6-16

OPERATING PROCEDURES

Model C612

Operating Procedures

6

Manual Brush-Cleaning

These procedures must be completed according to the

frequency specified by your federal, state, or local

regulatory agencies. Please consult your governing food

code to determine the maximum number of days allowed

between brush-clean cycles.

Use the recommended cleaning procedure outlined in the

manual, or an alternate procedure used in conjunction

with a cleaning/sanitizing system that has been certified

by NSF.

1. Prepare a sink with an approved 100 ppm

cleaning/sanitizing solution (examples: Kay-5

®

or

Stera-Sheen

®

).

Important!

Use warm water and follow the

manufacturer's specifications.

Make sure all brushes provided with the freezer are

available for brush-cleaning.

2. Thoroughly brush-clean all disassembled parts in the

cleaning solution, making sure all lubricant and mix

film is removed. Make sure to brush all surfaces and

holes, especially the holes in the pump components

and the draw valve holes in the freezer door.

Rinse all parts with clean, warm water. Place the

parts on a clean, dry surface to air-dry overnight

(use parts trays, if available).

3. Return to the freezer with a small amount of cleaning

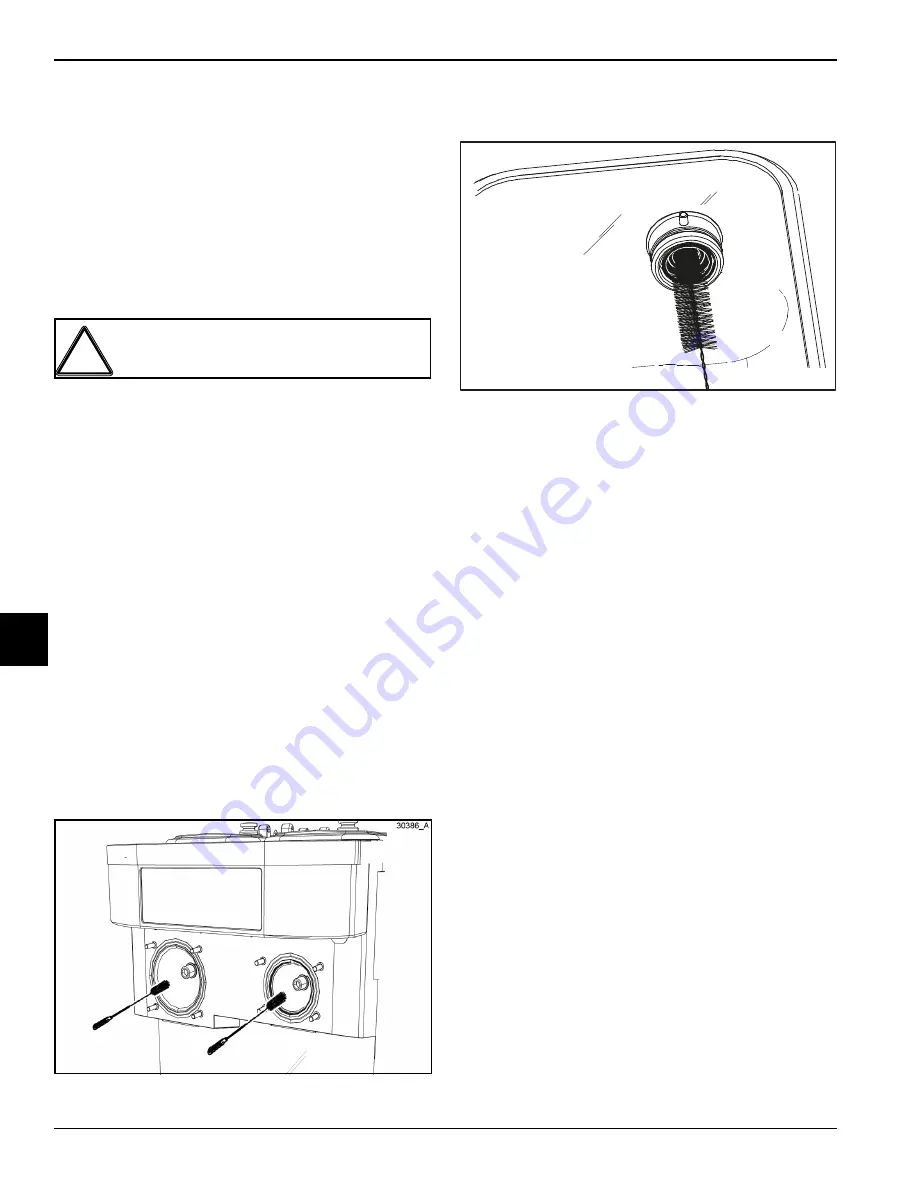

solution. Using the black brush, clean the rear shell

bearing at the back of each freezing cylinder.

Figure 6-58

4. Using the black brush, clean the drive hub opening in

the rear wall of each mix hopper. (See Figure 6-59.)

Figure 6-59

5. Wipe all exterior surfaces of the freezer with a clean,

sanitized towel.

Note:

The Brush-Clean Counter will reset to zero at

this time.

!

ALWAYS FOLLOW LOCAL HEALTH CODES.

12008

Summary of Contents for C612

Page 8: ...1 4 TO THE INSTALLER Model C612 To the Installer 1 Notes...

Page 54: ...9 2 PARTS REPLACEMENT SCHEDULE Model C612 Parts Replacement Schedule 9 Notes...

Page 58: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C612 Limited Warranty on Equipment 10 Notes...

Page 62: ...11 4 LIMITED WARRANTY ON PARTS Model C612 Limited Warranty on Parts 11 Notes...