Turbomachinery Package Specification

Taurus

60 Compressor Set and Mechanical Drive

7.3

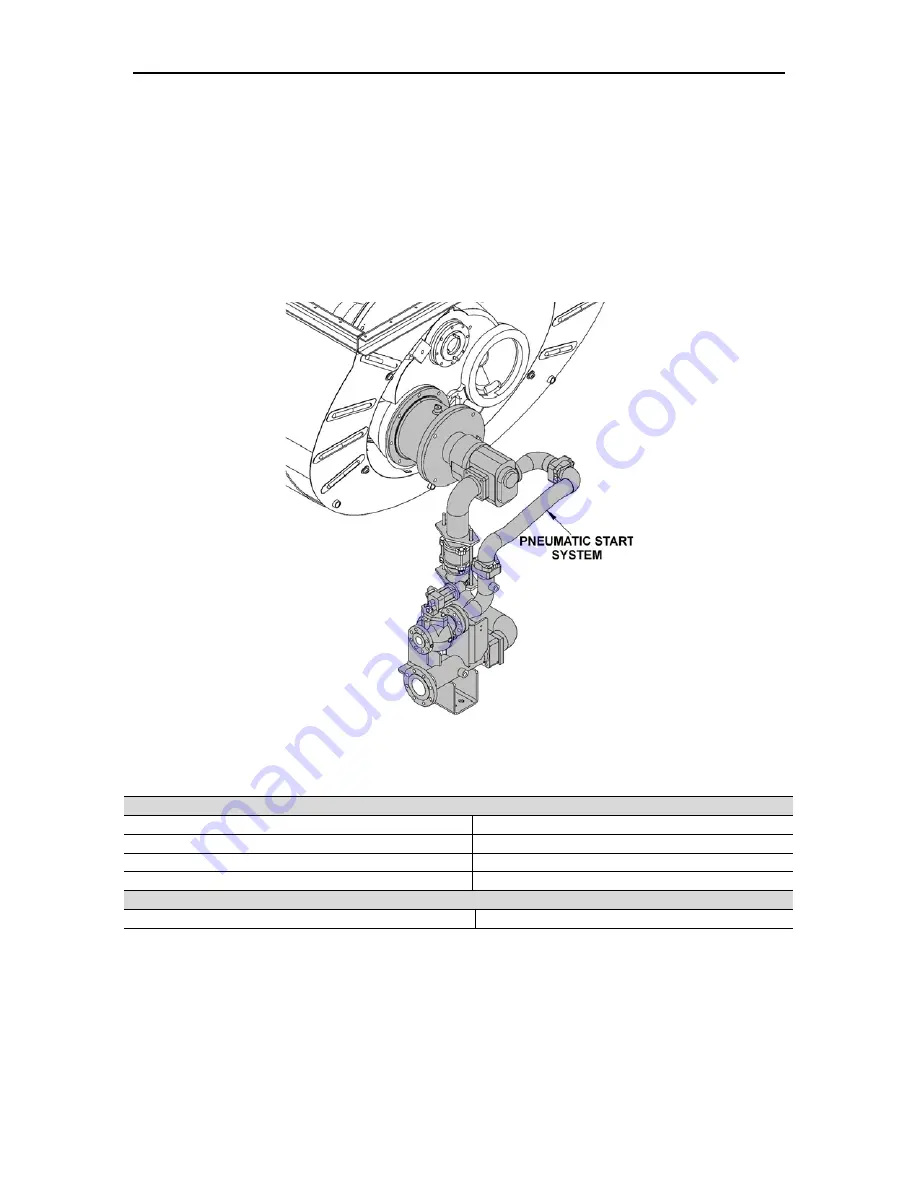

Pneumatic Start System (Optional)

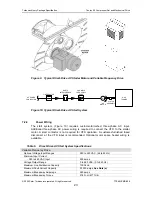

The pneumatic start system, (Figure 11) can use either process gas or compressed air as

a power source. The standard system consists of a strainer, shutoff valve, pneumatic

starter motor, and associated stainless steel piping and manifolds. The pneumatic starter

motor is mounted directly on the gas turbine accessory drive gearbox and transmits

starting power to the gas turbine via an overrunning clutch and shaft. When the gas

turbine reaches starter dropout speed, the start system is de-energized and the clutch

overruns.

Figure 11. Typical Pneumatic Start System

Table 7.

Pneumatic Start System Specifications

Pneumatic Start Motor

Fluid

Air or Natural Gas See Note (a)

Pressure

1379 to 2758 kPag (200 to 400 psig)

Flow

113 nm3/min (4000 SCFM)

1 Minute Exhaust Purge Consumption

119 nm

3

(4200 SCF)

Solar’s Applicable Engineering Specifications

ES 2201

Auxiliary Service Air

Notes:

(a)

The particle size in the air stream should not exceed 10

μ

. Since it is impractical to remove

100% of all particles larger than 10

μ

, this is defined as ß10 > 100, or 99% efficient. Oil or

hydrocarbon content should not exceed 1 ppm. The dew point at line pressure shall be at

least 6

°

C (10

°

F) below the minimum temperature to which any part of the air system is

exposed or between -29

°

C and 93

°

C (-20

°

F and 200

°

F). Air should be free of all corrosive

contaminants, hazardous gases, flammables, and toxics.

© 2009 Solar Turbines Incorporated. All rights reserved.

TPS60CSMD/309

25