OPERATING PROCEDURES

6-9

Models C709 & C717

Operating Procedures

6

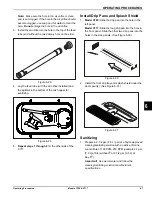

10. Return to the machine with a small amount of

sanitizing solution. Dip the door spout brush into the

sanitizing solution and brush-clean the door spout

and bottom of the draw valve.

Note:

To ensure sanitary conditions are

maintained, brush-clean each item for a total of 60

seconds, repeatedly dipping the brush in sanitizing

solution.

11.

Repeat steps 1 through 10

for the other side of the

C717.

Priming

Note:

Use only

fresh

mix when priming the freezer.

1.

With a pail beneath the door spout(s), open the draw

valve. Pour 2-1/2 gal. (9.5 L) of

fresh

mix into the mix

hopper and allow it to flow into the freezing cylinder.

This will force out any remaining sanitizing solution.

When full-strength mix is flowing from the door spout,

close the draw valve.

Important!

Failure to remove all sanitizing solution

may result in damage to the freezing cylinder.

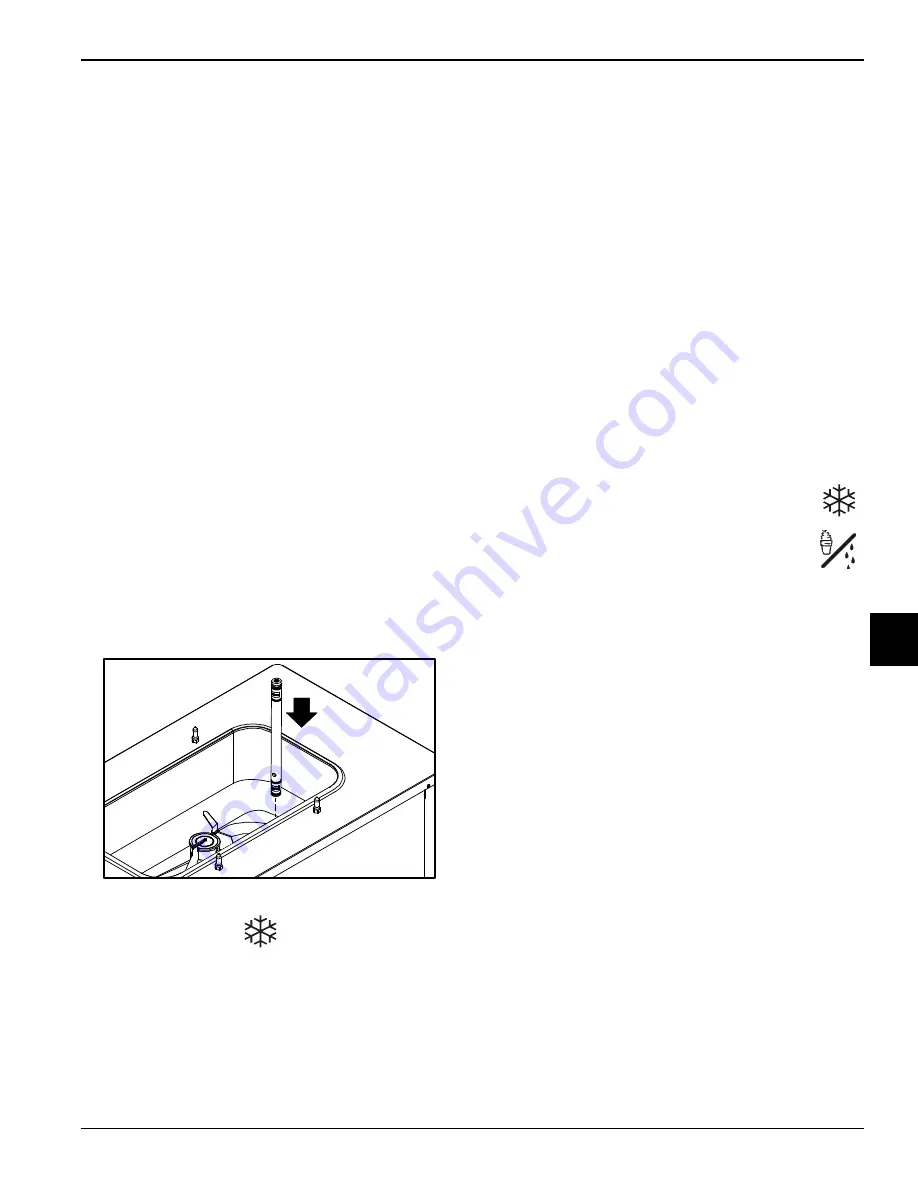

2.

When mix stops bubbling down into the freezing

cylinder, install the mix feed tube (end with the mix

delivery hole in its side) in the mix inlet hole in the mix

hopper.

Figure 6-36

3.

Select the Auto key

.

4.

Fill the hopper with

fresh

mix and place the mix

hopper cover in position.

5.

Repeat steps 1 through 4

for the other side of the

C717.

Daily Closing Procedures

Important!

This procedure must be performed once

daily.

The function of the Heat Treatment cycle is to destroy

bacteria by raising the temperature of the mix in the

freezing cylinder and hopper to a specified temperature

for a specified period of time, and then bringing the

temperature back down low enough to retard spoilage.

The Heat Treatment cycle will start at the time designated

in the Auto Heat time.

Important!

The level of mix in the mix hopper(s) must be

up to the fill line on the agitator paddle(s). (The MIX LOW

light must not be on.)

Note:

If the BRUSH CLEAN COUNTER display has

counted down to one day, do not add mix. The machine

must be disassembled and brush-cleaned within 24

hours.

The machine must be in the Auto mode (Auto key

illuminated) or in the Standby mode (Standby key

illuminated) before the Heat cycle may be started.

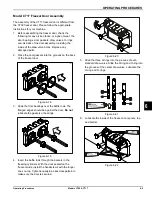

1. Remove the hopper cover(s), drip pan(s), front drip

tray, and splash shield. Take them to the

three-compartment sink for cleaning and sanitizing.

Important!

Make sure your hands are clean and

sanitized before performing these next steps.

2. Remove the air orifice(s), the feed tube(s), and the

agitator(s) from the mix hopper(s). Take these parts

to the sink for cleaning and sanitizing.

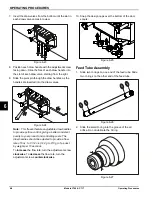

3. Rinse the parts in cool, clean water.

4. Prepare a small amount of a Taylor-approved

cleaning/sanitizing solution with an active chlorine

concentrate of 100 PPM to 200 PPM.

Important!

Use warm water and follow the cleaning/

sanitizing solution manufacturer's specifications.

5. Brush-clean the parts in this solution.

6. Place the front drip tray, splash shield, and air

orifice(s) on a clean, dry surface to air-dry overnight

or until the Heating cycle is complete.

12326

Summary of Contents for C709

Page 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Page 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Page 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Page 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Page 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Page 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...