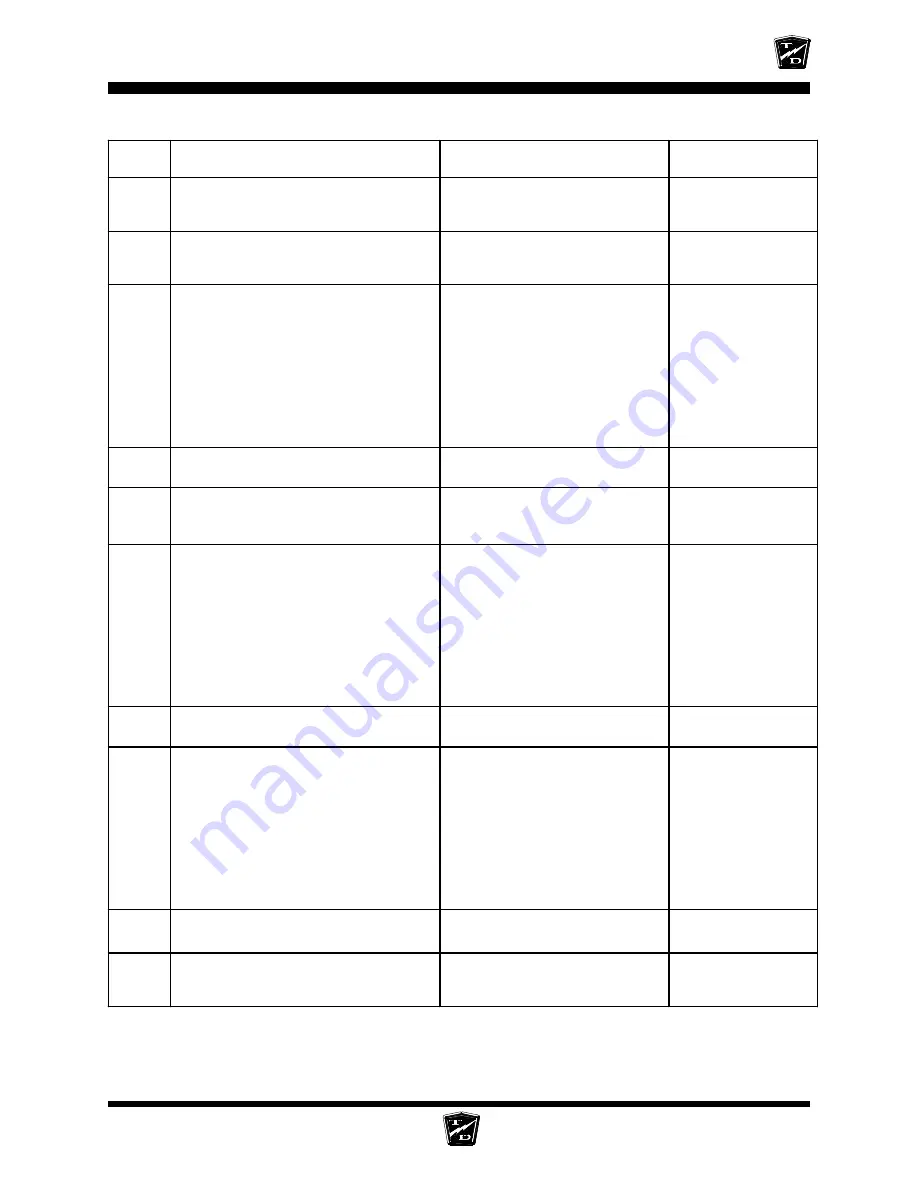

Electrical Troubleshooting

Troubleshooting

Page 5

Code

Handset Display

Effect of fault

Possible Cause

Note

44

Brake Wiper Low

Full brake.

1.

See note, voltage too low on pin-17

Not used – If fault occurs

then check controller

connector for

contamination

45

Pot Low Overcurrent

Shutdown throttle;

Full brake.

1.

Current into pin-18 exceeded 0.010A

Not used – If fault occurs

then check controller

connector for

contamination.

46

EEPROM Failure

Shutdown main contactor;

Shutdown motor;

Shutdown EM bake;

Shutdown Throttle;

Shutdown interlock

Shutdown Driver 1;

Shutdown Driver 2;

Shutdown Driver 3

Shutdown Driver 4;

Shutdown PD;

Full brake.

1.

Controller parameters corrupted.

Controller must be

returned to factory for

reprogramming.

47

HPD/Sequencing Fault

Shutdown throttle.

1.

Startup switches not operated in the

correct order.

2.

Faulty wiring or switches.

Refer to operator section

for correct startup

sequence.

49

Parameter Change Fault

Shutdown main contactor;

Shutdown motor;

Shutdown EM bake.

1.

May occur when adjusting parameters.

Cycle key switch to clear

fault.

68

VCL Runtime Error

Shutdown main contactor;

Shutdown motor;

Shutdown EM bake;

Shutdown Throttle;

Shutdown interlock

Shutdown Driver 1;

Shutdown Driver 2;

Shutdown Driver 3

Shutdown Driver 4;

Shutdown PD;

Full brake.

1.

Controller parameters corrupted.

Controller must be

returned to factory for

reprogramming.

69

External Supply Out of Range

None.

1.

Faulty wiring.

2.

Faulty motor encoder.

3.

Faulty dash display.

Excessive combined

current into pin-26 and

pin-25.

71

OS General

Shutdown main contactor;

Shutdown motor;

Shutdown EM bake;

Shutdown Throttle;

Shutdown interlock

Shutdown Driver 1;

Shutdown Driver 2;

Shutdown Driver 3

Shutdown Driver 4;

Shutdown PD;

Full brake.

1.

Internal controller fault.

If cycle key switch does not

clear fault, controller may

have failed.

72

PDO Timeout

Shutdown interlock;

CAN NMT State set to Pre-operational

1.

Internal controller fault.

Cycle key switch to clear

fault.

73

Stall Detect

Control mode changed to LOS.

1.

Stalled motor.

2.

Faulty motor encoder.

3.

Faulty wiring to encoder.

4.

Encoder power supply fault.

Encoder power supply is

provided by pin-26 from

controller.

Summary of Contents for B0-T48-48 Taylor Truck T48

Page 2: ......

Page 14: ...TAYLOR DUNN...

Page 30: ...TAYLOR DUNN...

Page 68: ...Maintenance Service and Repair Steering Page 22 Exploded View of Steering Gear...

Page 86: ...TAYLOR DUNN...

Page 112: ...TAYLOR DUNN...

Page 118: ...TAYLOR DUNN...

Page 130: ...TAYLOR DUNN...

Page 140: ...TAYLOR DUNN...

Page 152: ...Illustrated Parts Parts Page 2 Front Axle...

Page 154: ...Illustrated Parts Parts Page 4 Steering Knuckle...

Page 156: ...Illustrated Parts Parts Page 6 Steering Linkage...

Page 162: ...Illustrated Parts Parts Page 12 Rear Suspension View from rear...

Page 164: ...Illustrated Parts Parts Page 14 Transmission Gear Case...

Page 168: ...Illustrated Parts Parts Page 18 Rear Brakes Front Brakes...

Page 170: ...Illustrated Parts Parts Page 20 Brake Lines and Master Cylinder...

Page 172: ...Illustrated Parts Parts Page 22 Motor...

Page 174: ...Illustrated Parts Parts Page 24 Motor Mount Apply 94 421 34 grease to inside of motor coupler...

Page 186: ...Illustrated Parts Parts Page 36 Batteries FRONT OF VEHICLE...

Page 188: ...TAYLOR DUNN...