34

33

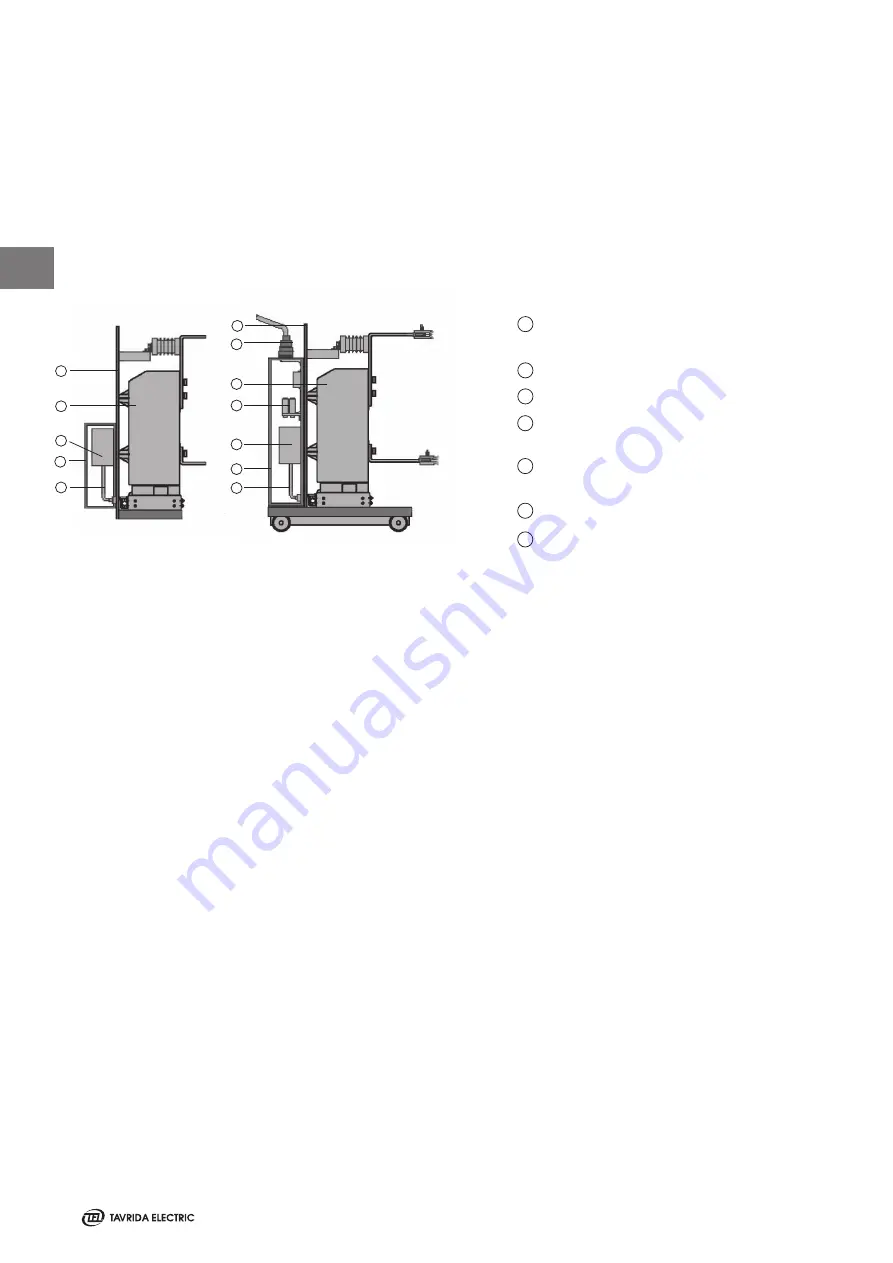

Figure 50

Stationary type installation

3

1

2

5

4

Figure 51

Draw out type installation

6

2

7

3

4

5

1

Steel plate

> 1 mm thick

ISM

CM

Closed steel box

> 1 mm thick

Shielded cable

Secondary

circuit plug

Secondary

components

1

2

3

4

5

6

7

Ins tallation of the CM

The installation of the CM is carried out according to the panel design either on the draw out unit or in the low

voltage compartment of the switchboard. It must be separated from the high voltage compartment. The CM shall

be installed in an grounded mild steel box with a thickness of not less than 1 mm.

The CM can operate in any mounting position. Care must be taken for good access and visibility of the terminals,

LEDs and setting elements for operation and maintenance. Basically the ambient conditions as described in chapter

“Regulations and ambient conditions” (page 73) shall apply.

Summary of Contents for ISM Shell_2 Series

Page 2: ...2...

Page 6: ...6 1 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 7: ...7 Introduction 1...

Page 12: ...12 1 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 13: ...13 Receiving Handling and Storage 2...

Page 19: ...19 Ins tallation 3...

Page 36: ...36 3 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 37: ...37 Switching and Control Functions 4...

Page 41: ...41 Commiss ioning Maintenance 5...

Page 44: ...44 5 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 45: ...45 Signalling 6...

Page 49: ...49 Special Applications Fast Switching 6...

Page 53: ...53 Product Line 7...

Page 55: ...55 Dimens ions and Weights 8...

Page 61: ...61 8 Mating part with interlocking lever Interlockingshaftwithmountedinterlockinglever...

Page 62: ...62 Circuit Diagrams 9...

Page 63: ...63 ISM15_Shell_2 with CM_1501_01 9...

Page 64: ...64 ISM15_Shell_2 with CM_16_1 9...

Page 65: ...65 9 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 66: ...66 Technical Data 10...

Page 71: ...71 10 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 72: ...72 Regulations and Ambient Conditions 11...

Page 74: ...74 Legal Information 12...

Page 77: ...77 12 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 79: ...79 Date 12...

Page 80: ...80 Date 12...

Page 81: ...81 Date 12...