OPERATING PROCEDURES

6-11

Model C303 & C314

Operating Procedures

6

5.

Allow the rinse water to flow into the cylinder

until it is approximately 2/3 full. With a pail under

the door spout, open the draw valve and drain

the rinse water.

Repeat this procedure

until the

rinse water being drawn is clear

6.

Repeat step 1 through step 5 for the remaining

freezing cylinder.

7.

When draining is complete, press the OFF (<- -) key.

Cleaning

1.

Prepare an approved 100 PPM cleaning solution.

(examples: 2-1/2 gal. [9.5 liters] Kay-5

®

or 2 gal. [7.6

liters] Stera- Sheen

®

). Use warm water and follow the

manufacturer's specifications.

Important!

Make sure the cleaner is completely

dissolved.

2.

Pour the cleaning/sanitizing solution into a clean,

empty pail. Place the syrup line with the old syrup

connector into the pail of cleaner.

3.

To place a freezing cylinder in the SANITIZE mode,

press the MENU SELECT key. Move the cursor by

pressing the AUTO (- ->) key until the third line

indicates RINSE / SANITIZE.

4.

Press the MENU SELECT key. Move the cursor

under the word "SANITIZE" by pressing the OFF (<- -

) key.

5.

Pressing the MENU SELECT key will give you the

option for sanitizing a freezing cylinder. Move the

cursor under the desired barrel.

6. Press the MENU SELECT key to start the sanitize

mode.

7. Repeat step 3 through step 6 for the remaining

freezing cylinder.

8. Open the prime plugs. Allow each cylinder to fill

approximately 2/3 full. Close each prime plug.

9. Continue filling the freezing cylinders with sanitizing

solution until the solution purges out of each relief

valve and begins draining into the front drip tray. The

relief valves are located at the top of each mix tank.

Press the OFF (<- -) key.

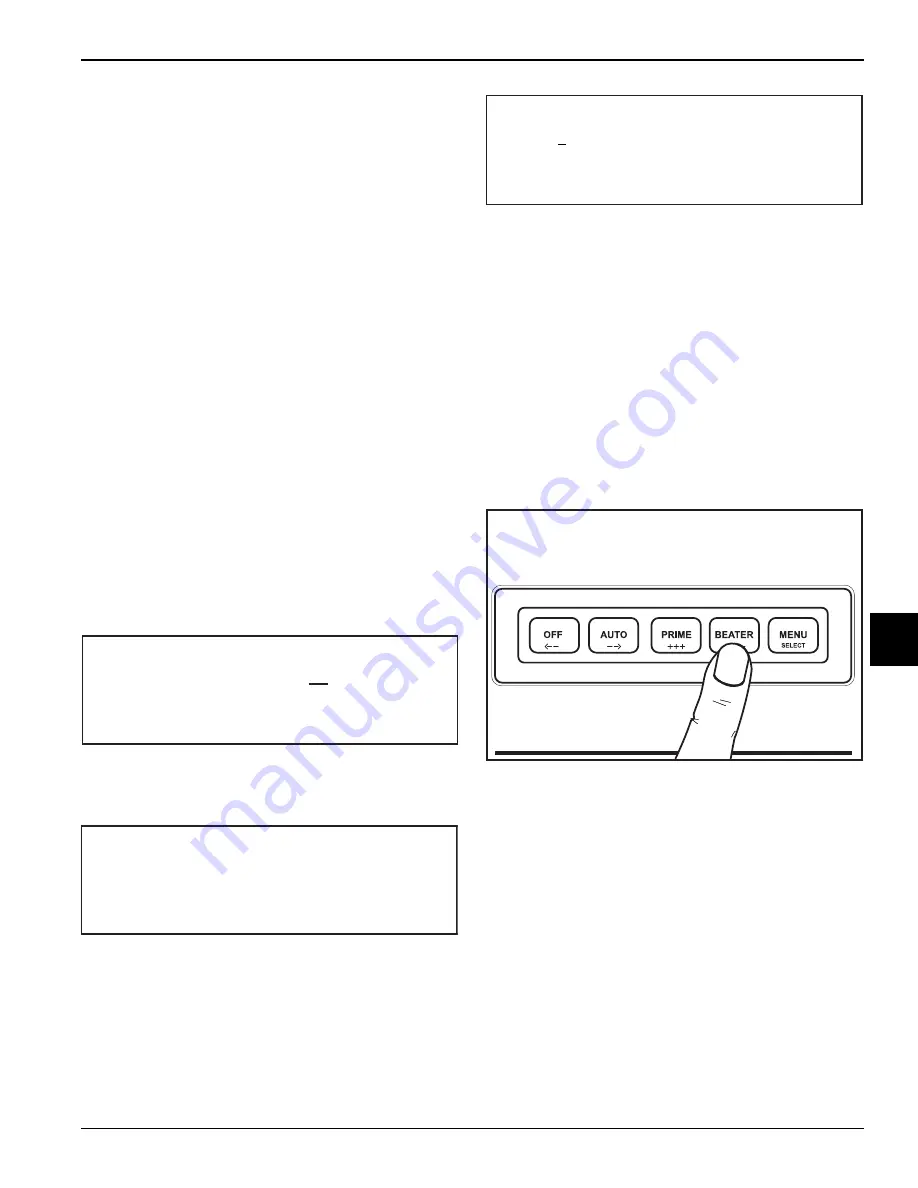

10. Press the BEATER (- - -) key to agitate the solution in

each freezing cylinder for five minutes.

Figure 6-40

11. With a pail beneath the door spouts, open the draw

valves and drain all the solution from the freezing

cylinders. Press the OFF (<- -) key and close the

draw valves.

OPERATOR MENU

A B C D E F G H I

RINSE / SANITIZE

L

E

S

>

-

-

-

-

<

RINSE / SANITIZE

RINSE

SANITIZE

EXIT

- - - - -

L

E

S

>

-

-

-

-

<

SEL

<- - - ->

EXIT

BRL 1

2

3

SANITIZE

13040

Summary of Contents for C303

Page 14: ...3 4 SAFETY Model C303 C314 Safety 3 Notes...

Page 41: ...OPERATING PROCEDURES 6 13 Model C303 C314 Operating Procedures 6...

Page 43: ...7 2 OPERATOR CHECKLIST Model C303 C314 Operator Checklist 7 Notes...

Page 47: ...9 2 PARTS REPLACEMENT SCHEDULE Model C303 C314 Parts Replacement Schedule 9 Notes...

Page 53: ...11 4 LIMITED WARRANTY ON PARTS Model C303 C314 Limited Warranty on Parts 11 Notes...