1-4

TO THE INSTALLER

Model C300

To the Installer

1

Beater Rotation

NOTICE!

Beater rotation must be clockwise as

viewed looking into the freezing cylinder.

To correct the rotation on a three-phase unit, interchange

any two incoming power supply lines at the freezer main

terminal block only. To correct rotation on a single-phase

unit, exchange leads inside the beater motor. (Follow the

diagram printed on the motor.)

Electrical connections are made directly to the terminal

block provided in the main control box located behind the

service panel.

It is recommended that beater rotation be performed by

an authorized Taylor service technician.

Initial Freezing Cylinder Cleaning

Due to the types of products used in FCB equipment, it is

imperative that the freezing cylinder and the inlet tube be

thoroughly brush cleaned, rinsed, and sanitized before

running any product.

Prepare a cleaning solution, using 2 oz. of liquid

detergent in 2 gallons of warm water. Using this solution,

brush clean the freezing cylinder and the inlet tube. Rinse

the freezing cylinder and the inlet tube with clean water

and then sanitize, using the sanitizing procedures

outlined in this Operator Manual, starting on page 6-5.

Refrigerant

CAUTION!

This equipment contains

fluorinated greenhouse gases (F-Gas) to provide

refrigeration using a hermetically sealed circuit or within

foam insulation. This unit's type of gas, quantity, Global

Warming Potential (GWP) and CO2 tonnes equivalent

information is recorded on the unit's data-label. The

refrigerant used is generally considered non-toxic and

non-flammable. However any gas under pressure is

potentially hazardous and must be handled with caution.

NEVER

fill any refrigerant cylinder completely with liquid.

Filling the cylinder to approximately 80% will allow for

normal expansion.

CAUTION!

Use only approved refrigerant

listed on the unit's data-label or authorized through a

manufacturer's technical bulletin. The use of any other

refrigerant may expose users and operators to

unexpected safety hazards.

WARNING!

Refrigerant liquid sprayed onto the

skin may cause serious damage to tissue. Keep eyes

and skin protected. If refrigerant burns should occur,

flush immediately with cold water. If burns are severe,

apply ice packs and contact a physician immediately.

NOTICE!

Taylor reminds technicians to be

aware of and in compliance with local government laws

regarding refrigerant recovery, recycling, and reclaiming

systems. For information regarding applicable local laws,

please contact your local authorized Taylor distributor.

IMPORTANT!

Refrigerants and their

associated lubricants may be extremely moisture

absorbent. When opening a refrigeration system, the

maximum time the system is open must not exceed 15

minutes. Cap all open tubing to prevent humid air or

water from being absorbed by the oil.

!

!

Summary of Contents for C300 NP

Page 14: ...3 4 SAFETY Model C300 Safety 3 Notes...

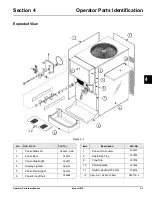

Page 18: ...4 4 OPERATOR PARTS IDENTIFICATION Model C300 Operator Parts Identification 4 Notes...

Page 26: ...5 8 USER INTERFACE Model C300 User Interface 5 Notes...

Page 40: ...6 14 OPERATING PROCEDURES Model C300 Operating Procedures 6 Notes...

Page 42: ...7 2 OPERATOR CHECKLIST Model C300 Operator Checklist 7 Notes...

Page 46: ...9 2 Model C300 Parts Replacement Schedule PARTS REPLACEMENT SCHEDULE 9 Notes...

Page 52: ...LIMITED WARRANTY ON PARTS 11 4 Model C300 Limited Warranty on Parts 11 Notes...