Section 8

8-1

Model 632

Troubleshooting Guide

8

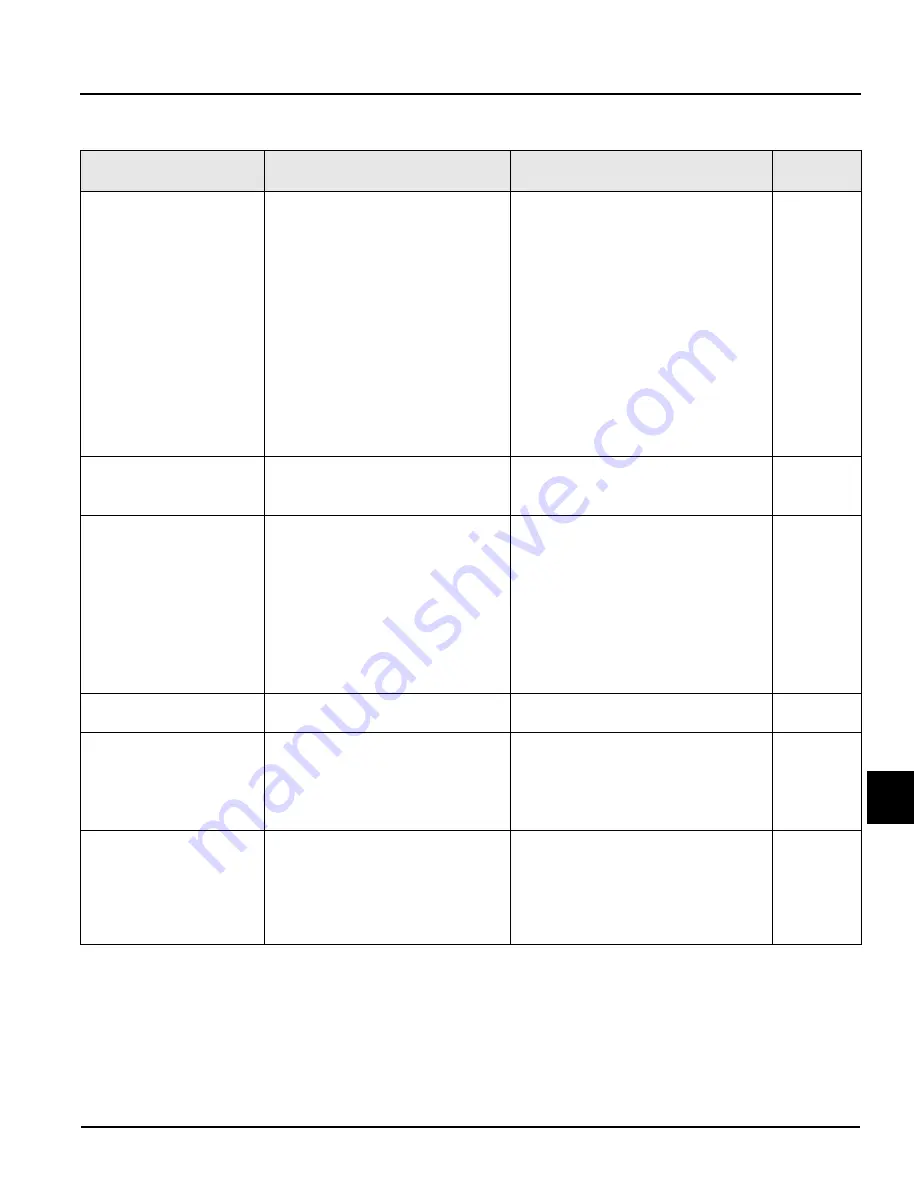

Troubleshooting Guide

Table 8-1

Problem

Probable Cause

Remedy

Page

Ref.

1. No product is being

dispensed with draw

valve open and the

machine in the Auto

mode.

a. Freeze-up in mix inlet hole.

a. Call a service technician to adjust the

mix hopper temperature.

- - -

b. Beater motor out on reset.

b. Reset the freezer.

5-2

c. The beater is rotating

counterclockwise from the

operator end.

c. Contact a service technician to

correct rotation to clockwise from

operator end.

- - -

d. The circuit breaker is off or the fuse

is blown.

d. Turn the breaker on, or replace the

fuse.

- - -

e. There is inadequate mix in the mix

hopper.

e. Fill the mix hopper with mix.

6-9

f. The air orifice is not installed (soft

serve only).

f. Install air orifice in air tube.

6-4

2. The product is too stiff.

a. The viscosity needs adjustment.

a. Contact a service technician.

- - -

b. The air orifice is not installed (soft

serve only).

b. Install air orifice in air tube.

6-4

3. The product is too soft.

a. The viscosity needs adjustment.

a. Contact a service technician.

- - -

b. Not enough air space around

machine. (Air-cooled machines.)

b. Allow for adequate air flow across the

condenser.

1-2

c. Worn scraper blades.

c. Replace regularly.

9-1

d. Dirty condenser

(Air-cooled machines.)

d. Clean monthly.

7-2

e. Mix is out of date.

e. Use only fresh mix.

- - -

f. Loss of water.

(Water-cooled machines.)

f. Locate cause of water loss and

correct.

7-2

4. The mix in the mix

hopper is too cold.

a. The temperature is out of

adjustment.

a. Call a service technician to adjust the

mix hopper temperature.

- - -

5. The mix in the mix

hopper is too warm.

a. The temperature is out of

adjustment.

a. Call a service technician to adjust the

mix hopper temperature.

- - -

b. The mix hopper cover is not in

position.

b. Place the cover in position.

- - -

c. The MIX light is not lit.

c. Press the MIX key.

5-2

6. The drive shaft is stuck

in the drive coupling.

a. Rounded corners of drive shaft,

coupling, or both.

a. Call a service technician to correct

cause, and to replace the necessary

components. Do not lubricate the hex

end of the drive shaft.

- - -

b. Mix and lubricant collected in the

drive coupling.

b. Brush clean the rear shell bearing

area regularly.

6-11

All manuals and user guides at all-guides.com