Motor Service

Motor

Page 2

Enclosed Motors (GE, no cooling fan)

General Electric Motors

NOTE: Some motors may not have the brush

inspection holes. In this case, the motor must

be disassembled to inspect the brushes. For

future inspections, holes msy be drilled into

the motor housing after it has been

disassembled.

6. Insert a 0.035” diameter wire through the brush

inspection hole above each brush until it contacts

the top of the brush.

7. Mark the wire to indicate how far it was inserted

into the motor housing.

8. Remove the wire and measure how far into the

motor the wire was inserted.

9. If any one wire insertion length exceeds the length

specified in

Service Limits

, then all four brushes

should be replaced. Refer to

Replacing the

Brushes

section for information regarding

replacing the motor brushes.

10. Reconnect the main positive and negative cables

at the batteries.

11. Remove the blocks from behind the wheels,

release the park brake and test drive.

INSPECTING THE MOTOR BRUSHES

1. Make sure the key-switch is in the “OFF”

position, then remove the key.

2. Place the forward-reverse switch in the

center “OFF” position.

3. Set the park brake.

4. Place blocks under the front wheels to

prevent vehicle movement.

5. Disconnect the main positive and

negative cables at the batteries.

Typical motor with cooling fan indicated by

the arrow

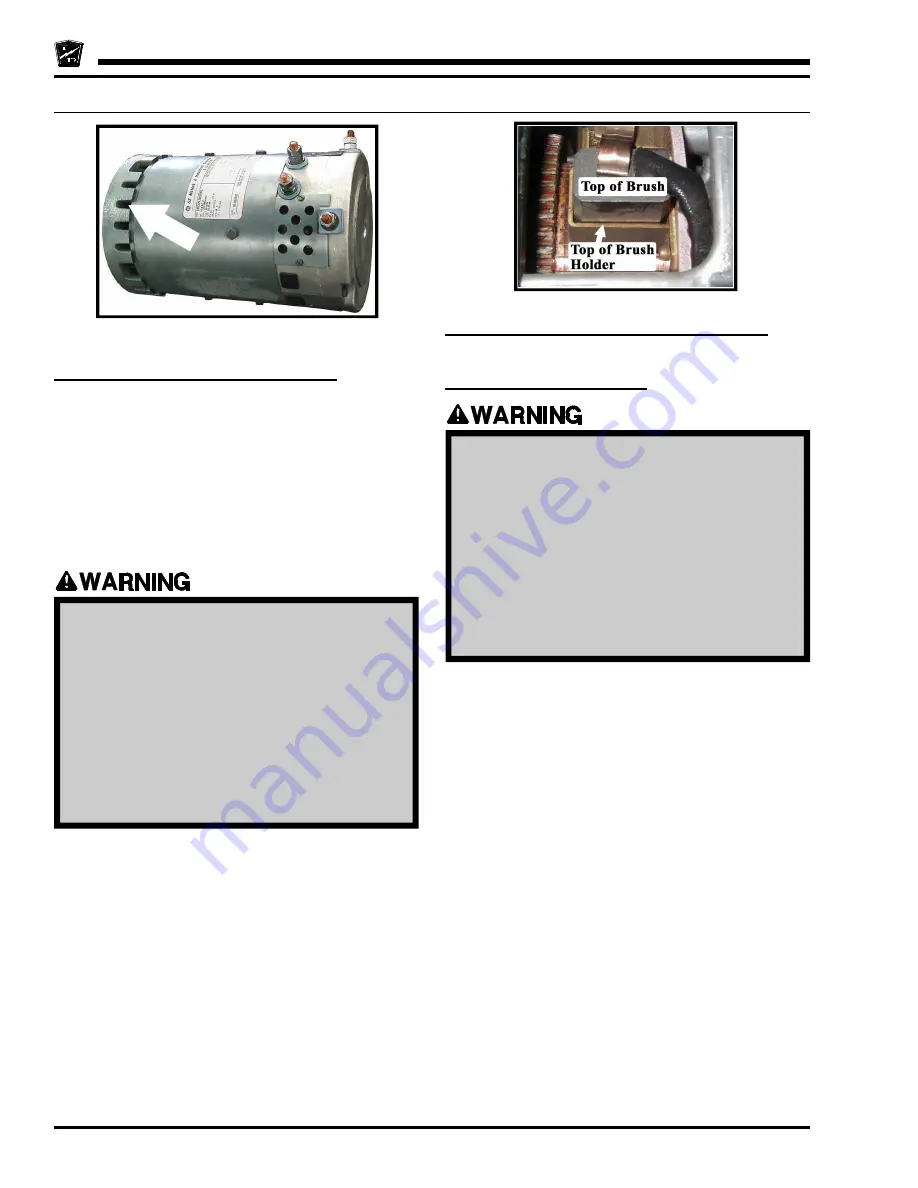

Typical brush and brush holder

Motors with internal cooling fans

NOTE: There are four brushes in the motor. The

brushes will not wear at the same rate. It is

recommended that all four brushes are

inspected at the same time.

NOTE: In some vehicle configurations it may not be

possible to inspect all four brushes while the

motor is in the vehicle. Refer to

Transmission Service

section for

information on removing the motor.

6. Look through the brush cover and compare the

top of the brush to the top of the brush holder. If it

