12

Model 161

Important: To the Operator

130703

WASH Key

When the WASH key is pressed, the light comes on.

This indicates beater motor operation. The STANDBY

or AUTO mode must be cancelled first to activate the

WASH mode.

AUTO Key

When the AUTO key is pressed, the light comes on.

This indicates that the main refrigeration system has

been activated. In the AUTO mode, the WASH or

STANDBY functions are automatically cancelled. The

MIX REF function is automatically locked in to

maintain the temperature of the mix in the mix hopper.

Note:

An indicating light and an audible tone will

sound whenever a mode of operation has been

pressed. To cancel any function, press the key again.

The light and mode of operation will shut off.

Indicator Light - MIX LOW

Located on the front of the machine is a mix level

indicating light. When the light is flashing, it indicates

that the mix hopper has a low supply of mix and should

be refilled as soon as possible. Always maintain at

least 3” (76 mm) of mix in the hopper. If you neglect to

add mix, a freeze- up may occur. This will cause

eventual damage to the beater, blades, drive shaft,

and freezer door.

Reset Button

The reset button is located on the front of the unit. The

reset protects the beater motor from an overload

condition. If an overload occurs, the reset mechanism

will trip. To properly reset the freezer, press the AUTO

key to cancel the cycle. Turn the power switch to the

OFF position. Wait two or three minutes and then

press the reset button firmly.

Warning: Do not use metal objects to

press the reset button. Failure to comply may

result in severe personal injury or death.

Turn the power switch to the ON position. Press the

WASH key and observe the freezer’s performance. If

the beater motor is turning properly, press the WASH

key to cancel the cycle. Press the AUTO key on both

sides of the unit to resume normal operation. If the

freezer shuts down again, contact an authorized

service technician.

Feed Tube

The feed tube maintains overrun and allows enough

mix to enter the freezing cylinder after a draw. One end

of the tube has a mix delivery hole on the side and the

other end does not.

Figure 7

The feed tube serves two purposes.

1.

Normal Operation:

After priming the machine,

the end of the feed tube with the mix delivery hole

is placed in the mix inlet hole. Every time the draw

handle is raised, new mix and air from the hopper

will flow down into the freezing cylinder. This will

keep the freezing cylinder properly loaded and

will maintain overrun.

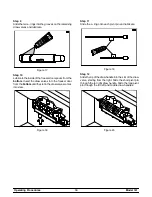

Feed Tube Position During Normal Operation:

Figure 8