Maintenance, Service, and Repair

Electrical Troubleshooting

Page 7

Throttle Module:

The throttle module is located under the floorboard and functions as a throttle position sensor. The

throttle module has two output signals, one is a varying voltage relative to the pedal position and the

other is a fixed voltage indicating that the pedal is depressed.

Other than the FS-1 switch, there are no static tests for the module. To test the module, it must be

connected to a power source. To bench test the FS-1 switch, check continuity between pins #4 and

#5. Should be closed only when the pedal is depressed. If open, replace the module.

The module can be bench tested by applying 36 volts to module pins #7 (+) and #9 (-).

For this procedure, the module will be tested while in the vehicle using the 75-089-00 test harness.

Testing in the vehicle will also help in identifying certain vehicle wiring faults.

The test harness plugs into the throttle module and vehicle harness. It has a long extension with a

connector that allows for direct voltage tests to all of the wires going to and from the module. The

vehicle should not be able run while the test harness is connected.

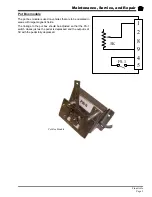

This illustration shows the test end of the harness and the orientation

of the terminals. The terminal numbers shown are exactly as on the

test harness.

NOTE: Perform the test for Pin #9 first, then use pin #9 as the battery

negative reference for all other tests.

Pin #9, 36 Volt negative input:

> Referencing battery positive, should be full battery voltage.

If not correct, check wiring.

Pin #1, #3 , #6, #8 - Not used on this vehicle.

Pin #2, throttle position output:

> Test voltage while slowly depressing the throttle pedal. The voltage should vary

between 6 Volts (creep) and 11 Volts (full speed).

If out of range AND Pin #7 AND Pin #9 tested good, then replace the module.

Pin #4, 12 Volt input:

< Should be 12 Volts (nominal).

If not correct, check the key switch, CB1, and D1.

Pin #5. 12 Volt output (FS-1):

> With pedal UP, should be 0 Volts. With pedal depressed (any position) should be 12

Volts (nominal).

If 12 Volts with pedal up, then check module FS-1 for welded contacts or vehicle wiring for

shorts.

If not 12 Volts with the pedal depressed AND Pin #4 tested good, then replace the module.

Pin #7, +36 Volt input:

> Should be between 25 and 40 Volts with the key switch ON (ISO contactor closed).

If out of range, check resistor R, CB2, and ISO contacts.

NOTE: An incorrect voltage could also be a result of a defective module.

Summary of Contents for ET-015-00

Page 2: ......

Page 14: ...TAYLOR DUNN...

Page 28: ...TAYLOR DUNN...

Page 48: ...Maintenance Service and Repair Steering Page 12 Exploded View of Steering Gear...

Page 60: ...Maintenance Service and Repair F2 F3 Transmission Page 12 EXPLODED VIEW...

Page 71: ...Maintenance Service and Repair Brakes Page 11 Rear Brake left side shown...

Page 72: ...TAYLOR DUNN...

Page 80: ...TAYLOR DUNN...

Page 90: ...TAYLOR DUNN...

Page 94: ...TAYLOR DUNN...

Page 100: ...TAYLOR DUNN...

Page 114: ...TAYLOR DUNN...

Page 116: ...TAYLOR DUNN...

Page 130: ...Illustrated Parts Parts Page 14 Rear Axle Axle tube 4 5 6 7 3 2 Rear Brakes...

Page 132: ...Illustrated Parts Parts Page 16 Rear Suspension 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Drive Shaft...

Page 134: ...Illustrated Parts Parts Page 18 Motor direct drive Motor Mount direct drive...

Page 142: ...Illustrated Parts Parts Page 26 Instrument Panel dash...

Page 144: ...Illustrated Parts Parts Page 28 Speed Control Panel 1 2 3 4 5 6 7 8 9 10 11 12 4...

Page 152: ...Illustrated Parts Parts Page 36 Charger 2 1 15 12 11 4 3 5 8 10 6 7 9 13 14 16...