lack).

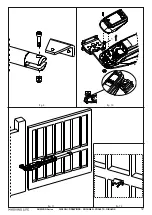

2_ Slide the protective cap, fig.16;

3_ Insert the key and turn it 90°, fig.17.

4_ As shown in fig.18, rotate the release lever upward in order to

release the actuator.

5_ Open or close the leaf manually.

Note: To hold the actuator in manual operation the

release device should be left in its current positions

and the system should be without power.

RESTORING NORMAL OPERATION

To restore normal operating conditions, proceed as follows:

1_ Lock the release lever by rotating it downward.

2_ Turn 90° the release key and remove it.

3_ Close the protection cover.

4_ Power up the system and perform some movements in order to

check the correct restoring of every function of the automated

system.

USE

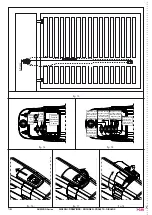

Actuators ARM225 - ARM225BENC, ARM250 - ARM250BENC

and ARM270 - ARM270BENC are designed to move gates with a

maximum length of, respectively, 3.0, 4.0 and 5.0 metres.

It is expressly

forbidden to use the device for any other

purposes or under any other circumstances other than those

mentioned.

The electronic control unit

(which must be fitted with

an electric clutch)

allows the following functions to be selected:

automatic

: a command impulse opens and shuts the gate

semiautomatic

: a command impulse opens or shuts the gate.

In the event of a power failure, the gate may be moved manually by

activating the “

manual release

” device. Mod. ARM200BENC can

be powered by a buffer battery and is able to perform at least 15

complete cycles (open and close) on its own.

This is an electrically powered automatic device and should

therefore be used with care. In particular:

• do not touch with wet hands and/or wet or bare feet;

• disconnect the power supply before opening the control box

and/or the actuator;

• do not pull the plug out by its cable;

• do not touch the motor unless you are certain it is cool;

• only operate the gate when it is completely visible;

• do not approach the gate while it is moving;

• do not allow children or animals to play near the gate;

• do not allow children or disabled people to use the remote

control or other operating devices;

• carry out routine maintenance;

• in the case of a fault, disconnect the power supply and only

move the gate if it is possible and safe to do so. Do not touch

the gate and call in an authorised technician.

ENGLISH