m

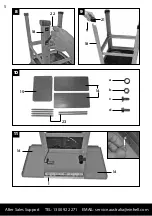

7.2 Attaching the table length and width

extensions (Fig. 10-14)

•

Loosely attach the table width and length

extensions (14/15) to the saw bench (1) with

the hex screws (c), washers (a) and nuts (b).

(Figure 12-13).

•

Screw the supports (23) loosely to the housing

of the bench saw and to the table width/

length extensions. (Short supports for width

extension, long supports for length extension)

(Fig 13-14).

•

Adjust the table width and length according to

the saw bench (1).

•

Finally, tighten all screws.

•

Turn the saw and base frame around and set it

on the floor.

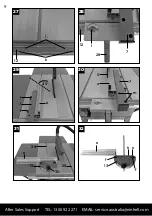

7.3 Assembling/disassembling the saw

blade guard (Fig. 2, 15-16)

•

Set the saw blade guard (2) with screw (24)

from above onto the splitter (4), so that the

screw sits firmly in the oval hole (25).

•

Do not tighten the screw (24) too much; the

saw blade must be able to move freely.

•

Attach the extractor hose (3) to the extractor

adapter (16) and to the extraction port of the

saw blade guard (2) and screw them to the

extractor adapter with the safety clamp (16).

•

Connect a suitable chip extraction system to

the extractor adapter (16).

•

To dismantle, proceed in reverse order.

Caution: Before starting to saw, the saw

blade guard (2) must be lowered onto to the

workpiece.

7.4 Replacing the table insert (Fig. 17-18)

•

If the table insert is worn or damaged, it

should be replaced, otherwise risk of injury is

increased.

•

Take off the saw blade guard (2) (see 7.3)

•

Remove the 2 countersunk screws (26)

•

Remove the worn table inserts (6)

•

Assembly of the new table inserts is to be

carried out in reverse order.

7.5 Adjusting the splitter (Fig. 19-20)

•

Caution: Pull out the power plug.

•

Set the saw blade (5) to max. cutting depth.

•

Adjust and lock the cutting depth into the 0°

position (see Fig. 8.2).

•

Disassemble the saw blade guard (see 7.3)

•

Remove the table inserts (6) (see 7.4)

•

Loosen the fixing screws (27).

7.5.1 Setting for maximum cuts

•

Push up the splitter (4) until the gap between

the saw table (1) and the upper edge of the

splitter (4) is at 10cm.

•

The distance between saw blade (5) and

splitter (4) should be a maximum of 5mm. (Fig.

20)

•

Re-tighten the screws (27) and assemble the

table inserts (6) (see 7.4).

19

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

7.6 Assembly/Changing the saw blade

(Fig. 21)

•

Caution: Pull out the power plug first.

•

Detach the saw blade guard (2) (see Fig. 7.3).

•

Remove the table inserts by loosening the 2

countersunk screws (see 7.4)

•

Loosen the nut (

Caution!

Turn the nut in the

direction in which the saw blade rotates) by

using a wrench (24mm) on the nut and another

wrench (10mm) on the motor shaft to apply

counter-pressure.

•

Remove the outer flange and withdraw the old

saw blade diagonally from the inner flange.

•

Clean the blade flange thoroughly before

fitting the new blade.

•

Mount and fasten the new saw blade in reverse

order.

•

Caution: Note the running direction. The

cutting angle of the teeth must point in

running direction, i.e. forwards (see the arrow

on the blade guard).

•

Refit and set the table insert (6) and the saw

blade guard (2) (see 8.4, 8.5)

•

Check to make sure that all safety devices

are properly mounted and in good working

condition before you begin working with the

saw again.

8. Operation

8.1 ON/OFF Switch (Fig. 22/pos. 11)

•

The saw can be switched on by pressing the

green button “I”. Before starting to saw, wait

until the saw blade has reached its maximum

rotation speed.

•

In order to switch the saw off again, the red

button “0” must be pressed.

8.2 Cutting depth (Fig. 22)

•

By turning the hand crank (8), the saw blade

(5) can be adjusted to the desired cutting

depth.

Anticlockwise direction:

Larger cutting depth

Clockwise direction:

Smaller cutting depth

8.3 Setting the angle (Fig. 22)

•

Loosen the locking grip (9)

•

Set the desired angle on the scale by turning

the handle.

•

Lock the locking grip to the desired angularity.

8.4 Parallel stop

8.4.1. Stop height (Fig. 23-26)

•

The stop rail (e) of the parallel stop (7) has two

different guide faces.

•

According to the thickness of the material to

be cut, the stop rail must be used according

to Fig. 25 for thick material (over 25mm

workpiece thickness), and according to Fig.

26 for thin material (under 25mm workpiece

thickness.