m

6. Before starting the machine

•

Before you connect the appliance to the

mains supply make sure that the data on the

rating plate are identical to the mains data.

•

Always pull the power plug before making

adjustments to the equipment

•

Unpack the saw and check it for damage

which may have occurred in transit.

•

The machine has to be set up where it can

stand firmly, e.g. on a work bench, or it must

be bolted to a strong base.

•

All covers and safety devices have to be

properly fitted before the machine is switched

on.

•

It must be possible for the blade to run freely.

•

When working with wood that has been

processed before, watch out for foreign

bodies such as nails or screws, etc.

•

Before you actuate the On/Off switch, make

sure that the saw blade is correctly fitted and

that the machine’s moving parts run smoothly.

7. Installation

Caution: Pull out the power plug before

carrying out any maintenance, alteration or

assembly work on the table circular saw.

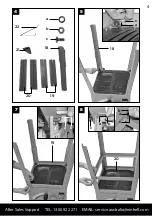

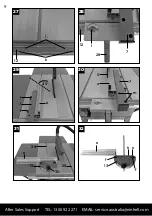

7.1 Fitting the base frame (Fig. 4-9)

•

Turn the bench circular saw around and lay it

on the floor

•

Screw the four legs (18) loosely to the saw

with the short hex screws (c) and washers (a).

•

The legs (18) with the two holes which lie one

above the other on the underside must be

mounted at the rear of the machine, so that

the holes are facing the rear. (Fig. 5)

•

Now fasten the longitudinal and cross struts

(19), as well as the middle struts (20) loosely

with the hex screw (c), washers (a) and nuts

(b), to the legs (Figs. 6, 7).

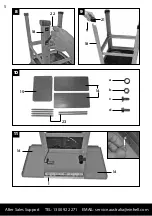

•

Only screw the hex screws (c) and nuts (b)

loosely. Important: The longer struts must be

used on the sides.

•

Screw the stability bar (22) to the holes on

the rear legs (18) with 2 long hex screws

(c), washers (a), locking ring and nuts each.

(Figure 8)

•

Caution: Both stability bars must be attached

to the rear side of the machine.

•

Now attach the rubber feet (21) to the legs

(18). (Figure 9)

•

Then screw all of the screws and nuts to the

base frame.

18

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

5. Technical data

Motor

240 V ~ 50Hz

Power rating P

S6 40% 1700 W

Idle speed n

0

6,500 min

-1

Carbide saw blade

Ø 250 x Ø 30 x 2.4 mm

Number of teeth

24T (Coarse Cut - Fitted)

48T (Fine Cut - Spare)

Bench size

610 x 445 mm

Table width extension, left/right

608 x 250 mm

Table length extension, rear

435 x 320 mm

Cutting height max.

72 mm / 90°

54 mm / 45°

Height adjustment

infinite 0 - 72 mm

Tilting saw blade

infinite 0° - 45°

Dust extraction connector

Ø 36 mm

Net Weight

28.2 kg

Operating mode S6: Continuous operation

with idling (cycle time 10 minutes.)

To prevent unnecessary heating of the motor,

the bench circular saw may only be used in the

following ways:

After operation for 4 minutes (S 6 = 40%) with

normal permitted workload, a break of 6 minutes

must follow, in order to let the circular saw idle

and cool.

Noise emission values

Idle speed

sound pressure level L

pA

101 dB(A)

sound power level L

WA

110 dB(A)

The quoted values are emission values and not

necessarily reliable workplace values. Although

there is a correlation between emission and

immission levels it is impossible to draw any

certain conclusions as to the need for additional

precautions. Factors with a potential influence

on the actual immission level at the workplace

include the duration of impact, the type of room,

and other sources of noise etc., e.g. the number

of machines and other neighbouring operations.

With this information the user should at least be

able to make a better assessment of the dangers

and risks involved.