2-2

CONTROLS

Model C152 & C161

Controls

2

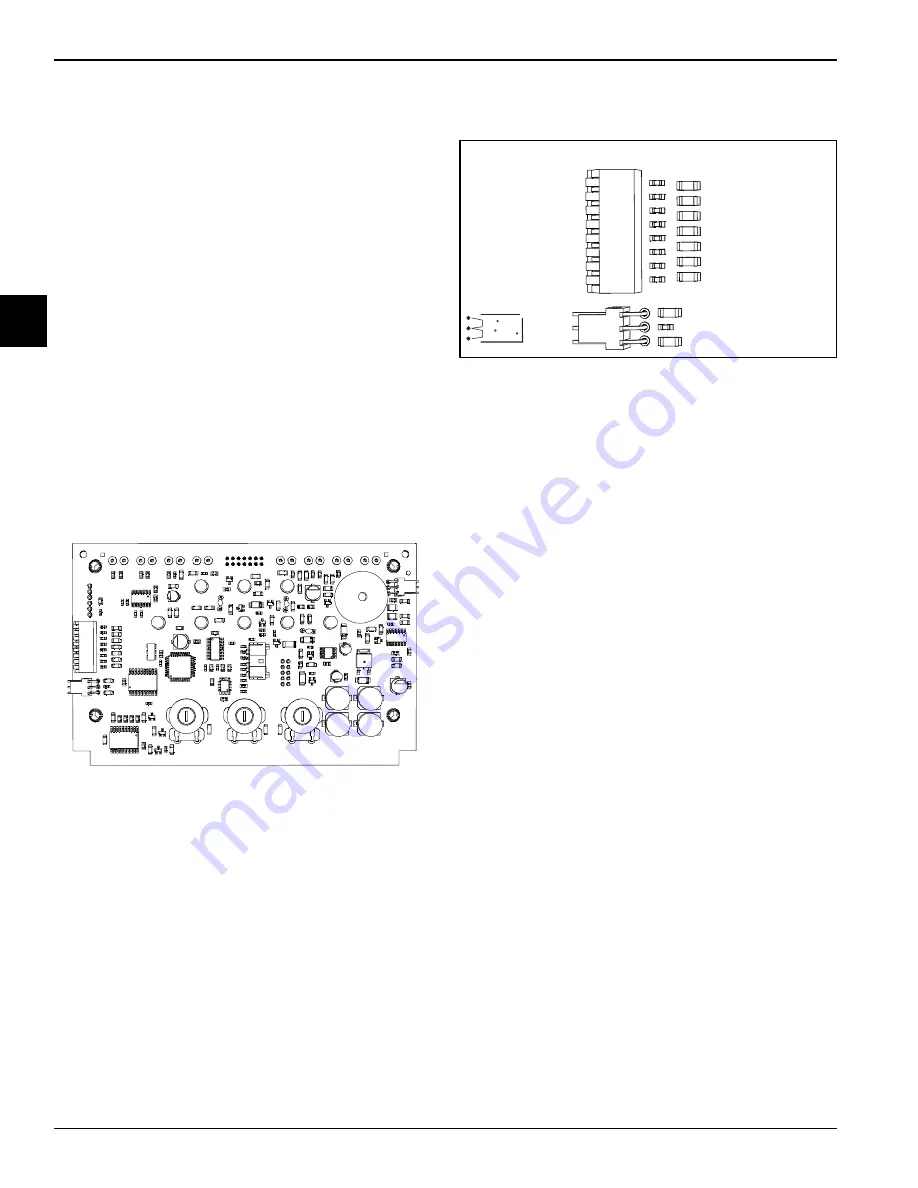

Generation II Control Logic Board

The Generation II logic board's primary function is to

interpret modes of operation. The board monitors mix

levels and temperatures by sending commands to the

control's power board. Commands are sent via a ribbon

cable, enabling the proper relays on the power board to

open or close. See Figure 2-4.

Function

Interpret a mode of operation/monitor mix level and

temperature/monitor product viscosity or product

temperature and send a command to the power board

through a ribbon cable, enabling the proper relays on the

power board to be open or closed.

Logic Board Part Number

See Figure 2-1 for an illustration of the logic board (part

number X69571SER3).

Figure 2-1

Dip Switch and Jumpers

Dip switches and jumpers are located on the logic board,

see Figure 2-1. For descriptions of dip switches, See

Figure 2-2.

Figure 2-2

Power Board Part Number

See Figure 2-4 for an illustration of the power board (part

number X69574-SER).

Thermistor Probes

There are two types of thermistor probes used on these

freezers. The resistance value of the thermistor probes

corresponds with the temperature. As the temperature

increases, the probe resistance decreases.

Approximate Probe Resistance Readings

•

10,000 ohm at room temperature 77

º

F (25

º

C).

•

30,035 ohm at hopper temperature 35

º

F (2

º

C).

•

48,636 ohm at soft serve temperature

18

º

F (-7.7

º

C).

Viscosity Function

In soft-serve freezers, the logic board monitors draw

amperage on the beater motor, which is directly related to

the viscosity of the product in the freezing cylinder. When

the amp draw reaches its set point, the machine cycles

off. Therefore, the viscosity of the product will always be

consistent even though its temperature may vary slightly.

To monitor amperage, L1 power supplied to the beater

motor must pass through the power board beater

terminals. The same Softech

™

controls are used in both

X31602

-

Barrel Probe (senses temperature of

product in freezing cylinder)

X55540

-

Hopper Probe (senses temperature of

mix in hopper)

1

2

3

4

5

6

7

8

DIP SWITCH

UP = OFF

1-COMP 5

2-MIX LO CHIM

3-BTR 5

4-BTR 10

5-FAN 2

6-STBY DIS

7-INTERVAL

8-INTERVAL

SWITCH INTERVAL

7

8

TIME

OFF

OFF

OFF

OFF

ON

ON

ON

ON

16

14

11

5

MIX DIFF.

SHUNT

4.5

13

NO

JMPR

= 2

Summary of Contents for C152

Page 4: ...ii 085592 S Notes...

Page 30: ...2 12 CONTROLS Model C152 C161 Controls 2 Notes...

Page 36: ...3 6 TROUBLESHOOTING Model C152 C161 Troubleshooting 3 Notes...

Page 39: ...PARTS 4 3 Model C152 C161 Parts 4 Notes...

Page 56: ...4 20 PARTS Model C152 C161 Parts 4 Notes...

Page 88: ...6 10 WIRING DIAGRAMS Model C152 C161 Wiring Diagrams 6 Notes...