LUXE

14

When adjustment has been completed, carry out the saving

procedure onto the control card (see K206MA instructions),

checking the correct position of the bar from the second auto-

matic operation (the first is used by the control unit to accept

the new stops); repeat the procedure as required.

When all the mechanical and electronic installation is complete, fix

the cabinet cover, reposition the door and lock.

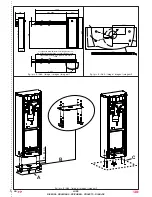

3.9_ Electrical connections

All devices, supply included, must be installed up to standard and

in compliance with the regulations in force. Separate the power

cables from the control cables, above all if the paths are long (over

50m). As to the cable section (aerial excluded), TAU recommends:

supply 1.5mm², other cables 0.5mm², follow anyway IEC 364 and

the installation regulations in force in your country. To access the

control card, remove the cabinet cover (1 pic. # 9) after removing

the locking screws and washers. It is then possible to reach the

connections.

Note: internal connections are already made and tested. The

supply, external photocell, LEDs and any remote controls

must be connected and the card must be programmed.

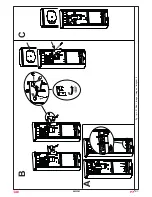

3.10_ Last operations

When the correct operation of all devices controlling the bar has

been checked, make sure everything is reset before handing over

to the users.

Place signs warning people about the barrier where they can be

easily read.

4_

USE

The barrier has been exclusively designed to limit the flow of vehi

-

cles and/or persons in restricted entrances by means of a bar. In

the event of blackout, functioning can be guaranteed by means of

an optional 12V dry battery.

Furthermore, it also comprises electrical equipment and therefore

must be approached and used with caution and foresight. In par

-

ticular we recommend:

• not to touch the equipment with wet hands and/or bare or wet

feet;

• not to perform the automatic or semiautomatic function in the

presence of known or suspected malfunctions;

• not to pull the cable to disconnect the equipment;

• not to let children, or those unable, use the cabinet keys or

controls (including remote controls) even if only to play with;

• not to operate the barrier until it is completely in view;

• not to enter within the operating range while it is moving, wait

for it to stop;

• not to rest against the bar or cabinet for any reason, even when

the barrier is inactive and do not remain within the operating

range of the barrier;

• not to let children or animal play within the operating range of

the barrier;

• not to use the barrier for purposes (e.g. lifting of weights or

persons) other than those foreseen. The manufacture holds no

responsibility what so ever for damages caused by the said ac

-

tions;

• to perform periodic maintenance by specialised personnel;

• if there is a fault, turn off the power supply. Use the manual

manoeuvre only if safe. Do not attempt to resolve the problem

yourself, contact a qualified technician of the manufacturer or

authorised by the manufacturer. In any case, make sure that

the spare parts are original so that the safety of the barrier is

not compromised.

5_ MAINTENANCE

To be performed by specialised personnel only after having turned

off the power supply.

After every 100,000 manoeuvres, check:

- the greasing of the springs;

-

the balance of the bar (see chapter “Bar fixing, spring fitting

and bar balancing”)

;

- the efficiency of the force;

-

the integrity of the battery, if present;

- The efficiency of the protection and safety devices;

- the wear on the mechanical stops and the adjustment of the

limit switches (see chapter “Limit switch adjustment”).

The above mentioned maintenance is vital in order that the

product functions correctly throughout time.

In general

It must be impossible for third parties to operate the barrier during

maintenance; therefore turn off the mains power supply (and bat

-

tery if present).

• Release the bar first in order to facilitate the operation.

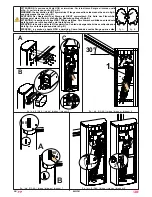

Greasing

1_ open the cabinet door;

2_ lubricate with grease both the screw eye of the balancing spring

(1 pic. 10) and the ball joint on the balancing lever (3 pic. 10);

3_ grease the contact points between the cam of the manual re

-

lease and the release lever (2 pic. # 10);

4_ keep away from possible moving gears or mechanical parts.

FREQUENCY: every 100,000 manoeuvres or 6 months,

fail-

ing which the guarantee lapses

.

N.B it is highly recommended to use high resistance grease

based on calcium soap.

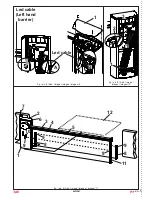

Bar balancing

Check the bar is balanced correctly repeating the operations de

-

scribed in “Bar fixing, spring fitting and bar balancing”. This op

-

eration is fundamental for the correct functioning and duration of

the barrier. If necessary, increase the preloading of the springs in

order to compensate for its wear. See the subsequent paragraph

“Extraordinary maintenance and repairs” in the event the springs

need to be changed.

FREQUENCY: every 100.000 manoeuvres or 6 months,

failing

which the guarantee lapses

.

Control of the force limitation efficiency

Check the correspondence between the true operation and the op

-

eration established during installation.

FREQUENCY: every 100.000 manoeuvres or 6 months,

failing

which the guarantee lapses

.

Control of the 12V dc battery

Check the charge level of the battery by means of a tester. If re

-

placement is necessary, substitute the flat battery with an original

and do not dispose of it in the environment.

FREQUENCY: every 100.000 manoeuvres or 6 months,

failing

which the guarantee lapses

.

Control of the remaining protection and safety devices

Photocells: they can trigger both in opening as well as in closing;

check the dip-switch programming. Clean the outer casing.

Check that the following specifications are respected:

• The flashing light is working and visible;

• The adhesive danger sign on the door is well attached and vis

-

ible;

• The adhesive danger sign on the back of the barrier is well

attached and visible. If these signs do not correspond to the

stated conditions, restore their original effectiveness or, if this

is impossible, replace them.

FREQUENCY: every 6 months,

failing which the guarantee

lapses

.

6_ EXTRAORDINARY MAINTENANCE AND REPAIRS

ATTENTION: ON COMPLETION OF THE FIRST 2000 MANOEU-

VRES, THE ROD BALANCING PROCEDURE MUST BE CAR-

RIED OUT AGAIN.

If a complicated repair or replacement of electromechanical parts

is necessary, the unit in question (control unit, gearmotor unit)

should be removed in order for the repair to be carried out by the

manufacturer or by authorised technicians. Otherwise, the safety

and reliability of the barrier may be reduced (such as the guarantee

for example).

If the barrier is used in a saline environment or an en-

vironment that is highly contaminated by corrosive

chemical reactants, the frequency of the maintenance

controls must be increased due to the increased envi-

ronmental deterioration; In this case the external metal

cabinet should also be inspected.

ENGLISH