28

Model C300

Operating Procedures

Draining Product From the

Freezing Cylinder

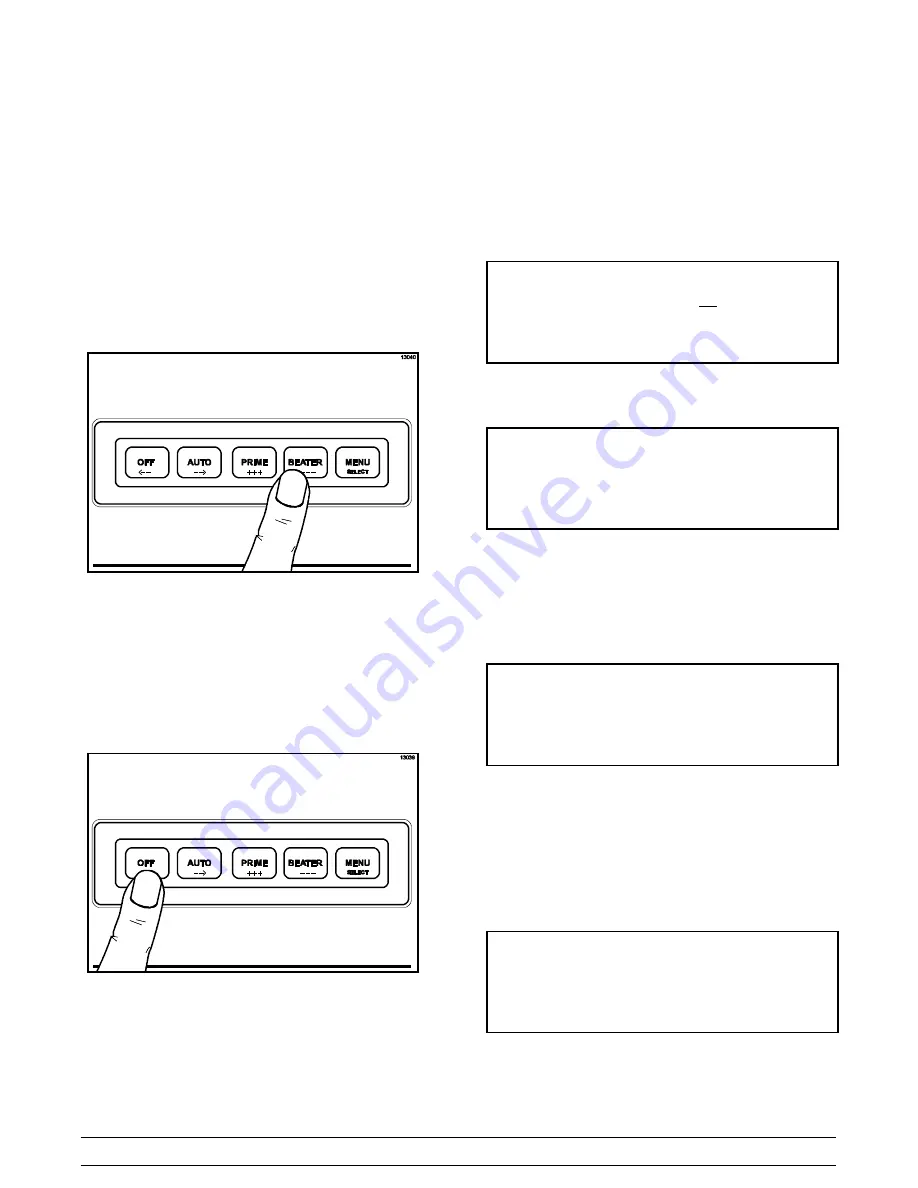

Step 1

With a pail beneath the door spout, press the

BEATER (-- -- --) key. This will allow the beater to

operate and CO

2

pressure will be maintained to

push the product from the freezing cylinder. Open

the draw valve and drain the product from the

machine until the CO

2

begins to jet.

Figure 42

Step 2

When all the product has been drained from the

freezing cylinder, close the draw valve and press the

OFF (<-- --) key. Discard this product.

Figure 43

Repeat Steps 1 and 2

for the other freezing

cylinder.

Rinsing

Step 1

To place the left cylinder in the RINSE mode, press

the MENU (SEL) key. Move the cursor by pressing

the AUTO (-- -->) key until the third line indicates

RINSE / SANITIZE.

OPERATOR MENU

A B C D E F G H I

RINSE / SANITIZE

<-- -- -- -->

SEL

Press the MENU (SEL) key. Move the cursor under

“RINSE” by pressing the OFF (<-- --) key twice.

RINSE / SANITIZE

RINSE

SANITIZE

EXIT

-- -- -- --

<-- -- -- -->

SEL

Step 2

Pressing the MENU (SEL) key will give you the

option for rinsing the left freezing cylinder. Move the

cursor under the word “YES”. Pressing the MENU

(SEL) key at this time will start the beater motor and

deliver water and CO

2

to the left cylinder.

RINSE

LEFT

SIDE

YES

NO

-- -- --

<-- -- -- -->

SEL

Step 3

Allow the rinse water to flow into the cylinder until it

is approximately 2/3 full. With a pail under the door

spout, open the draw valve and drain the rinse

water. Repeat this procedure until the rinse water

being drawn is clear.

Repeat Steps 2 -- 3 for the right side.

RINSE

RIGHT SIDE

YES

NO

-- -- --

<-- -- -- -->

SEL

When draining is complete, press the OFF (<-- --)

key.

Summary of Contents for C300 NP

Page 51: ...Model C300 059540 27 4 11...

Page 52: ...Model C300 059540 33 4 11...

Page 53: ...Model C300 059540 40 4 11...

Page 54: ...Model C300 059540 58 4 11...