6-8

OPERATING PROCEDURES

Model C300

Operating Procedures

6

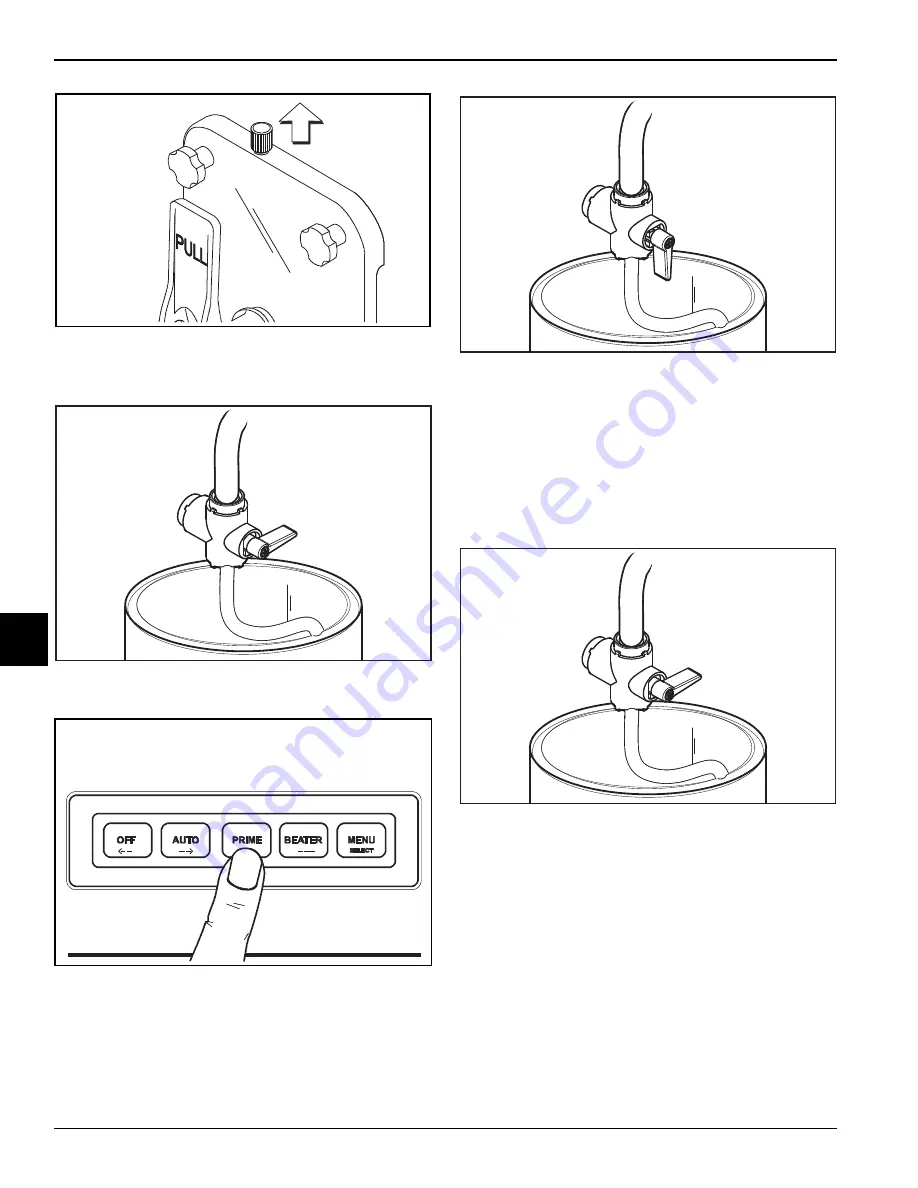

Figure 6-28

4.

Place the sampling valve in the OFF (center)

position.

Figure 6-29

5.

Press the PRIME (+ + +) key.

Figure 6-30

6.

Slowly move the syrup sampling valve to the fully

open position by turning the handle “down” toward

the sampling line. Allow the liquid to run into a pail

until all the sanitizer is removed and full-strength

product is flowing.

Figure 6-31

Note:

Brix is the ratio of syrup to water which will

directly affect the quality and taste of the product.

Brixing should be done before priming the freezer

and when a change in syrup flavor has been made.

7. Drain the product from the syrup sampling valve into

a cup. Close the syrup sampling valve by turning the

handle to the center position.

Figure 6-32

8. Stir the finished product. Pour a small amount of

product over the refractometer. The brix reading

should register 13 to 14. A reading higher than this

would cause a darker, richer product. The

refrigeration system would have to run longer to

freeze this excess syrup. A reading lower than this

could cause a freeze-up in the freezing cylinder

because of the excess water.

11229

18092

13039p

18032

18092

Summary of Contents for C300 NP

Page 14: ...3 4 SAFETY Model C300 Safety 3 Notes...

Page 18: ...4 4 OPERATOR PARTS IDENTIFICATION Model C300 Operator Parts Identification 4 Notes...

Page 26: ...5 8 USER INTERFACE Model C300 User Interface 5 Notes...

Page 40: ...6 14 OPERATING PROCEDURES Model C300 Operating Procedures 6 Notes...

Page 42: ...7 2 OPERATOR CHECKLIST Model C300 Operator Checklist 7 Notes...

Page 46: ...9 2 Model C300 Parts Replacement Schedule PARTS REPLACEMENT SCHEDULE 9 Notes...

Page 52: ...LIMITED WARRANTY ON PARTS 11 4 Model C300 Limited Warranty on Parts 11 Notes...