Maintenance, Service, and Repair

Steering

Page 9

9. Install in reverse order.

10. Realign the front wheels.

NOTE: Refer to the

Steering

section for information

regarding realignment of the front wheels.

11. Lower the vehicle.

12. Reconnect the main positive and negative cables

at the batteries.

13. Remove the blocks from behind the wheels.

14. Release the park brake and test drive the vehicle.

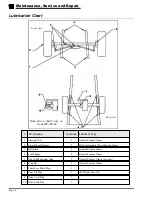

Replacing the Tie Rod

The Tie Rod is the linkage that connects the two steering

knuckles together. Refer to the illustration below..

6. Raise the front of the vehicle and support with

jack stands.

7. Remove the ball joints or rod ends from the

steering knuckles.

NOTE: Refer to the

Replacing the Ball Joints

section for information regarding the removal

of the ball joints or rod ends.

8. Remove the tie rod as an assembly.

9. Install in reverse order.

10. Realign the front wheels.

NOTE: Refer to the

Steering

section for information

regarding realignment of the front wheels.

Always use a lifting strap, hoist, and jack

stands, of adequate capacity to lift and

support the vehicle. Failure to use lifting

and support devices of rated load capacity

may result in severe bodily injury.

1. Make sure the key-switch is in the “OFF”

position, then remove the key.

2. Place the forward-reverse switch in the

center “OFF” position.

3. Confirm the electric park brake is set.

4. Place blocks under the front wheels to

prevent vehicle movement.

5. Disconnect the main positive and

negative cables at the batteries.

11. Lower the vehicle.

12. Reconnect the main positive and negative cables

at the batteries.

13. Remove the blocks from behind the wheels.

14. Release the park brake and test drive the vehicle.

CENTER THE STEERING GEAR

NOTE: The drag link must be disconnected from the

pitman arm or the pitman arm removed from

the steering gear to perform this procedure.

Refer to the appropriat section for details.

1. Remove the pitman arm.

2. Rotate the input shaft clockwise until it stops.

3. While counting the rotations, rotate the input shaft

counter clockwise until it stops.

4. Rotate the input shaft clockwise 1/2 the rotations

counted in the previous step.

5. Mark the input and pitman shaft in relation to the

housing.

Summary of Contents for ET-015-00

Page 2: ......

Page 14: ...TAYLOR DUNN...

Page 28: ...TAYLOR DUNN...

Page 48: ...Maintenance Service and Repair Steering Page 12 Exploded View of Steering Gear...

Page 60: ...Maintenance Service and Repair F2 F3 Transmission Page 12 EXPLODED VIEW...

Page 71: ...Maintenance Service and Repair Brakes Page 11 Rear Brake left side shown...

Page 72: ...TAYLOR DUNN...

Page 80: ...TAYLOR DUNN...

Page 90: ...TAYLOR DUNN...

Page 94: ...TAYLOR DUNN...

Page 100: ...TAYLOR DUNN...

Page 114: ...TAYLOR DUNN...

Page 116: ...TAYLOR DUNN...

Page 130: ...Illustrated Parts Parts Page 14 Rear Axle Axle tube 4 5 6 7 3 2 Rear Brakes...

Page 132: ...Illustrated Parts Parts Page 16 Rear Suspension 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Drive Shaft...

Page 134: ...Illustrated Parts Parts Page 18 Motor direct drive Motor Mount direct drive...

Page 142: ...Illustrated Parts Parts Page 26 Instrument Panel dash...

Page 144: ...Illustrated Parts Parts Page 28 Speed Control Panel 1 2 3 4 5 6 7 8 9 10 11 12 4...

Page 152: ...Illustrated Parts Parts Page 36 Charger 2 1 15 12 11 4 3 5 8 10 6 7 9 13 14 16...