is even with or below the top of the brush holder

then the brushes should be removed and

measured. Refer to

Replacing the Brushes

section for information regarding removing the

motor brushes.

7. If any one brush is less than or equal to the service

limit specified in

Service Limits

, then all four

brushes should be replaced.

8. Reconnect the main positive and negative cables

at the batteries.

9. Remove the blocks from behind the wheels,

release the park brake and test drive.

1. Make sure the key-switch is in the “OFF”

position, then remove the key.

2. Place the forward-reverse switch in the

center “OFF” position.

3. Set the park brake.

4. Place blocks under the front wheels to

prevent vehicle movement.

5. Disconnect the main positive and

negative cables at the batteries.

Summary of Contents for B 1-50

Page 2: ......

Page 6: ...TAYLOR DUNN ...

Page 14: ...Model B 1 00 ...

Page 30: ...TAYLOR DUNN ...

Page 36: ...TAYLOR DUNN ...

Page 52: ...TAYLOR DUNN ...

Page 66: ...Maintenance Service and Repair Steering Page 14 Exploded View of Steering Gear ...

Page 90: ...TAYLOR DUNN ...

Page 124: ...TAYLOR DUNN ...

Page 130: ...TAYLOR DUNN ...

Page 161: ...Wire Diagrams ...

Page 194: ...Illustrated Parts PARTS PAGE 10 Front Suspension 4 3 2 1 5 10 6 8 9 7 11 12 ...

Page 202: ...Illustrated Parts PARTS PAGE 18 Motor 2 3 5 6 4 7 8 1 9 10 Armature 9 ...

Page 206: ...Illustrated Parts PARTS PAGE 22 Wheels and Tires Ref wheel hub 1 2 5 assembly 4 3 6 7 8 9 ...

Page 208: ...Illustrated Parts PARTS PAGE 24 Instrument Panel dash ...

Page 217: ...Illustrated Parts PARTS PAGE 33 This page intentionaly left blank ...

Page 220: ...Illustrated Parts PARTS PAGE 36 Seat Cushions Deck and Lights B 1 50 ...

Page 222: ...Illustrated Parts PARTS PAGE 38 Seat Cushions Deck and Lights MX 1600 ...

Page 224: ...Illustrated Parts PARTS PAGE 40 Decals B 1 50 VIEW FROM INSIDE OF COWL 1 2 3 4 5 6 7 8 9 ...

Page 230: ...Illustrated Parts PARTS PAGE 46 Stake Sides B 1 50 1 2 3 4 5 6 7 8 ...