Section 8

8-1

Model C706

Troubleshooting Guide

8

Troubleshooting Guide

Table 8-1

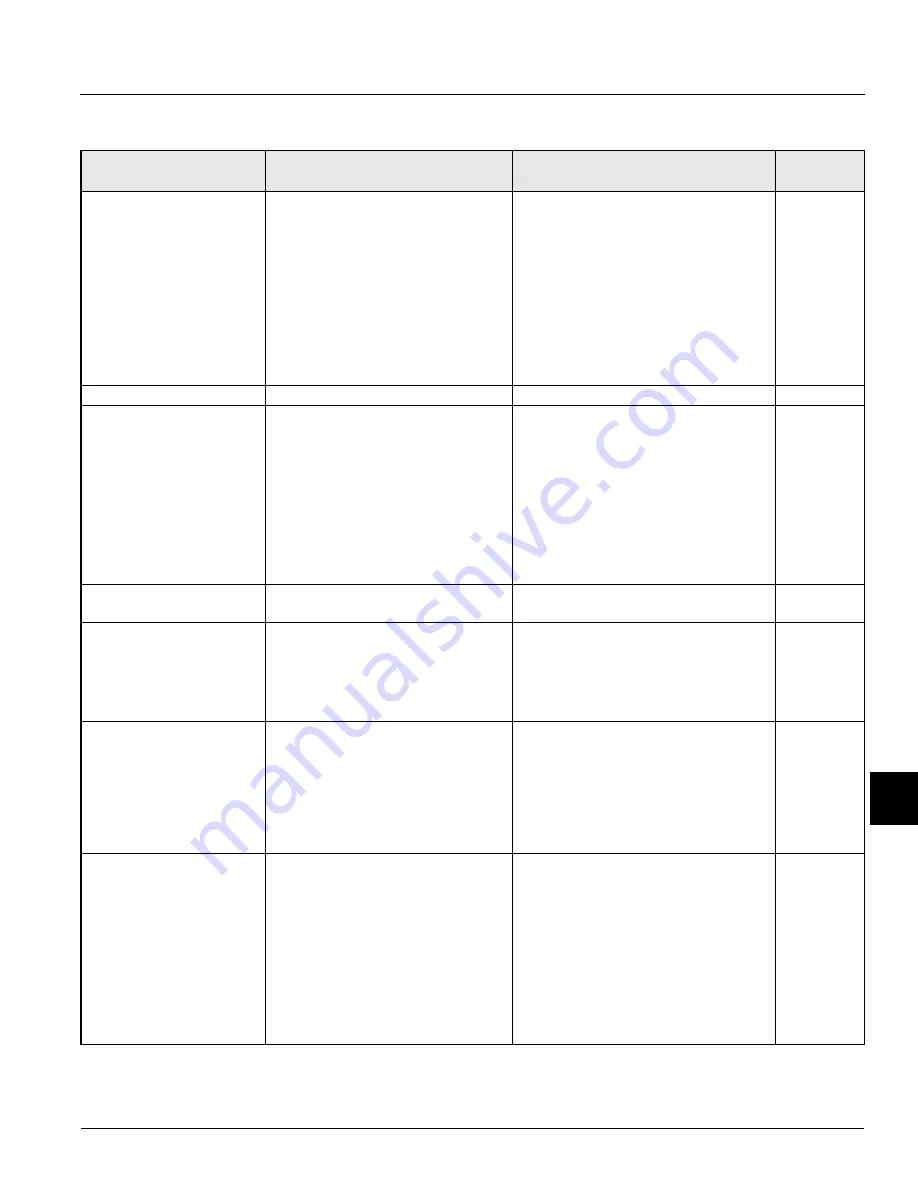

Problem

Probable Cause

Remedy

Page

Ref.

1. No product is being

dispensed with the draw

valve open and the

machine in the Auto

mode.

a. Freeze-up in mix inlet hole.

a. Call a Taylor service technician to

adjust the mix hopper temperature.

- - -

b. Beater motor out on reset.

b. Reset the freezer.

c. The beater is rotating

counterclockwise from the

operator end.

c. Contact a Taylor service technician to

correct rotation to clockwise from

operator end.

- - -

d. The circuit breaker is off or the fuse

is blown.

d. Turn the breaker on or replace the

fuse.

- - -

e. There is inadequate mix in the mix

hopper.

e. Fill the mix hopper with mix.

2. The product is too stiff.

a. The viscosity needs adjustment.

a. Contact a Taylor service technician.

- - -

3. The product is too soft.

a. Viscosity needs adjustment.

a. Contact a Taylor service technician.

- - -

b. Not enough airspace around

machine. (Air-cooled machines)

b. Allow for adequate airflow across the

condenser.

c. Worn scraper blades.

c. Replace regularly.

d. Dirty condenser. (Air-cooled

machines)

d. Clean monthly.

e. Mix is out of date.

e. Use only fresh mix.

- - -

f. Loss of water.

(Water-cooled machines)

f. Locate cause of water loss and

correct.

4. The mix in the mix

hopper is too cold.

a. The temperature is out of

adjustment.

a. Call a Taylor service technician to

adjust the mix hopper temperature.

- - -

5. The mix in the mix

hopper is too warm.

a. The temperature is out of

adjustment.

a. Call a Taylor service technician to

adjust the mix hopper temperature.

- - -

b. The mix hopper cover is not in

position.

b. Place the cover in position.

c. The MIX REF light is not lit.

c. Press the MIX REF key.

6. The driveshaft is stuck in

the drive coupling.

a. Rounded corners of driveshaft,

coupling, or both.

a. Call a Taylor service technician to

correct the cause and to replace the

necessary components. Do not

lubricate the hex end of the

driveshaft.

- - -

b. Mix and lubricant collected in the

drive coupling.

b. Brush clean the rear shell bearing

area regularly.

7. The freezing cylinder

walls are scored.

a. The scraper blades are damaged.

a. Replace the scraper blades.

b. Machine was placed in Auto mode

before all sanitizing solution was

removed from freezing cylinder.

b. Place machine in Auto mode only

after priming is complete and all

sanitizing solution is removed.

c. The front bearing is missing or

worn on the freezer door.

c. Install or replace the front bearing.

d. The beater assembly is bent.

d. Call a Taylor service technician to

repair or replace the beater and

correct the cause of insufficient mix in

the freezing cylinder.

- - -

Summary of Contents for C706

Page 8: ...1 4 TO THE INSTALLER Model C706 To the Installer 1 Notes ...

Page 14: ...3 4 SAFETY Model C706 Safety 3 Notes ...

Page 36: ...6 14 OPERATING PROCEDURES Model C706 Operating Procedures 6 Notes ...

Page 42: ...8 4 TROUBLESHOOTING GUIDE Model C706 Troubleshooting Guide 8 Notes ...

Page 44: ...9 2 PARTS REPLACEMENT SCHEDULE Model C706 Parts Replacement Schedule 9 Notes ...

Page 48: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C706 Limited Warranty on Equipment 10 Notes ...

Page 52: ...11 4 LIMITED WARRANTY ON PARTS Model C706 Limited Warranty on Parts 11 Notes ...