USER INTERFACE

5-7

Models C709 & C717

User Interface

5

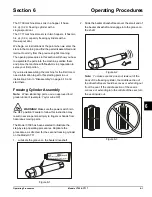

WARNING!

DO NOT

attempt to draw product or

disassemble the machine during the Heat Treatment

Cycle (if equipped). The product is hot and under

extreme pressure. Severe burns from hot product may

result if this instruction is not followed.

In the Heat cycle, the mix temperature in the hopper and

freezing cylinder must be raised to 151°F (66.1°C) within

90 minutes.

When the heating phase is complete, the machine goes

into the holding phase of the cycle. The holding phase

will keep the temperature above 151°F (66.1°C) for a

minimum of 35 minutes.

The final phase of the Heat Treatment cycle is the cooling

phase. The machine must cool the mix below 41°F (5°C)

within 120 minutes.

When the entire Heat cycle has been completed, the

Heat key will no longer be illuminated. The machine will

enter the Standby mode (Standby key illuminates). The

machine can be placed in Auto or left in Standby.

To comply with health codes, Heat Treatment system

machines must complete a Heat Treatment cycle daily

and must be disassembled and brush-cleaned according

to the frequency specified by your federal, state, or local

regulatory agencies. Please consult your governing food

code to determine the maximum number of days allowed

between brush-clean cycles.

Brush-cleaning is the normal disassembly and cleaning

procedure found in this Operator’s Manual. Failure to

follow these guidelines will cause the control to lock the

machine out of the Auto mode.

If the Heat Treatment cycle fails, the screen will display a

failure message and return the machine to the Standby

mode.

Always comply with local guidelines for the maximum

number of days allowed between brush-clean cycles.

Freezer Locks

There are two types of machine lock conditions that can

occur: hard lock or soft lock. A hard lock requires the

machine to be disassembled and brush-cleaned. A soft

lock can be corrected by either disassembling and

brush-cleaning the machine or by starting another Heat

Treatment cycle.

Hard Lock

There are two causes of a hard lock failure. The machine

will hard lock if either the Brush-Clean Timer has elapsed

or a thermistor failure (freezing cylinder or hopper)

occurred during a Heat cycle.

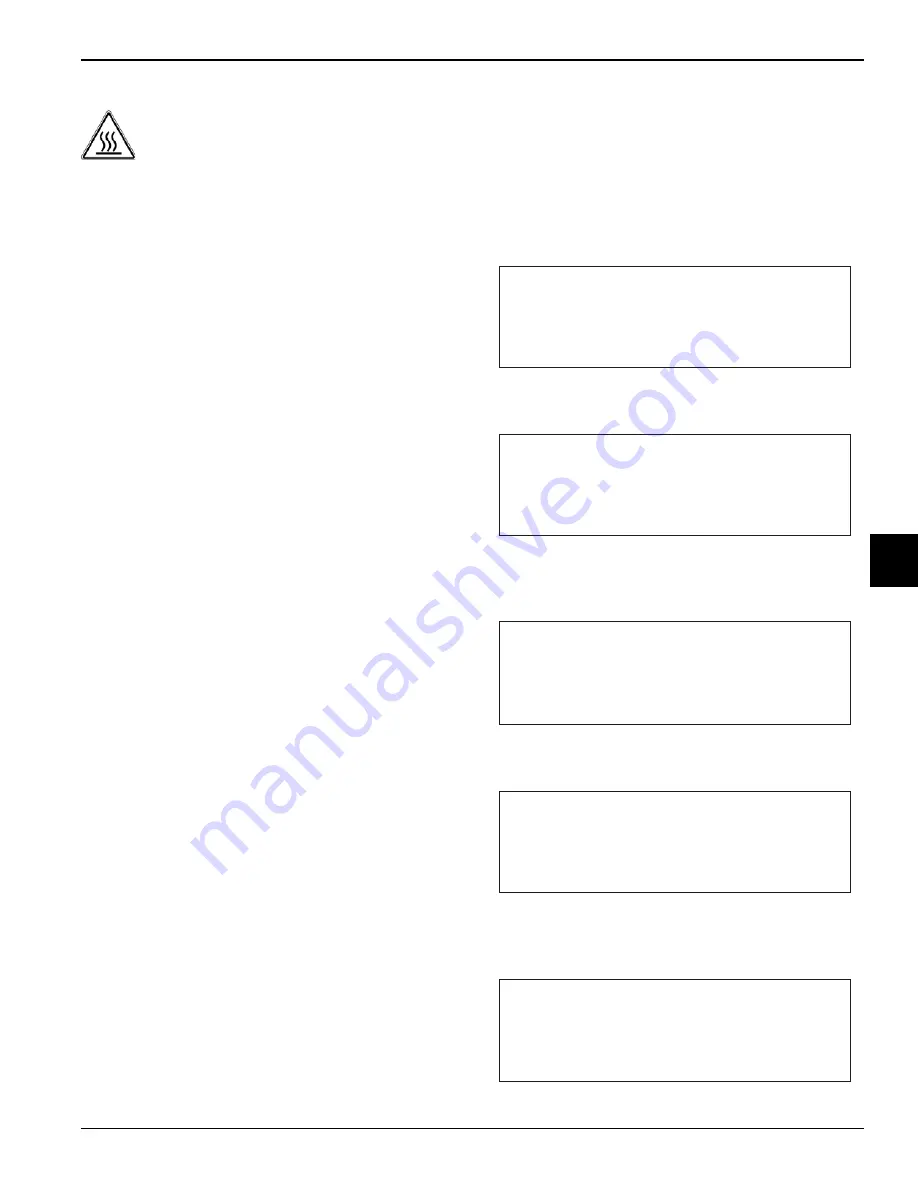

•

The following screen will be displayed if a Brush

Clean Cycle Time has occurred:

Pressing the SEL key will display the following

screen:

•

The following screen will display if there has been a

thermistor failure (freezing cylinder or hopper) during

the Heat Treatment process:

Pressing the SEL key will indicate which thermistor

caused the hard lock.

If the machine has hard locked and an attempt is

made to enter Auto mode, the machine will enter the

Standby mode and display the following message:

BRUSH CLEAN TIMEOUT

FREEZER LOCKED

CLEANING REQ'D

>

WASH TO BRUSH CLEAN

FREEZER LOCKED

SYSTEM FAULT

FREEZER LOCKED

SERVICE REQ'D

>

WASH TO BRUSH CLEAN

HOPPER THERM BAD

FREEZER LOCKED

FREEZER LOCKED

Summary of Contents for C709

Page 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Page 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Page 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Page 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Page 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Page 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...