Section 8

8-1

Model C300

Troubleshooting Guide

8

Troubleshooting Guide

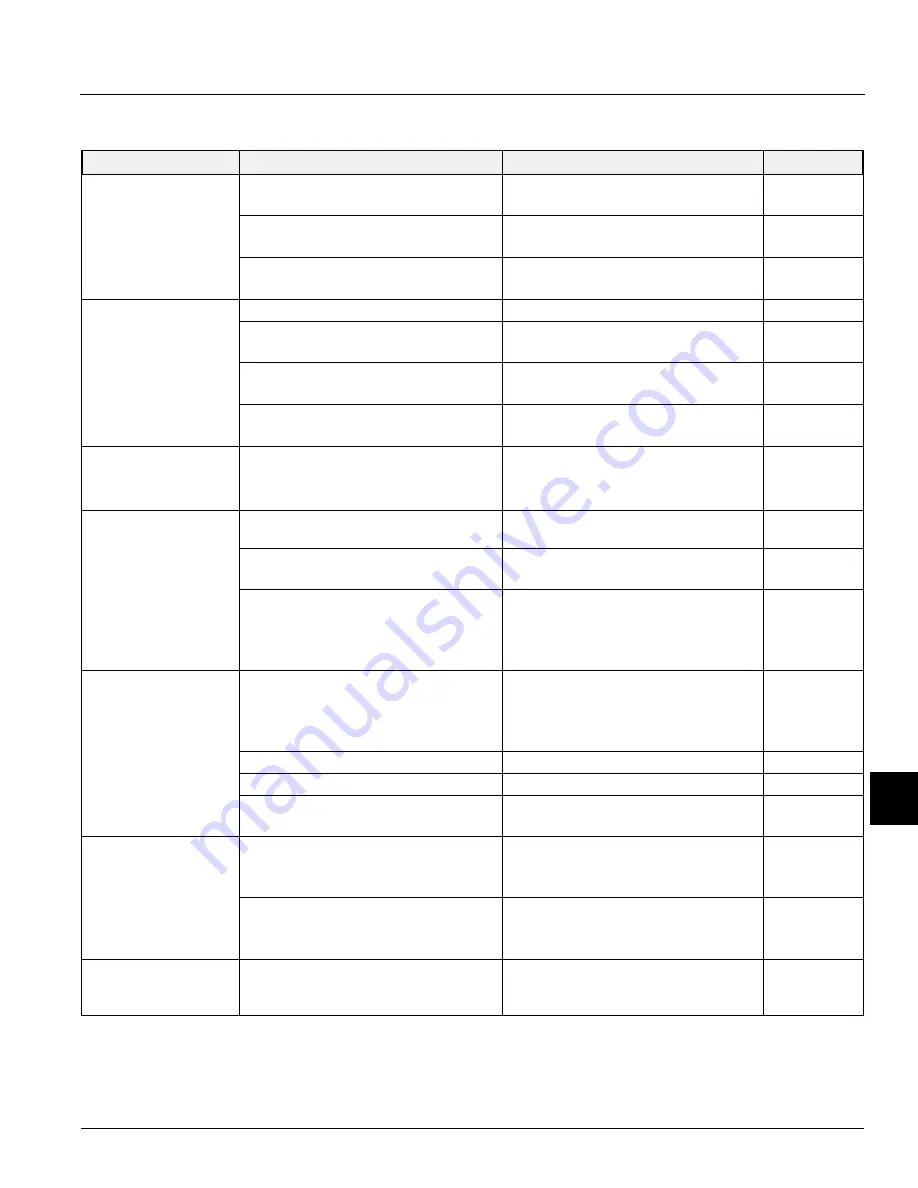

Table 8-1

Problem

Probable cause

Remedy

Page ref

1. Product is too

stiff.

a. Too much water to syrup ratio.

Improper brix adjustment.

a. Adjust the brix accordingly.

b. Consistency control needs

adjustment.

b. Contact a service technician.

- - -

c. Torque coupling bound in

warm

position.

c. Contact a service technician.

- - -

2. Product is too

soft.

a. Freezer in a defrost cycle.

a. Wait for defrost cycle to end.

- - -

b. Consistency control needs

adjustment.

b. Contact a service technician.

- - -

c. Torque coupling bound in

cold

position.

c. Contact a service technician.

- - -

d. Broken springs in torque

coupling.

d. Contact a service technician.

- - -

3. No product is

being

dispensed.

a. Product frozen-up in freezing

cylinder.

a. See problem No. 1.

- - -

4. Freezer will not

operate in the

Beater or Auto

modes.

a. Unit is unplugged.

a. Check the plug at wall receptacle.

- - -

b. Blown fuse, or the circuit breaker

is off.

b. Replace the fuse or turn the

breaker on.

- - -

c. Beater motor is out on overload.

Check fault description screen.

c. Allow the motor to cool. Press the

AUTO (- ->) key. Call a service

technician if the beater motor

goes out on overload again.

5. No compressor

operation in the

Auto mode.

a. Beater motor is out on overload.

Check the fault description

screen.

a. Allow the motor to cool. Press the

AUTO (- ->) key. Call a service

technician if the beater motor

goes out on overload again.

b. Condenser dirty, A/C.

b. Clean condenser monthly.

c. Water supply off, W/C.

c. Turn the water on.

- - -

d. The torque coupling is bound in

the COLD position.

d. Contact a service technician.

- - -

6. Unable to

remove the

drive shaft from

the rear shell

bearing.

a. Rounded corners of hex end of

drive shaft, drive coupling, or

both.

a. Replace the drive shaft, or call a

service technician to replace the

direct drive unit.

- - -

b. Lubrication of hex end of drive

shaft.

b. Do not lubricate the hex end. If

necessary, contact a service

technician for removal.

7. Excessive loss

of CO

2

.

a. Leak in the CO

2

system.

a. Contact a service technician.

- - -

Summary of Contents for C300 NP

Page 14: ...3 4 SAFETY Model C300 Safety 3 Notes...

Page 18: ...4 4 OPERATOR PARTS IDENTIFICATION Model C300 Operator Parts Identification 4 Notes...

Page 26: ...5 8 USER INTERFACE Model C300 User Interface 5 Notes...

Page 40: ...6 14 OPERATING PROCEDURES Model C300 Operating Procedures 6 Notes...

Page 42: ...7 2 OPERATOR CHECKLIST Model C300 Operator Checklist 7 Notes...

Page 46: ...9 2 Model C300 Parts Replacement Schedule PARTS REPLACEMENT SCHEDULE 9 Notes...

Page 52: ...LIMITED WARRANTY ON PARTS 11 4 Model C300 Limited Warranty on Parts 11 Notes...