OPERATING PROCEDURES

6-5

Model 632

Operating Procedures

6

Shake Side Freezing Cylinder

Assembly

Note:

When lubricating parts, use an approved food

grade lubricant (example: Taylor Lube).

WARNING!

Make sure the POWER SWITCH

is in the OFF position. Failure to follow this instruction

may result in severe personal injury from hazardous

moving parts.

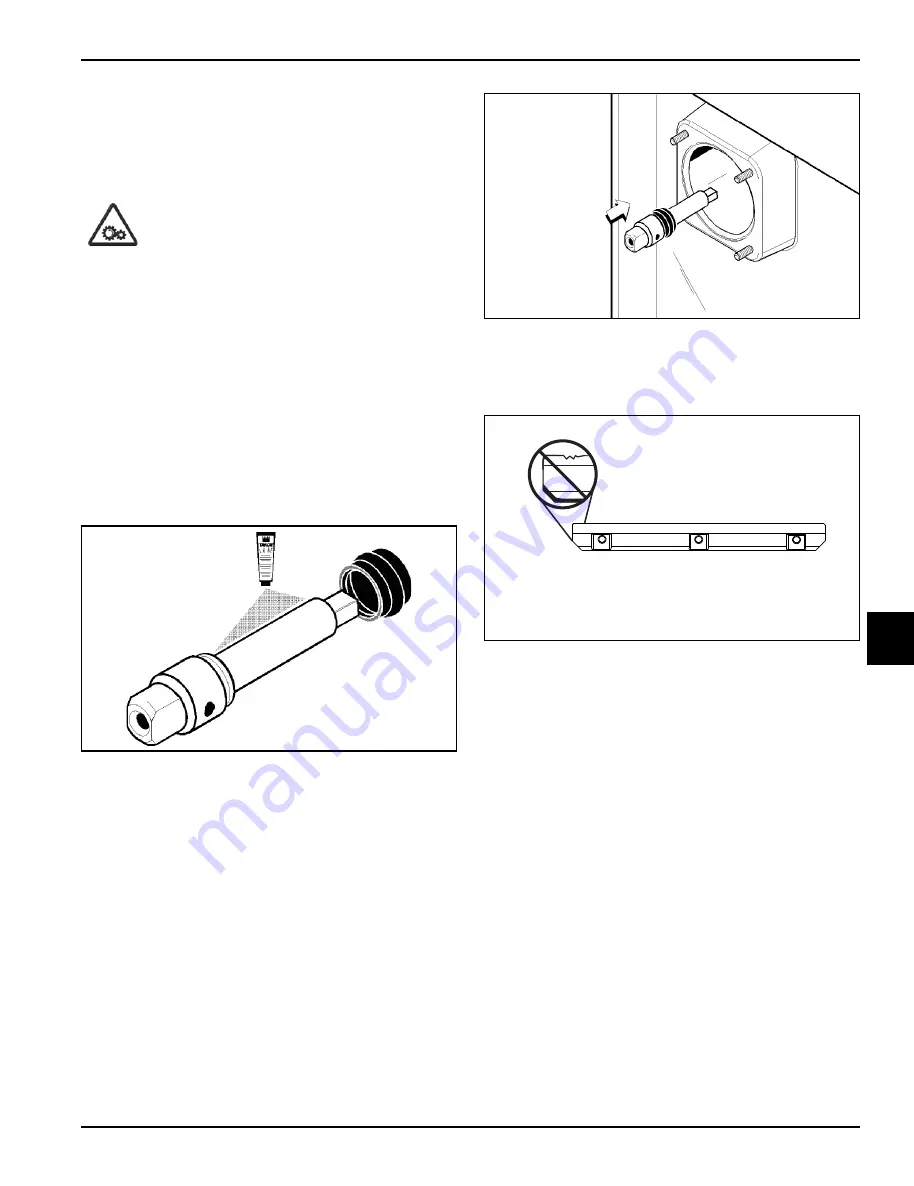

1. To install the drive shaft, lubricate the groove and

shaft portion that comes in contact with the bearing

on the beater drive shaft. Slide the seal over the shaft

and groove until it snaps into place.

Do not

lubricate

the hex end of the drive shaft. Fill the inside portion of

the seal with 1/4 in. (6.3 mm) more lubricant and

lubricate the flat side of the seal that fits onto the rear

shell bearing.

Figure 6-17

2. Insert the drive shaft into the freezing cylinder, hex

end first, and into the rear shell bearing, until the seal

fits securely over the rear shell bearing. Engage the

hex end firmly into the drive coupling. Make sure the

drive shaft fits into the drive coupling without binding.

Figure 6-18

3. Before installing the beater assembly, inspect the

scraper blades for any signs of wear or damage. If a

scraper blade is nicked or worn, replace both blades.

Figure 6-19

11547A

All manuals and user guides at all-guides.com