Summary of Contents for C0-426-48AC

Page 6: ......

Page 12: ...Page 12 MC 425 15 Introduction C 426 Notes...

Page 28: ...Lubrication Page 28 C 426 MC 425 15 Notes...

Page 38: ...Front Axle Page 38 C 426 MC 425 15 Notes...

Page 46: ...Steering Page 46 C 426 MC 425 15 Exploded View of Steering Gear...

Page 48: ...Steering Page 48 C 426 MC 425 15 Notes...

Page 60: ...Motor Page 60 C 426 MC 425 15 Notes...

Page 90: ...Replacement Parts Page 90 MC 425 15 C 426 REAR AXLE TRANSMISSION ASSEMBLY...

Page 92: ...Replacement Parts Page 92 MC 425 15 C 426 GT TRANSAXLE ASSEMBLY REAR...

Page 97: ...Replacement Parts Page 97 Not available at time of printing MC 425 15 C 426...

Page 98: ...Replacement Parts Page 98 MC 425 15 C 426 BRAKES BRAKE LINES...

Page 104: ...Replacement Parts Page 104 MC 425 15 C 426 DECALS STANDARD FRAME...

Page 106: ...Replacement Parts Page 106 MC 425 15 C 426 DECALS CAB FRAME...

Page 108: ...Replacement Parts Page 108 MC 425 15 C 426 ELECTRICAL MISCELLANEOUS...

Page 110: ...Replacement Parts Page 110 MC 425 15 C 426 FRAME AND BODY P1...

Page 114: ...Replacement Parts Page 114 MC 425 15 C 426 LINKAGE BRAKE PEDAL...

Page 117: ...Replacement Parts Page 117 Not available at time of printing MC 425 15 C 426...

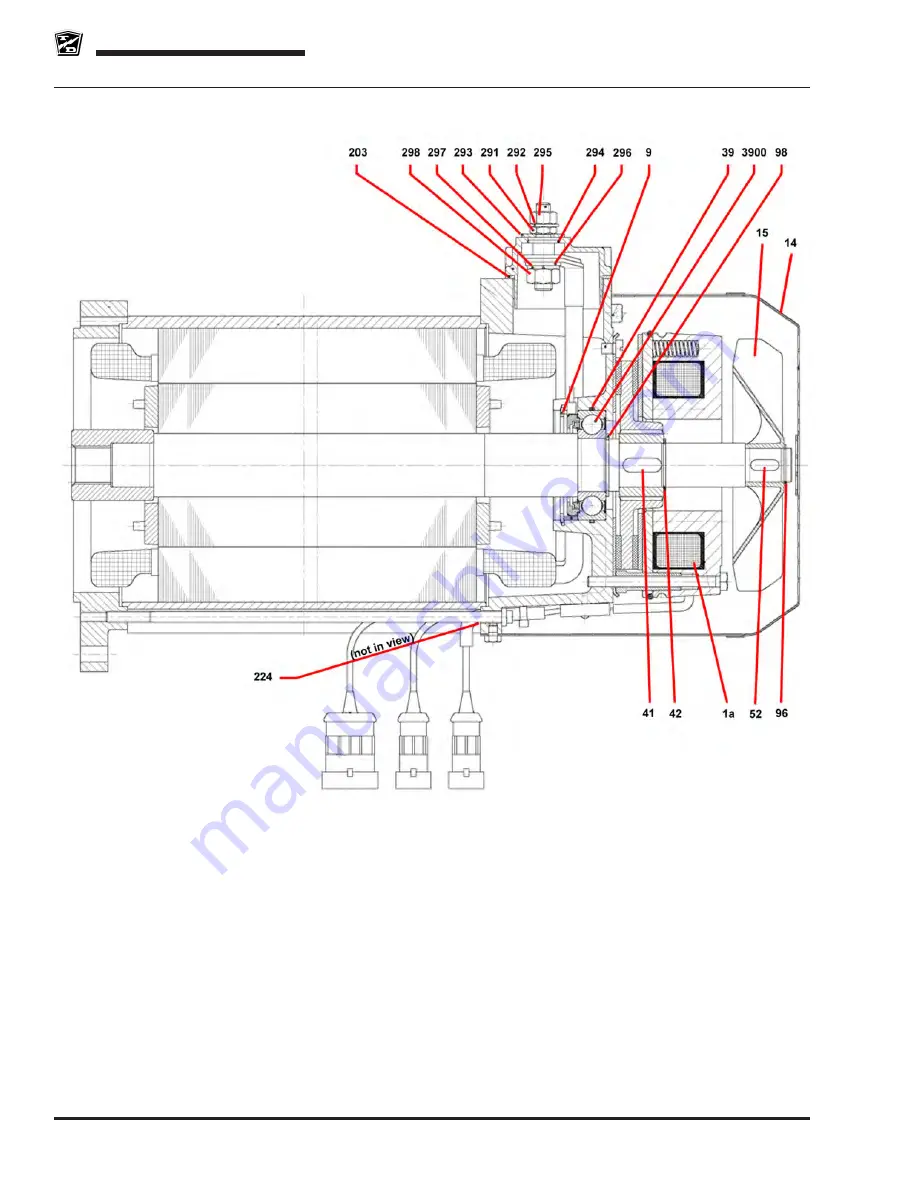

Page 118: ...Replacement Parts Page 118 MC 425 15 C 426 MOTOR...

Page 120: ...Replacement Parts Page 120 MC 425 15 C 426 Seat Mounting 1 on cowl SEATS...

Page 123: ...Replacement Parts Page 123 Not available at time of printing MC 425 15 C 426...

Page 124: ...Replacement Parts Page 124 MC 425 15 C 426 STEERING COLUMN...

Page 126: ...Replacement Parts Page 126 MC 425 15 C 426 SUSPENSION FRONT...

Page 130: ...Replacement Parts Page 130 MC 425 15 C 426 Notes...

Page 131: ......