Drive Motor

Page 70

R-380 DC System

MR-380-03

REPAIR

Brushes

Note: It is recommended that all four brushes be replaced

as a set.

Note: The motor must be removed from the vehicle for

this procedure. Refer to Transmission Service

section for information on removing the motor.

The motor must be disassembled to replace the brushes or

the bearings. Refer to Disassembly section for information on

taking the motor apart.

Commutator

Note: The motor must be removed from the vehicle for

this procedure. Refer to Transmission Service

section for information on removing the motor.

1: The armature must be removed from the motor for this

procedure. Refer to Disassembly section for information

on taking the motor apart.

2: Using a lathe, cut the armature just enough to remove

all grooves, depressions or ridges.

3: Measure the diameter of the commutator. If the

commutator is less than the minimum diameter

specified in Service Limits, then the motor must be

replaced.

4: Thoroughly clean all copper debris from between the

commutator segments.

Note: Copper debris in the undercut area can give a

reading of a shorted armature.

5: Measure the commutator undercut depth in 5

places around the commutator. If any one of the

measurements is less than the minimum undercut

depth specified in Service Limits, then the commutator

must be undercut.

6:

While still in the lathe, smooth the commutator with fine

emery cloth.

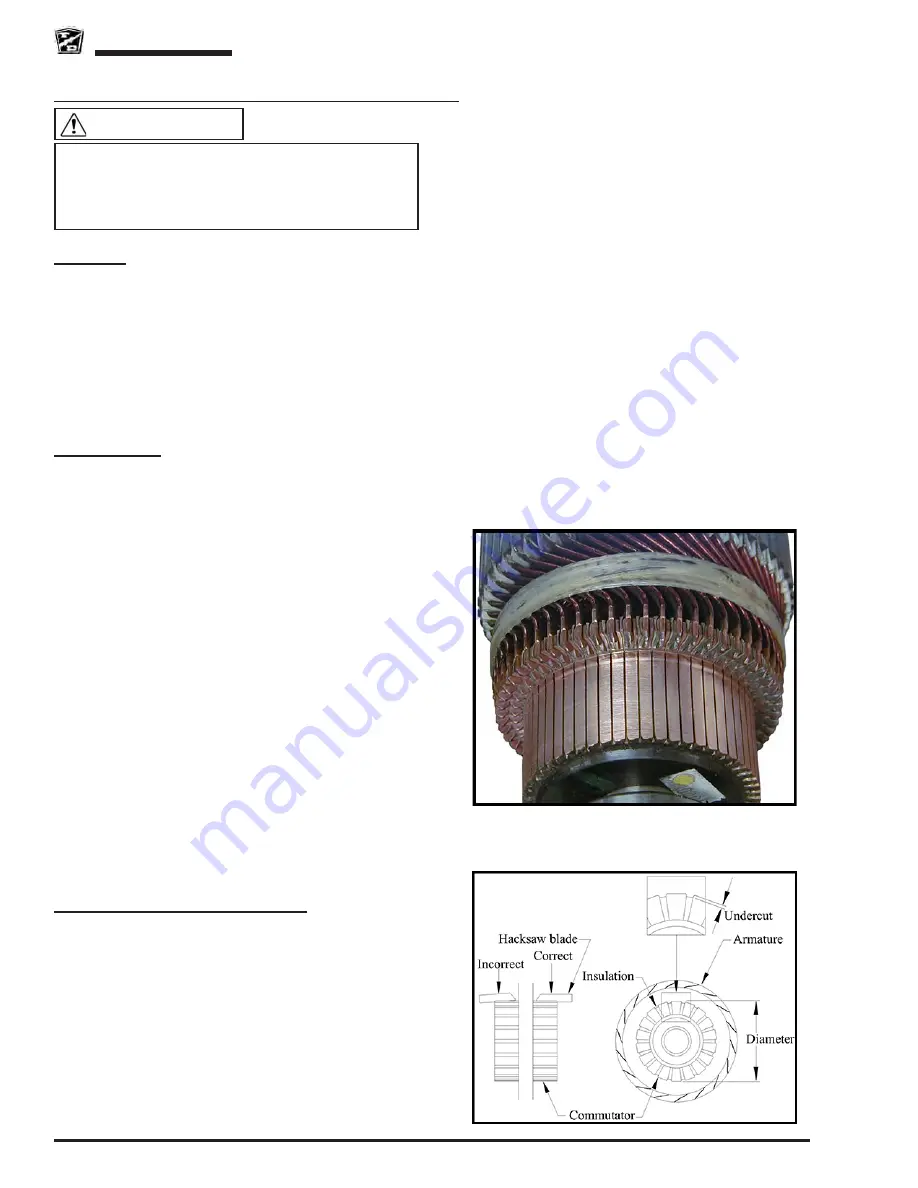

Undercutting the commutator

1: Using a small straight cut saw blade, cut the

commutator insulation to the proper depth. Refer to

undercut depth in Service Limits.

2: Once all segments have been properly undercut, mount

the armature in a lathe and smooth the commutator

with fine emery cloth.

3: Inspect the armature for shorts. Refer to Motor

Inspection section for information on testing the

armature.

Note: Copper debris in the undercut area can give a

reading of a shorted armature.

This section is one section of a complete service

manual. Before starting any procedure, read all

warnings and instructions that are located in the

Service Guidelines chapter.

WARNING

Properly cut and undercut commutator

Summary of Contents for R0-380-36

Page 6: ......

Page 12: ...Page 12 MR 380 03 Introduction R 380 DC System Notes...

Page 21: ...Table of Contents Special Tool List Special Tool List Troubleshooting Guide 23...

Page 24: ...Tool List Page 24 R 380 DC System MR 380 03 Notes...

Page 27: ...Lubrication Page 27 MR 380 03 R 380 DC System LUBRICATION DIAGRAM...

Page 28: ...Lubrication Page 28 R 380 DC System MR 380 03 Notes...

Page 44: ...Drive Axle Page 44 R 380 DC System MR 380 03 Notes...

Page 53: ...Steering Page 53 MR 380 03 R 380 DC System Exploded View of Steering Gear...

Page 72: ...Drive Motor Page 72 R 380 DC System MR 380 03 Notes...

Page 90: ...Tires Wheels Page 90 R 380 DC System MR 380 03 Notes...

Page 102: ...Replacement Parts Page 102 MR 380 03 R 380 DC System AXLE ASSEMBLY FRONT...

Page 104: ...Replacement Parts Page 104 MR 380 03 R 380 DC System AXLE REAR...

Page 106: ...Replacement Parts Page 106 MR 380 03 R 380 DC System BATTERY...

Page 108: ...Replacement Parts Page 108 MR 380 03 R 380 DC System BRAKES BRAKE LINES...

Page 114: ...Replacement Parts Page 114 MR 380 03 R 380 DC System BRAKES PARK BRAKE LINKAGE...

Page 118: ...Replacement Parts Page 118 MR 380 03 R 380 DC System CAB DOORS...

Page 136: ...Replacement Parts Page 136 MR 380 03 R 380 DC System STEERING LINKAGE...

Page 142: ...Replacement Parts Page 142 MR 380 03 R 380 DC System Notes...

Page 143: ......