10

Models 369/370/371

from the condenser filter.

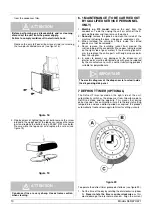

Remove the only left panel (from faucet side) unscrewing

the two plastic coated screws (see figure 18).

figure 18

3 - Replacement of lighted top cover bulb: remove the screw

placed in the upper part of the top cover, remove the lower

part and replace the bulb (using a 24-28V 21W max bulb).

Reassemble the top cover and replace the screw.(see

figure 19)

figure 19

6. 1 MAINTENANCE (TO BE CARRIED OUT

BY QUALIFIED SERVICE PERSONNEL

ONLY)

1 -

Monthly on 370 model

: remove the dust from the

condenser. To do this unplug the unit or switch off the 2-

pole wall breaker and then remove the panels.

2 -

Annually:

remove the panels and clean the inside of the

machine including the base, side panels, condenser, etc.

3 - When installed, the anti-splash filters inside the slotted

panels must not be removed.

4 - Never remove the insulating jacket from around the

suction tubing of the evaporator (the copper tubing located

on the right side of gear motor). If the insulating jacket is

missing replace the entire parts with original spare parts

from the supplier.

5 - In order to prevent any damages to the dispenser, all

plastics parts must be lubricated only with grease supplied

by the manufacturer or with another lubricating product

suitable for polycarbonate.

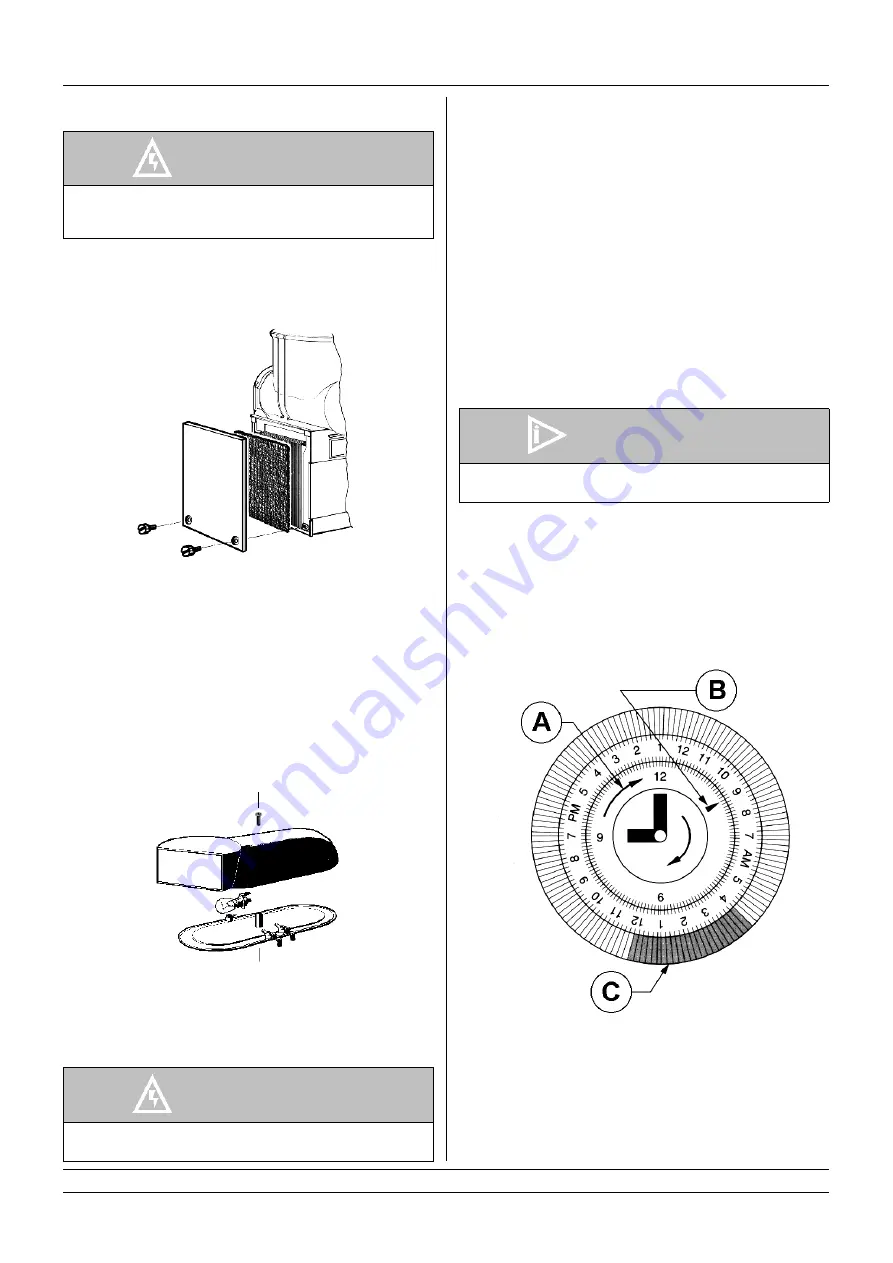

7 DEFROST TIMER (OPTIONAL)

The Defrost Timer, located on the right side of the unit,

automatically switches the dispenser from Granita mode to

Soft Drink mode and the opposite. This means that during

defrost periods frozen Granita will melt to thermostat setting

temperature and once defrost period has expired, the product

automatically freezes down again to Granita setting viscosity.

figure 20

To operate the defrost timer proceed as follows (see figure 20).

1 - Set the time of the day by rotating the dial clockwise (arrow

A).

Never rotate the timer counterclockwise

as this

would damage the internal machanism. Align the current

ATTENTION

Before performing any disassembly and/or cleaning

disconnect the unit from the power supply.

Failure to comply could result in electrical shock.

ATTENTION

Condenser fins are very sharp. Use extreme caution

when cleaning.

IMPORTANT

The electric diagram of the dispenser is located inside

the dispensing side panel.