ROW

X

32

5.3

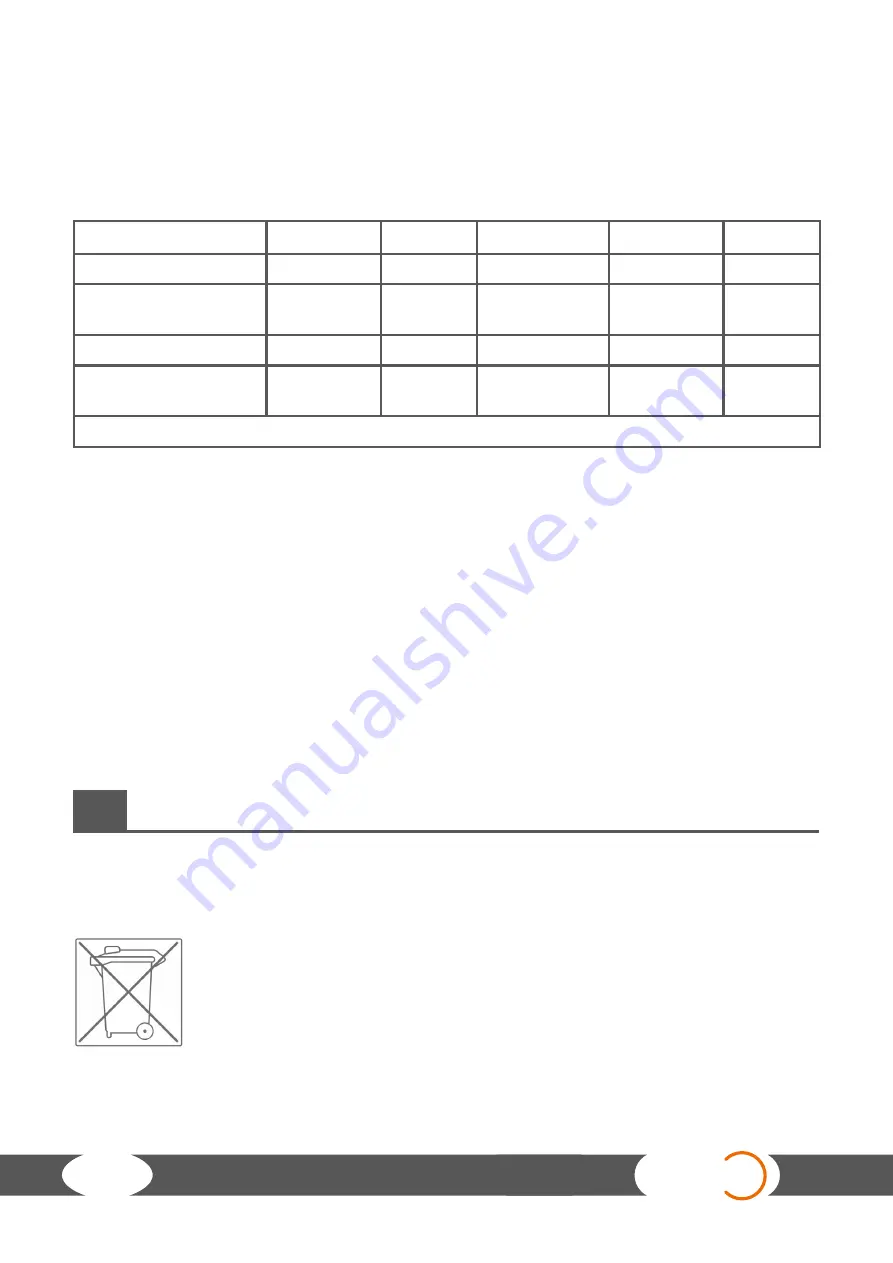

Maintenance and Inspection Calendar

To avoid damage from body sweat, the equipment must be cleaned with a damp towel (no solvents!)

after each training session.

The following routine tasks must be performed at the specified intervals:

Part

Weekly

Monthly

Quarterly

Half-yearly

Yearly

Display console

C

I

Lubrication of the

moving parts

I

Plastic covers

C

I

Screws and cable

connections

I

Legend: C = clean; I = inspect

Lubrication of the chain

Lubricate the chain at least every six months or even better after approx. 50 operating hours. Use a

non-fraying cloth as well as 20W motor or multi-purpose oil. Drop approx. one teaspoon of the oil on

the cloth. Then pull out carefully the chain on the handle to the fence. Wipe along the chain with the

cloth several times. Then remove the remaining oil with a dry cloth.

Cleaning the rail

Before the training, wipe the rail with a damped cloth to remove any dust.

6

DISPOSAL

At the end of its operational life, this equipment cannot be disposed of in normal household waste.

Instead, it must be disposed of via an electricals recycling centre. Further information can be

obtained from your local authority‘s recycling service.

The materials can be recycled as per their symbols. Through the reuse, recycling

of materials or other forms of recovery of old equipment, you make an important

contribution to the protection of the environment.

Summary of Contents for ROW-X

Page 1: ...TF TFROWX 01 04 Assembly and Operating Instructions Art No TF ROW X Rowing machine ROW X ...

Page 2: ...ROW X 2 ...

Page 42: ...ROW X 42 Notes ...

Page 43: ...43 ...

Page 44: ...Rowing machine ROW X ...