OPERATING PROCEDURES

6-7

Models 358 and 359

Operating Procedures

6

Figure 6-23

3.

While the solution is flowing into the freezing cylinder,

brush-clean the mix hopper, mix-level sensing probe,

and mix inlet hole.

4.

Place the power switch in the Wash position. This will

cause the cleaning solution in the freezing cylinder to

be agitated.

5.

Place an empty pail beneath the door spout and raise

the draw handle. Draw off all the cleaning solution.

When the solution stops flowing from the door spout,

lower the draw handle and place the power switch in

the OFF position.

6.

Repeat steps 1 through 5

for the other side of the

freezer on Model 359.

Disassembly

WARNING!

Make sure the power switch is in

the OFF position before installing/removing any parts.

Failure to follow this instruction may result in severe

personal injury or electrocution.

Remove the freezer door, beater, scraper blades, and

driveshaft from the freezing cylinder. Take them to the

sink for cleaning.

1.

Repeat for the other side

of the freezer on Model

359.

2.

Remove the front drip tray and the splash shield.

Brush-Cleaning

1. Prepare a sink with an approved cleaning solution

(example: Kay-5

®

or Stera-Sheen

®

). Use warm water

and follow the manufacturer's specifications.

Important!

Follow label directions, since too

strong

of a solution can cause parts damage, while too

mild

of a solution will not provide adequate cleaning.

Make sure all brushes provided with the freezer are

available for brush-cleaning.

2. Remove the seal(s) from the driveshaft(s).

3. From the freezer door(s), remove:

•

Gasket(s)

•

Front bearing(s)

•

Draw valve(s)

Remove all O-rings.

Note:

To remove O-rings, use a single-service towel

to grasp the O-ring. Apply pressure upward until the

O-ring pops out of its groove. With the other hand,

push the top of the O-ring forward. It will roll out of the

groove and can be easily removed. If there is more

than one O-ring to be removed, always remove the

rear O-ring first. This will allow the O-ring to slide

over the forward rings without falling into the open

grooves.

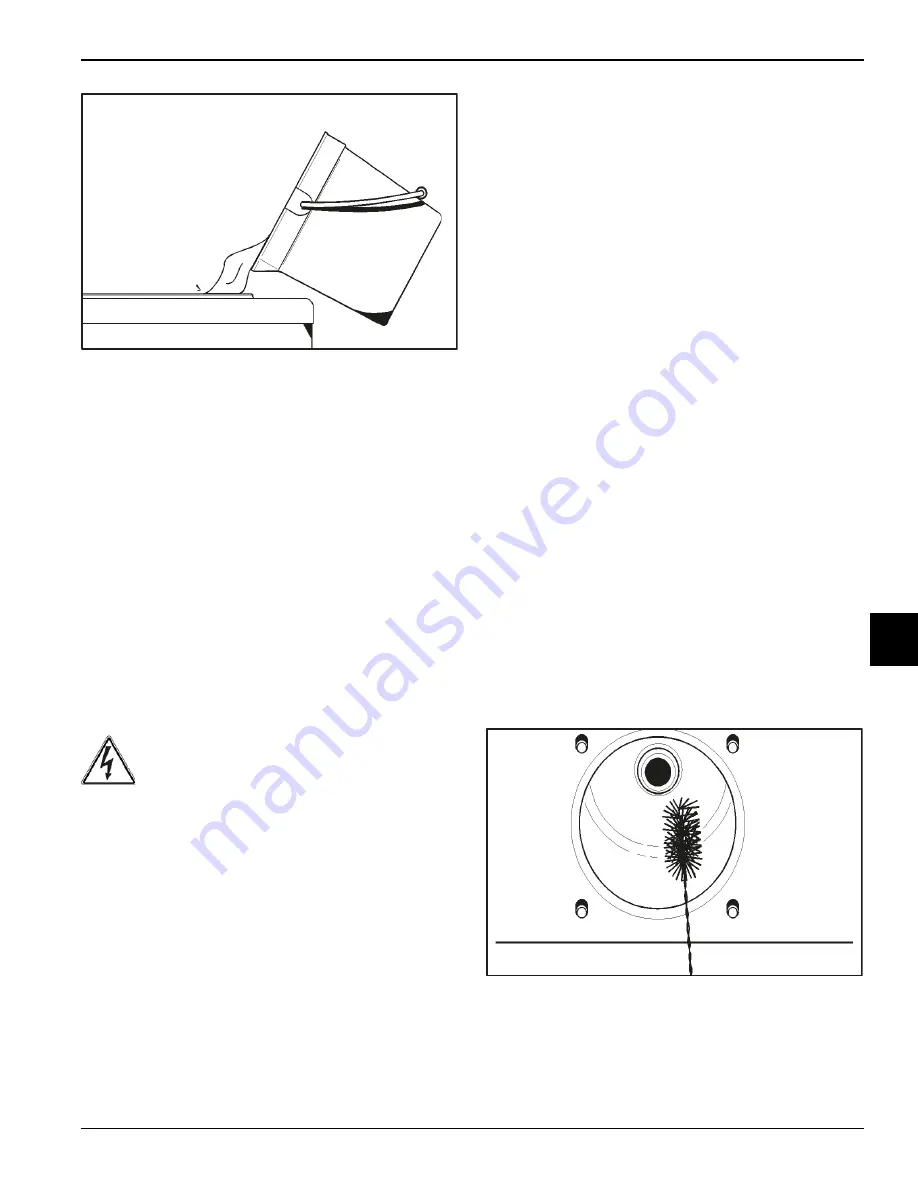

4. Return to the freezer with a small amount of cleaning

solution. With the black bristle brush, brush-clean the

rear shell bearing(s) at the back of the freezing

cylinder(s).

Figure 6-24