Maintenance, Service, and Repair

Batteries

Page 5

Explosive mixtures of Hydrogen gas are

present within battery cells at all times. Do

not work with or charge battery in an area

where open flames (including gas furnace

or water heater pilots), sparks, cigarettes,

or any other sources of combustion are

present. Always provide ample ventilation

in rooms where batteries are being

charged. Failure to do so may result in

severe bodily injury and/or property

damage.

Battery electrolyte will stain and corrode

most surfaces. Immediately and

thoroughly clean any surface outside of the

battery that the battery electrolyte comes

in contact with. Failure to clean may result

in property damage.

1. Make sure the key-switch is in the “OFF”

position, then remove the key.

2. Place the forward-reverse switch in the

center “OFF” position.

3. Set the park brake.

4. Place blocks under the front wheels to

prevent vehicle movement.

5. Disconnect the main positive and

negative cables at the batteries.

A battery is a live electrical source. It

cannot be disconnected or neutralized. Do

not drop any tool or conductive object onto

the battery. A conductive object that comes

in contact with the battery terminals will

initiate a short circuit of the battery. This

could cause the battery to explode

resulting in severe bodily injury and/or

property damage.

Battery electrolyte is poisonous and

dangerous. It contains sulfuric acid. Avoid

contact with skin eyes or clothing. Wear

rubber gloves and safety glasses while

servicing batteries. DO NOT INGEST! This

may result in severe bodily injury.

Do not overfill the batteries. Over filling the

batteries may cause the battery electrolyte

to boil out of the battery and result in

severe bodily injury or property damage.

WATERING

NOTE: The electrolyte level in a battery rises while

charging and will be close to its highest level

after the end of a charging cycle. It is

recommended to fill the batteries at the end

of a charging cycle. If the electrolyte is below

the top of the battery plates then fill just

enough to cover the plates and then top off

when the charging cycle is complete.

6. Clean the batteries. Refer to

Cleaning the

Batteries

section for information on cleaning the

batteries.

7. Check the electrolyte level in all battery cells. If

low, fill to the correct level with distilled water using

part number

77-201-00

battery filler, never add

additional battery electrolyte to the batteries.

8. Reconnect the batteries, remove the blocks from

the wheels and test drive.

Summary of Contents for MB-238-00

Page 2: ......

Page 6: ...TAYLOR DUNN...

Page 28: ...TAYLOR DUNN...

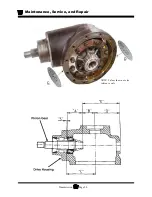

Page 44: ...Maintenance Service and Repair Steering Page 8 Exploded View of Steering Gear...

Page 64: ...TAYLOR DUNN...

Page 112: ...TAYLOR DUNN...

Page 149: ...TABLE OF CONTENTS Wire Diagrams Complete Vehicle 2...

Page 158: ...Illustrated Parts Parts Page 8 Transmission Gear Case...

Page 162: ...Illustrated Parts Parts Page 12 Rear Brakes Brake Body Assembly...

Page 166: ...Illustrated Parts Parts Page 16 Brake Lines Illustration not available...

Page 168: ...Illustrated Parts Parts Page 18 Motor...

Page 170: ...Illustrated Parts Parts Page 20 Wheels and Tires Ref wheel hub 1 2 3 Rear Suspension...

Page 172: ...Illustrated Parts Parts Page 22 Speed Control Panel Instrument Panel dash...

Page 182: ...Illustrated Parts Parts Page 32 Seat Cushions Deck and Lights Frame Illustration not available...

Page 184: ...Illustrated Parts Parts Page 34 Decals...