6-2

OPERATING PROCEDURES

Model C706

Operating Procedures

6

2.

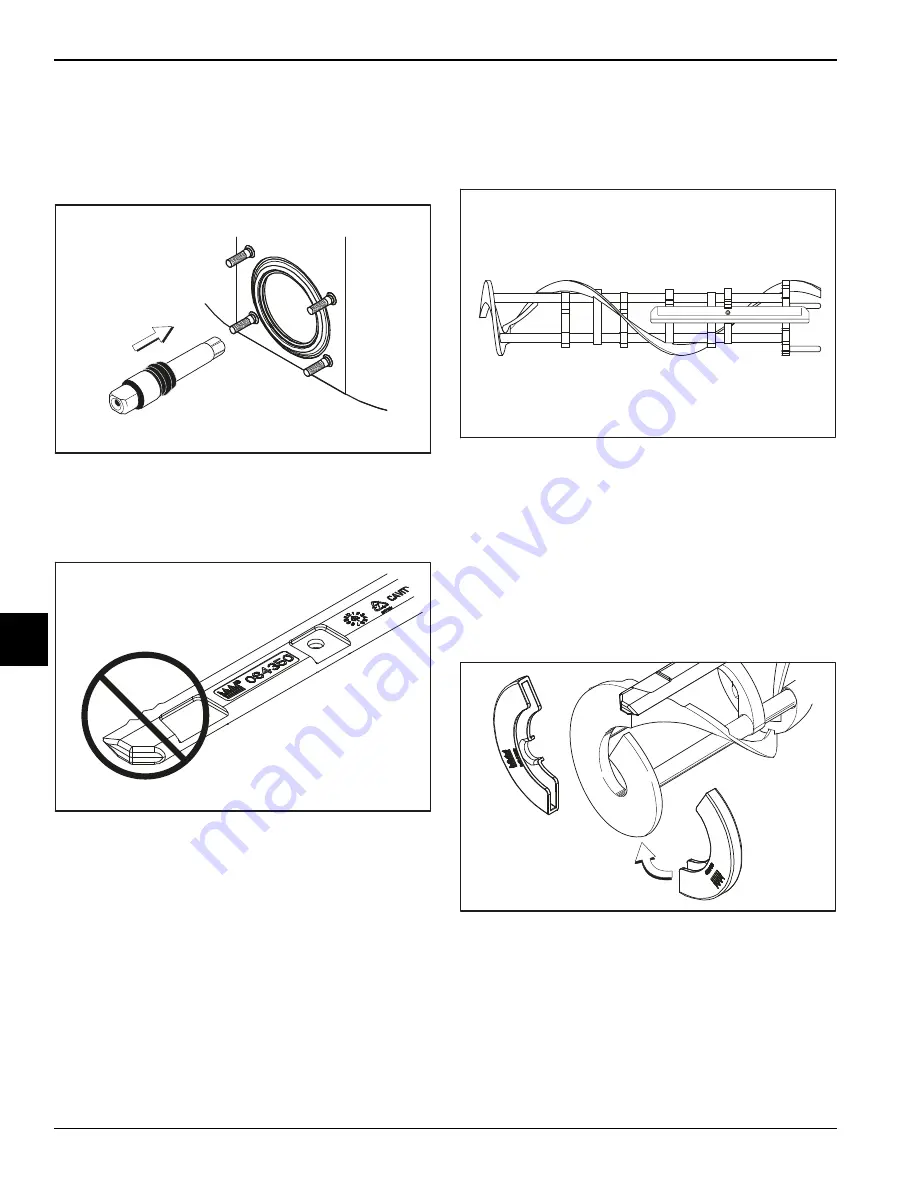

Insert the driveshaft into the freezing cylinder (hex

end first) and into the rear shell bearing until the seal

fits securely over the rear shell bearing. Engage the

hex end firmly in the drive coupling. Make sure the

driveshaft fits into the drive coupling without binding.

Figure 6-2

3.

Before installing the beater assembly, inspect the

scraper blades for any signs of wear or damage. If a

scraper blade is nicked or worn, replace both blades.

Figure 6-3

4. Place the rear scraper blade over the rear holding pin

on the beater.

Note:

The hole on the scraper blade must fit

securely over the pin to prevent costly damage.

Figure 6-4

5. Holding the rear blade on the beater, slide it halfway

into the freezing cylinder. Install the front scraper

blade over the front holding pin.

6. Before installing the beater shoes, check them for

any nicks, cracks, or signs of wear. If any defects are

present, replace the beater shoes.

7. If the beater shoes are in good condition, install

them.

Figure 6-5

8. Slide the beater assembly the rest of the way into the

freezing cylinder.

Make sure the beater assembly is in position over the

driveshaft. Turn the beater slightly to be certain it is

properly seated. When in position, the beater should

not protrude beyond the front of the freezing cylinder.

11230

11529

11256

11532

Summary of Contents for C706

Page 8: ...1 4 TO THE INSTALLER Model C706 To the Installer 1 Notes ...

Page 14: ...3 4 SAFETY Model C706 Safety 3 Notes ...

Page 36: ...6 14 OPERATING PROCEDURES Model C706 Operating Procedures 6 Notes ...

Page 42: ...8 4 TROUBLESHOOTING GUIDE Model C706 Troubleshooting Guide 8 Notes ...

Page 44: ...9 2 PARTS REPLACEMENT SCHEDULE Model C706 Parts Replacement Schedule 9 Notes ...

Page 48: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C706 Limited Warranty on Equipment 10 Notes ...

Page 52: ...11 4 LIMITED WARRANTY ON PARTS Model C706 Limited Warranty on Parts 11 Notes ...