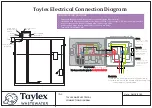

1370 mm

2900 mm

1530 mm

1270 mm

3000 mm

2425 mm

100 mm

2900 mm

100 mm

355 mm

ABS CONCRETE TALL 600

Excavation Instructions

Tank Total Mass = 8.00 Tonne

32mm

Irrigation

Outlet

Lifting

Hole

20mm

Electrical

Inlet

100mm

Inlet

Lifting

Hole

Lifting

Hole

TAYLEX ABS

EXCAVATION INSTRUCTIONS

1. Dig hole 3000mm square & 2900mm

Deep

2. Ensure drainage has a 1/60 fall to the

inlet of ABS. Risers are available if the

tank needs to be installed deeper in the

ground to maintain fall

3. Cover base of hole with 100mm of

5mm to 7mm drainage gravel or sand

4. Ensure bottom of hole is level

5. Backfill with soil from Excavation in no

more than 500mm equally distributed

layers around the tank. Avoid backfilling

with rocks over 300mm.

6. To prevent flotation, fill the ABS with

5,000lt of water immediately through

hole above the aeration chamber

(see diagram below)

7. Ensure top of gravel/sand is 1530mm

to bottom of inlet

100mm of

5mm-7mm

drainage

gravel or sand

Please Note:

5,000lt of water

to be placed in

this chamber to

prevent flotation

Top of tank to be a minimum

of 100mm above landscaped ground level

Lifting

Holes

100mm

Inlet

Lifting

Holes

ELECTRICIAN

Connect through conduit on side of ABS.

Run wire (min 2.5mm) through the flexible

conduit provided and up into the switch located

in the blower box.

Active - Neutral - Earth.

TRUCK ACCESS

Unloading of ABS via the back of the truck

NOT SIDE. Ensure BACK of truck has clear

level 6m wide access to the edge of the hole.

REACH OF CRANE/ CRANE TRUCK

To be determined by your crane/ crane truck

operator.

Top of tank to be a minimum

of 100mm above landscaped ground level

Page

14

of 16